Ever wonder what it takes to build the massive infrastructure that supports our communities? That's the world of heavy civil construction—the design, creation, and upkeep of the foundational systems we all depend on. We're talking about everything from highways and bridges to dams and underground utility networks. These aren't just construction projects; they're the lifelines of modern society.

What Is Heavy Civil Construction

Think of a city as a living, breathing organism. The buildings we see—offices, homes, shops—are just the skin. Heavy civil construction is what builds the skeleton and the circulatory system that allow it to function.

This is the work that creates a community's core structure. It includes deep foundations for skyscrapers and the massive steel and concrete bones of bridges. It also involves laying the circulatory network: the underground water and sewer pipelines, the intricate web of roadways, and all the other systems that enable the flow of people, goods, and services.

Breaking Down the Terminology

The name itself gives you a good sense of its scope. The word "civil" points directly to its purpose—serving the civilian population. These aren't small, private projects. They are built for the public good and are usually managed by government agencies or large-scale public-private partnerships.

Then there's "heavy." This refers to the sheer scale and complexity of the work. It’s not just about using large machinery; it’s about moving mountains of earth, pouring thousands of tons of concrete, and installing enormous structural components. Everything—the equipment, the materials, the engineering—is on a massive scale.

Heavy civil construction is really about shaping the physical world to support modern life. It's where engineering principles are put into practice to create the essential, and often unseen, infrastructure that drives our economy and improves our quality of life.

The Scale of the Industry

The global impact of this sector is enormous and growing fast. The heavy and civil engineering construction market was valued at roughly $2.07 trillion in 2025. Projections show it climbing to nearly $2.49 trillion by 2029, with a huge chunk of that—about 44%—coming from highway, street, and bridge projects. You can dive deeper into the heavy and civil engineering market forecast on Business Wire.

This growth isn't surprising. There's a constant need to maintain and upgrade our public works. From the roads you drive on every day to the groundwork supporting our digital world—like data center pads and fiber optic conduit routes—heavy civil construction is the invisible force making it all possible.

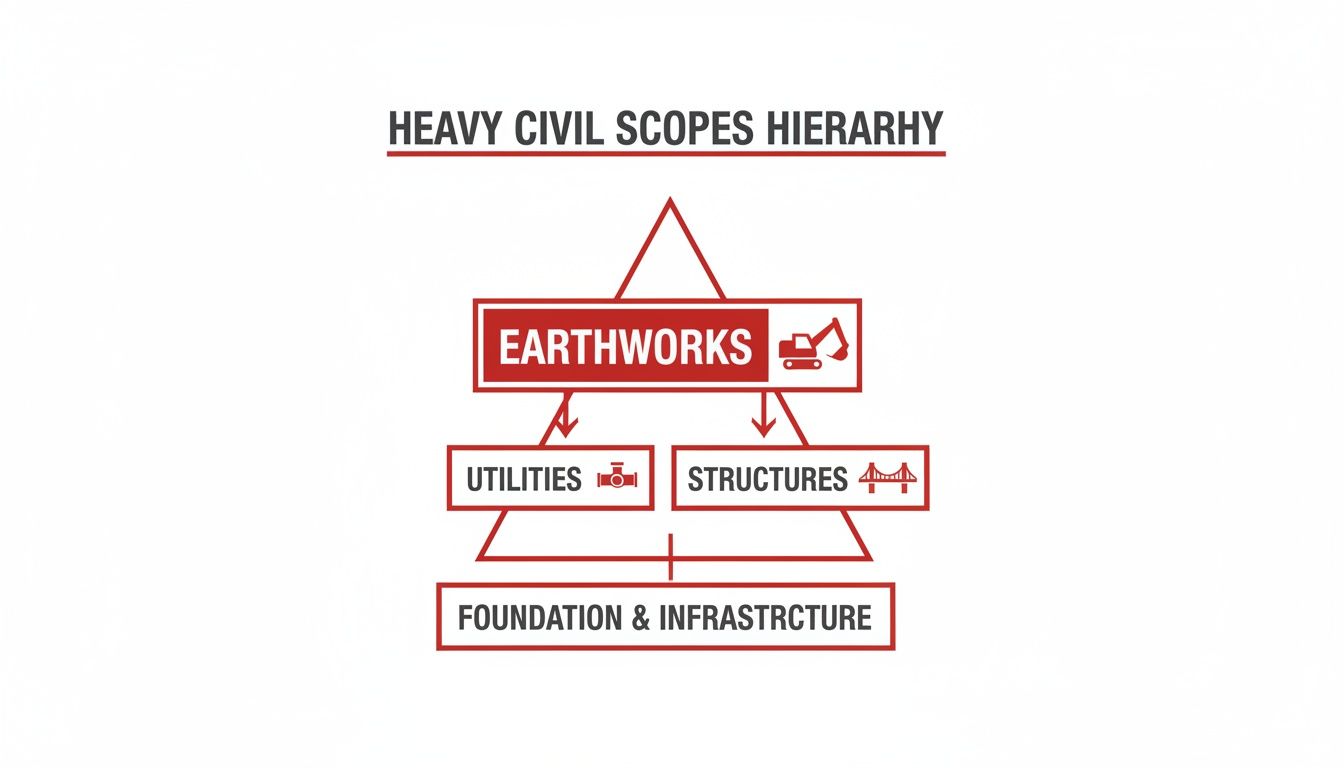

Understanding the Core Scopes of Work

Heavy civil construction is defined by its sheer scale and foundational role in our society. While no two jobs are ever exactly the same, most projects are built on a handful of core disciplines—the essential scopes of work that turn raw land into the functional infrastructure we all depend on.

Think of these scopes as the fundamental building blocks of a project. From literally moving mountains of earth to installing the hidden networks that power our modern lives, each one is a specialized craft. Getting a handle on them gives you a clear picture of what’s really happening behind the construction barriers.

Earthworks: Reshaping the Landscape

Before a single drop of concrete is poured or a pipe is set, the ground itself has to be ready. This is the world of earthworks, and it's the first critical step in almost every heavy civil project. It’s both an art and a science, involving the movement, shaping, and stabilization of massive amounts of soil and rock to create a solid platform for everything that follows.

This is a lot more than just digging holes. Earthworks is a precise, engineered process:

- Mass Excavation and Grading: This is where heavy iron—excavators, bulldozers, and scrapers—goes to work. They cut, fill, and sculpt the land to create the specific elevations and contours needed for a new highway, a data center pad, or a reservoir.

- Soil Stabilization: Sometimes the native soil just isn't strong enough. In these cases, we improve its properties by blending in additives like lime or cement, ensuring the ground can support enormous loads without failing.

- Compaction: Layer by layer, the soil is systematically compressed to increase its density and strength. This prevents the ground from settling later, which could crack roads or compromise entire foundations.

Get the earthworks wrong, and even the best-designed structure is doomed. This is the unglamorous but absolutely essential work that guarantees long-term stability from the ground up.

Underground Utilities: The Hidden Infrastructure

Deep beneath our feet lies a complex web of arteries and veins that deliver the services we take for granted. Installing these systems is another core function of heavy civil construction, broadly known as underground utilities. It’s work that becomes completely invisible once a project is finished, but it’s vital for public health, safety, and modern communication.

A single project often involves juggling multiple, distinct utility systems within crowded corridors, all while navigating existing infrastructure.

Laying underground utilities is like performing surgery on a city. It demands precision, careful planning, and a deep understanding of how different systems must coexist to keep the community functioning smoothly.

Some of the key systems include:

- Water and Sewer Lines: This is the backbone of public sanitation—installing the large-diameter pipes that bring us fresh water and carry away wastewater.

- Storm Drainage Systems: A network of pipes, culverts, and inlets designed to manage rainwater. A well-designed storm system prevents flooding, protects property, and keeps pollutants out of our waterways.

- Communication Conduits: This involves laying the protective duct banks that house the fiber optic cables powering our digital world.

Roadways and Structures: Creating Connections

The most visible part of heavy civil construction is building the transportation networks that connect our communities and move our economy. This scope covers the roadways and structures that we drive on every day. It's where raw materials like asphalt, concrete, and steel come together to create durable, safe, and efficient infrastructure.

This is far more than just laying down pavement. It includes everything from multi-lane interstate highways and complex urban interchanges to massive bridges that span rivers and valleys. The engineering here ensures these structures can handle constant traffic, harsh weather, and the test of time. A typical roadway project moves from sub-base preparation to asphalt or concrete paving, and finally to installing guardrails, signage, and lighting.

This table gives a quick breakdown of how these common scopes fit together.

Typical Heavy Civil Construction Scopes

| Scope of Work | Primary Function | Common Examples |

|---|---|---|

| Earthworks | Preparing and stabilizing the ground for construction. | Site grading, mass excavation, soil compaction. |

| Underground Utilities | Installing systems for water, waste, and data. | Water mains, storm drains, fiber optic conduits. |

| Roadways & Structures | Building transportation networks and their components. | Highway paving, bridge construction, retaining walls. |

Each of these core disciplines requires specialized skills, heavy equipment, and an incredible amount of planning. Working in concert, they transform engineering blueprints into the tangible, essential infrastructure we all rely on.

Navigating Project Costs and Timelines

Heavy civil projects are beasts of their own kind, not just in their sheer size but in their financial and logistical complexity. Getting a handle on costs and schedules isn't about following a simple checklist; it's about navigating a constantly shifting environment filled with variables. The budget for a major highway or dam isn't just a shopping list—it's a strategic forecast that has to bake in market volatility, resource availability, and the raw unpredictability of the work itself.

This demands a real-world understanding of the key drivers that can make or break a project. Things like the price of steel and concrete, the availability of specialized heavy equipment, and simply finding enough skilled hands to do the work create a high-stakes balancing act. One surprise, just one, can send ripples across the entire project, throwing both the budget and the timeline into chaos.

The infographic below shows just how interconnected everything is. Each phase is built on the last, meaning a delay in one area inevitably impacts all the others.

As you can see, you can't build solid structures without first getting the earthworks and utilities right. Success is a chain reaction, and so is failure.

Primary Cost and Schedule Drivers

When you get down to it, a few critical components hold the most sway—and the most risk—over any project's budget and timeline. Getting ahead of these is everything.

- Material Price Volatility: The cost of core materials like aggregate, asphalt, concrete, and steel can swing wildly depending on global supply chains and local demand. A sudden price spike can easily add millions to a project's cost if your procurement contracts aren't structured to account for it.

- Heavy Machinery Costs: These jobs depend on a massive fleet of specialized iron—excavators, graders, cranes, pavers, you name it. The costs to lease, fuel, maintain, and operate this equipment are a huge slice of the budget. When a critical machine goes down, you're not just paying for repairs; you're losing time and money every hour it sits idle.

- Skilled Labor Availability: Finding and keeping qualified operators, laborers, and foremen is a constant battle in this industry. Labor shortages don't just drive up wages; they can stall progress entirely if you can't field a full crew.

The Impact of Unforeseen Conditions

One of the biggest gambles in heavy civil work is what lies just beneath the surface. No matter how many geotechnical surveys you run, unforeseen site conditions can pop up the moment you break ground, causing major delays and cost overruns.

For instance, your crew might hit an unexpected ledge of solid rock that requires blasting or bringing in specialized drilling rigs that weren't in the original plan. Or they could discover unstable soil that needs extensive—and expensive—remediation before it can support a foundation. Worse yet is uncovering contaminated soil or groundwater, which can stop work dead in its tracks and trigger a complex, costly environmental cleanup.

Even the most buttoned-up project schedule is at the mercy of what's actually in the ground. Good risk management isn't about preventing every surprise; it's about having the people, equipment, and contingency plans ready to pivot when the inevitable happens.

This is exactly why seasoned contractors build contingencies right into their bids and schedules. While industry studies suggest global construction activity could jump by roughly 70% by 2040, the sector is also grappling with serious labor and productivity issues. As detailed in key trends in heavy highway construction from CMIC Global, an aging workforce and persistent skill gaps are a major source of schedule risk and cost escalation on big civil projects.

For telecom jobs, these surprises often look like unmarked utility lines or dense rock that makes trenching for fiber conduit a nightmare. This is where choosing the right partners makes all the difference. Experienced cable contractor companies have seen it all before and know how to anticipate and navigate these underground obstacles. At the end of the day, delivering complex infrastructure on time and on budget comes down to three things: smart planning, honest risk assessment, and clear communication.

Mastering Regulatory and Environmental Compliance

Success in heavy civil construction has less to do with moving dirt and pouring concrete than you might think. Long before the first excavator bucket breaks ground, every project has to navigate a dense maze of local, state, and federal regulations. This isn't just about paperwork; it's a critical risk management phase where one oversight can sideline a project for months, if not years.

Think of it as getting a pilot's flight plan approved. You can't just take off whenever you want. You need clearance from multiple authorities, each with its own rulebook, to guarantee a safe and successful journey. For a construction project, this means securing a thick stack of permits that grant you the legal right to build.

Demystifying the Permitting Labyrinth

The permitting process is where your project plans collide with public policy. Government bodies will scrutinize your designs to ensure they comply with everything from zoning laws and safety codes to environmental protections. It’s a deliberately slow-moving process that demands meticulous documentation and constant, proactive communication.

Nearly every heavy civil construction project will require some combination of these permits:

- Land Disturbance Permits: These are almost always the first hurdle. Before any significant earthmoving starts, you need to prove you have a solid erosion and sediment control plan.

- Environmental Permits: If your project so much as touches a wetland, waterway, or protected habitat, you'll need authorization from agencies like the Environmental Protection Agency (EPA).

- Building and Zoning Permits: These local approvals are essential for making sure your project fits into the community's master plan and land-use regulations.

Trying to bypass this process simply isn't an option. The consequences are steep: hefty fines, stop-work orders, and severe damage to your company’s reputation.

Managing Critical Environmental Concerns

Today, construction is as much about building responsibly as it is about building at all. Environmental compliance is baked into the DNA of any modern project, with a sharp focus on minimizing the impact on the natural world around it. This requires a genuine understanding of ecological sensitivities and historical preservation laws.

A few key environmental areas always take center stage:

- Stormwater Management: Every project needs a Stormwater Pollution Prevention Plan (SWPPP). This is the playbook for controlling runoff and keeping sediment or other contaminants out of nearby streams and rivers.

- Endangered Species Protection: If a protected plant or animal calls your project site home, you’ll be working closely with wildlife agencies to create mitigation plans that leave their habitats undisturbed.

- Historical and Cultural Sites: Before you dig, archeological surveys are often required. The goal is to ensure the project doesn't accidentally destroy undiscovered artifacts or sacred grounds.

Environmental compliance is the project's social license to operate. It demonstrates a commitment to stewardship that protects natural resources for future generations while allowing essential infrastructure development to proceed.

The Challenge of Securing Right-of-Way

Of all the hurdles, securing the Right-of-Way (ROW) is often the most unpredictable and time-consuming. ROW is the legal right to access and build on land you don't own. For linear projects like highways or fiber optic routes, this can mean negotiating with dozens, or even hundreds, of individual landowners.

Getting ROW is a delicate dance of appraisals, negotiations, and sometimes legal action through eminent domain. It frequently becomes the longest lead-time item on a project schedule because it's driven by human factors and legal timelines far outside a contractor's control. A single landowner holding out can force a complete reroute, adding huge costs and delays.

This is exactly why experienced firms treat ROW acquisition as its own standalone project, often starting the process years before construction is even scheduled to begin.

How Heavy Civil Connects to Modern Telecom Infrastructure

When you think of heavy civil construction, images of massive bridges and sprawling highways probably come to mind. But its role in building our digital world is just as critical. The internet, our cellular networks, the cloud—it all feels invisible, but it relies on a huge physical foundation. It’s the heavy civil contractors who build that foundation, creating the "physical superhighways" our digital information travels on.

This is where two essential industries meet. Every video you stream, every call you make, depends on infrastructure that started with someone moving earth, digging a trench, or pouring concrete. The digital age is truly built on the same time-tested principles of solid engineering that have supported our communities for centuries.

Building the Backbone of Broadband

Fiber optic cable is the heart of modern connectivity. These hair-thin glass strands are the arteries of the internet, but they're useless if they're not protected and installed correctly. That's where heavy civil expertise comes in, laying the groundwork for network expansion.

And it’s a lot more than just digging a ditch. Crews have to perform incredibly precise trenching or directional boring to install conduits—the protective pipelines that shield delicate fiber cables from soil, water, and shifting ground. This work means navigating a complex underground maze of existing utilities, dealing with all kinds of soil conditions, and meeting strict local regulations, all while trying to keep public disruption to a minimum.

To see more on how this specialized work makes connectivity possible, you can explore our overview of broadband and telecom services.

Heavy civil work is the unseen first step for digital communication. It's the tough, physical labor that clears the path for data to travel at light speed, connecting homes, businesses, and entire communities.

Site Prep for Wireless and Data Centers

Our demand for data is exploding, which means we need more cell towers and colossal data centers. These critical facilities can’t just be dropped anywhere. They require extensive site preparation that falls squarely into the heavy civil domain, ensuring the stability, security, and long-term operation of our digital infrastructure.

Think about what it takes to build these hubs:

- Cell Tower Pads: Before a tower goes up, the site has to be perfectly graded. This means building stable access roads, excavating for massive concrete foundations, and installing proper drainage to protect all the sensitive electronics at the tower's base.

- Data Center Sites: The new hyperscale data centers are unbelievably large buildings that need perfectly flat, stable ground. This often involves mass excavation and soil stabilization across many acres to support foundations that can handle millions of pounds of servers and cooling equipment.

In both cases, the success of the high-tech facility rests entirely on the quality of the "low-tech" groundwork. Without expert site development, the billions invested in servers and antennas would be at risk. This prep work is a core skill for heavy civil firms, making them an essential partner in expanding our digital world.

Tackling Unique Telecom Challenges

Bringing heavy civil work into a telecom project creates a unique set of problems that demand specialized skills and quick thinking. Unlike a new highway cutting through open land, telecom infrastructure is usually retrofitted into dense urban and suburban areas already jam-packed with utilities.

Contractors run into a few key hurdles:

- Navigating Crowded Corridors: Urban rights-of-way are a tangled web of water, sewer, gas, and electrical lines. Crews have to use advanced methods like hydro-excavation and precise utility locating to install new conduits without causing a catastrophic outage.

- Minimizing Public Disruption: Laying miles of fiber through established neighborhoods requires smart traffic management, noise control, and excellent site restoration to keep the community on your side and comply with local rules.

- Adapting to Varied Terrain: A single fiber route can go from solid rock that needs special drilling equipment to soft soils that need to be reinforced. This demands a versatile fleet of machinery and experienced operators who know how to switch gears on the fly.

Successfully managing these challenges shows just how much modern heavy civil work has evolved. It’s no longer just about brute force; it’s about surgical precision, strategic planning, and knowing how to build for the future without breaking the present.

Prioritizing Safety and Quality Control

In the world of heavy civil construction, safety and quality aren’t just line items on a project plan—they’re the bedrock of everything we do. When you’re dealing with massive equipment, deep excavations, and crews working inches from live traffic, there is absolutely no margin for error. A deep-seated commitment to rigorous protocols isn't optional; it's the only way to protect our people and the public.

This commitment has to go far beyond a toolbox talk or a generic checklist. It's about instilling a culture where everyone understands the very real dangers of the work. Every single day, our crews face significant risks that demand specialized training and an unwavering focus on the details.

Core Pillars of Site Safety

On any given project, we're not just hoping for safety; we're actively managing it through several critical focus areas. Each one is designed to head off a specific, high-consequence risk that's just part of the job in heavy civil work.

These pillars of safety include:

- Trench and Excavation Safety: An open trench can be one of the most dangerous places on a job site. That's why proper shoring, sloping, and daily inspections aren't just best practices—they're non-negotiable rules to prevent a catastrophic collapse.

- Heavy Equipment Operation: Our operators are highly trained and certified for a reason. We enforce strict protocols for machine inspections, insist on clear communication with ground personnel, and establish defined work zones to prevent tragic accidents.

- Traffic Management: Working on an active roadway requires a meticulously detailed traffic control plan. This isn't just a few cones; it involves the strategic use of barriers, signage, and flaggers to create a safe and effective buffer between our crews and moving vehicles.

Ensuring Quality from the Ground Up

While safety protects people, Quality Control (QC) protects the long-term integrity of the infrastructure itself. Think of QC as the systematic process of making sure that every single component of the project—from the soil compaction under a road to the concrete in a foundation—meets the exact engineering specifications.

This isn't something you do at the end. It's a continuous, documented effort that happens at every single stage of the build.

Quality control is the project's immune system. It’s constantly testing and verifying materials and workmanship to catch defects before they can ever compromise the entire structure. It’s the ultimate investment in building infrastructure that lasts for generations.

A strong QC program is built on a few key activities. First is materials testing, where we send samples of soil, aggregate, and concrete to a lab to confirm they have the right strength and durability. Next, regular site inspections are performed to verify that installation methods are a perfect match for the engineering plans.

For example, a quality inspector will ensure that underground conduits for fiber optic cables are laid at the correct depth with the proper backfill—a detail that’s absolutely vital for long-term network reliability. You can see just how much precision goes into this kind of work in our guide on how to splice fiber optic cable.

Finally, meticulous documentation creates a permanent, auditable record of compliance, proving that every standard was met. Taken together, these practices guarantee that public infrastructure is not only built safely but built to endure.

Answering Your Questions About Heavy Civil Construction

When you're dealing with massive infrastructure projects, it's natural to have a few questions. Let's clear up some of the most common ones that come up in the heavy civil world. Think of this as a quick reference guide to help lock in the key ideas we've covered.

What's the Real Difference Between Heavy Civil and Commercial Construction?

The easiest way to get it is to think about function vs. form.

Heavy civil construction is all about building the horizontal infrastructure that makes modern life possible—things like highways, bridges, dams, airports, and the water and sewer lines running under our feet. These projects are built for the public good and are designed to serve entire communities.

Commercial construction, on the other hand, is about building the vertical structures where people live, work, and shop. We're talking office buildings, retail stores, schools, and warehouses. So, while both fields might pour concrete and use skilled crews, heavy civil builds the networks that connect everything, and commercial builds the places we go.

What Are the Biggest Headaches on a Heavy Civil Project?

The challenges in heavy civil are almost always tied to the sheer scale and the number of unknowns you face out in the field. The biggest hurdles usually fall into a few key areas:

- Surprises in the Ground: You can do all the geotechnical borings you want, but hitting a massive, unexpected ledge of rock or discovering that the soil is far less stable than predicted can throw a wrench in your schedule and budget.

- The Permitting Maze: Getting the green light for these projects isn't simple. You're often navigating a complex web of environmental permits, right-of-way approvals, and sign-offs from multiple local, state, and federal agencies. It's a logistical beast.

- Market Volatility: The price of steel, concrete, and fuel can swing wildly, and finding enough skilled equipment operators and laborers is a constant struggle. These two factors create major financial and scheduling risks that you have to manage from day one.

This is why meticulous planning and having a solid risk management strategy aren't just nice-to-haves; they're absolutely critical to keeping a project on track.

How Is Technology Changing How We Build Infrastructure?

Technology is having a huge impact, moving us away from old-school manual methods toward tools that give us far more accuracy, safety, and control.

Technology isn't just a gimmick anymore; it's becoming a fundamental part of how we operate. Things like GPS-guided machinery, drone surveys, and powerful project management software are completely changing how infrastructure gets built, leading to better results and safer sites.

For instance, a bulldozer or grader guided by GPS can shape the earth to exact engineering specs with almost no need for rework. We now use drones to conduct site surveys in a fraction of the time it used to take, monitor daily progress, and perform safety checks. This tech integration helps teams juggle complex schedules, keep costs in line, and ultimately deliver a higher-quality final product.

At Southern Tier Resources, we blend decades of hands-on expertise with the right technology to build the reliable infrastructure our connected world relies on. Whether it's foundational site work or a complex telecom network deployment, our teams are ready to get it done. To see how we can help on your next project, learn more at the Southern Tier Resources website.