Cellular tower maintenance is all about the proactive inspection, repair, and general upkeep of your telecom infrastructure. It’s a disciplined process that goes way beyond just fixing what’s broken. The real goal is to prevent outages before they even have a chance to happen by managing everything from the tower's structural integrity down to the performance of its electronic gear. Ultimately, this framework is what keeps millions of users connected without a hitch.

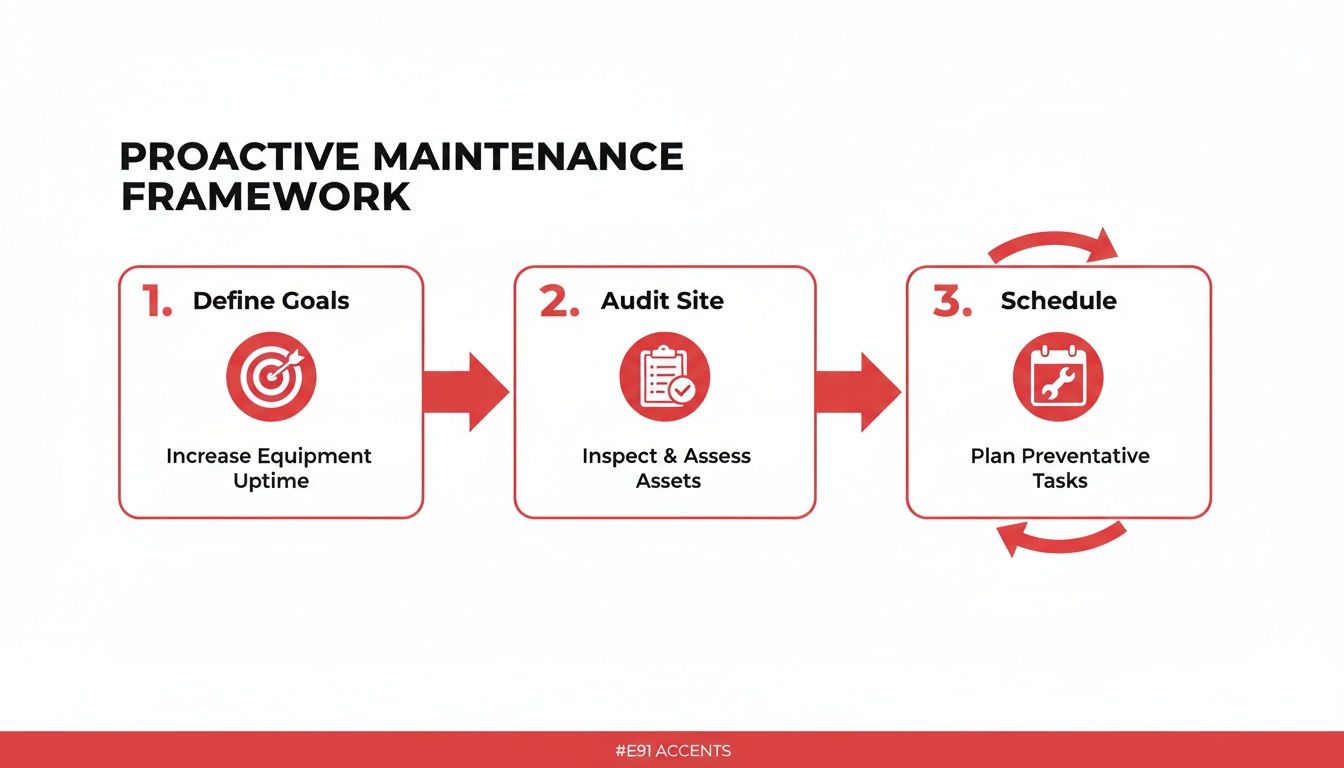

Building Your Proactive Maintenance Framework

If there's one shift you can make to modernize your tower management, it's moving from a reactive "break-fix" model to a proactive one. Sticking to a reactive approach—where you only dispatch crews after a failure—is a recipe for expensive downtime, sky-high emergency labor rates, and a black eye on your reputation.

A proactive framework, on the other hand, is built on foresight and a deep, practical understanding of your network assets.

The idea is to create a system that sees problems coming, extends the life of your equipment, and keeps the network humming at peak performance. This isn't just about scheduling routine checks; it’s about building an entire operational philosophy around resilience. As you get started, it’s worth taking a moment to delve into the core differences between predictive and preventive maintenance to decide which elements fit your strategy best.

Define Clear Operational Goals

Before a single wrench is turned, you have to know what success looks like. Your goals are the North Star for your entire maintenance program, guiding every decision on budgeting, scheduling, and allocating resources. Get specific and be realistic.

Here are a few common goals I've seen in the field:

- Achieving Uptime Targets: The industry benchmark is often 99.99% network uptime, or "four nines." That translates to less than an hour of total downtime per year.

- Ensuring Regulatory Adherence: This means a firm commitment to zero violations from bodies like the FAA (for tower lighting) and OSHA (for worker safety).

- Controlling Operational Costs: A smart goal is to reduce emergency maintenance calls by a set amount, like 30% within the first year, by investing upfront in preventative tasks.

Assemble the Right Team

A maintenance program is only as good as the people running it. You need a team of specialists who know their roles inside and out. Without the right crew, even the most brilliant plan is just a piece of paper.

These are the key players you'll need:

- Network Engineers: They're the brains of the operation, analyzing performance data, spotting systemic issues, and planning for future upgrades or equipment swaps.

- Certified Tower Climbers/Technicians: These are your hands-on experts. They're the ones up on the steel, performing physical inspections, making repairs, and installing new hardware.

- Asset Managers: These folks track every single piece of equipment across all your sites. They manage inventory and oversee the entire lifecycle of your components, from installation to decommissioning.

This simple flow shows how a structured approach ensures your maintenance activities are driven by data and purpose, not just arbitrary checks on a calendar.

Conduct a Comprehensive Site Audit

You can't maintain what you don't know you have. A thorough site audit is the bedrock of your program, creating a complete inventory of every single asset at each tower. This baseline is absolutely critical for creating realistic schedules and budgets. It gives you the ground truth you need to plan effectively.

A complete audit should catalog every major component, its condition, age, and any previous maintenance history. This creates an invaluable database for future decision-making and performance tracking.

The audit means documenting everything from the ground up—antennas, radios, cabling, connectors, power systems (don't forget batteries and generators), and all the structural steel. For a closer look at the specifics, you can find more information at https://southerntierresources.com/goodscode/lifetime/1899391065. This initial data-gathering phase provides the clarity required to build a maintenance plan that genuinely protects your network for the long haul.

Crafting Your Tower Inspection and Maintenance Cadence

A maintenance program is only as good as the schedule it runs on. Without a well-defined and consistently executed rhythm, you're always reacting to problems instead of getting ahead of them. Building this schedule isn’t just about putting dates on a calendar; it’s a strategic process that balances risk, cost, and the real-world operational demands of your network.

The whole point is to create a multi-tiered system where different components get the right kind of attention at the right time. Some parts of a tower site just need a quick look-over every few months. Others demand a detailed, hands-on assessment once a year. This layered approach ensures you’re putting your resources—both people and money—where they’ll make the biggest difference.

Differentiating Inspection Frequencies

Not every maintenance task carries the same weight. A critical first step is to categorize your inspections based on how deep they need to go and how often they need to happen. This tiered structure is really the backbone of any solid maintenance program.

I like to think of it in three main layers:

Routine Visual Inspections (Quarterly): These are your frequent, high-level health checks. A tech does a ground-level walk-around, looking for the obvious stuff: vandalism, overgrown vegetation, visible rust, or a busted fence. It's a quick but essential first line of defense.

Comprehensive Component Checks (Bi-Annually or Annually): This is a much more involved visit. Here, you’re testing backup power systems, checking HVAC units in the shelters, inspecting grounding systems for integrity, and making sure all site lighting is up to FAA code.

In-Depth Structural Assessments (Every 1-3 Years): This is the most demanding tier, almost always requiring certified climbers. They perform a top-to-bottom physical inspection of the tower itself, checking bolt torque, assessing the condition of welds, and hunting for any sign of metal fatigue or corrosion. Per the Telecommunications Industry Association (TIA) standards, you're typically looking at every three years for guyed towers and every five for self-supporting structures.

This structured approach is what keeps small, easily fixable problems from snowballing into major, service-impacting failures. It fundamentally shifts your team from constantly fighting fires to methodically preventing them.

Building Your Actionable Maintenance Calendar

Once you've got your tiers defined, you can start building out a real calendar. The trick is to schedule tasks logically throughout the year, thinking about things like weather, crew availability, and potential service interruptions. A well-planned calendar avoids bottlenecks and creates a steady, predictable workflow.

A great maintenance calendar does more than just list tasks; it becomes a predictive tool. By tracking findings over time, you can start to see patterns and anticipate when certain components will likely need attention before they fail.

This field is only getting more important. The cellular tower management market, which covers all these critical activities, was valued at USD 2.74 billion and is expected to climb to USD 4.18 billion by 2032. That growth underscores the massive industry-wide investment in reliability. You can read the full research on the cell tower management market to see the trends driving this focus.

Here’s a practical schedule you can adapt for your own operations.

Sample Cellular Tower Maintenance Schedule

This tiered schedule provides a solid starting point for building out your annual maintenance plan. It breaks down tasks by frequency, ensuring that nothing gets overlooked while also focusing resources efficiently.

| Frequency | Task Type | Key Activities | Purpose |

|---|---|---|---|

| Quarterly | Site & Compound Check | Inspect fences and gates, check for pests, clear debris, perform basic vegetation management. | Ensure site security, safety, and prevent environmental damage to ground equipment. |

| Bi-Annually | Power & Grounding Systems | Test backup generator and battery health, inspect grounding connections, verify electrical panel integrity. | Guarantee power continuity during outages and protect equipment from electrical surges. |

| Annually | RF & Antenna Audit | Visually inspect antennas and cabling for damage, perform PIM (Passive Intermodulation) testing if issues are suspected. | Maintain optimal signal quality and network performance for end-users. |

| Every 1-3 Years | Full Structural Integrity | Conduct a climbing inspection to check bolts, welds, and structural members for corrosion or fatigue. | Uphold structural safety and compliance, preventing catastrophic tower failure. |

Ultimately, this calendar becomes your operational playbook. It ensures every critical component, from the foundation bolts to the antennas at the very top, gets the right level of attention at the right time. This methodical rhythm is the hallmark of a world-class maintenance operation.

Embedding Safety and Compliance into Daily Operations

In the world of cell tower maintenance, safety isn't just a box to check on a form. It's the core principle that dictates every single move we make on a job site. A rock-solid safety program is non-negotiable; it's the bedrock that protects your most valuable asset—your crew. This goes way beyond just avoiding fines. It's about building a culture where every technician feels responsible for their own safety and the safety of everyone around them.

This commitment also means navigating a complex web of regulations from agencies like the FAA and OSHA. Compliance is mandatory, and cutting corners here has severe consequences, ranging from crippling fines and project shutdowns to catastrophic accidents.

Core Safety Protocols Every Crew Must Master

Every tower presents unique hazards, but a handful of core safety protocols are the universal language of safe operations. These procedures have to be second nature for every tech before they even step foot on site. Mastering them is the first line of defense against the most common and dangerous incidents we see in the field.

These are the absolute essentials:

- Comprehensive Fall Protection: This is, without a doubt, the most critical element of tower work. It means the correct use, inspection, and maintenance of personal protective equipment (PPE) like full-body harnesses, lanyards, and positioning devices. Every climb must follow a 100% tie-off policy, meaning the climber is connected to the structure from the moment they leave the ground until they're safely back down. No exceptions.

- RF Exposure Management: Live cellular antennas emit radiofrequency (RF) radiation. Crews need to be trained to spot RF warning signs, use personal RF monitors, and understand the safe working distances to stay well within OSHA's exposure limits. This isn't just about immediate safety; it prevents long-term health risks.

- Electrical Safety and Lockout/Tagout (LOTO): Before anyone touches an electrical system, the power source must be completely de-energized and locked out. LOTO procedures are what ensure that equipment can't be accidentally powered back on while a technician is working, preventing devastating electrical shocks or electrocution.

Developing and Implementing Site-Specific Safety Plans

While those core protocols are universal, no two tower sites are the same. A generic, one-size-fits-all safety plan just won't cut it. An effective program demands a Site-Specific Safety Plan (SSSP) for each and every location, taking into account its unique environment, structure type, and the specific work being done.

This plan isn't a static document; it's developed before anyone even mobilizes. It details potential hazards—from overhead power lines to unstable ground—and lays out clear strategies to mitigate them. It also must include emergency response procedures, identifying the nearest hospital and listing contact info for all key personnel.

A critical part of any SSSP is the daily pre-climb check. This isn't a formality. It's a mandatory huddle where the crew reviews the day's tasks, inspects their gear, and discusses any new or unexpected site conditions. It’s the final go/no-go decision before the climb begins.

Verifying your team's qualifications is just as important. Technicians should hold current certifications from respected bodies like the National Wireless Safety Alliance (NWSA) or the Society of Professional Rope Access Technicians (SPRAT). These credentials are tangible proof of a tech's competence in climbing safety and rescue. You can find more details on crucial occupational safety and health topics that are vital for keeping your work environment safe.

Navigating the Regulatory Landscape

Compliance is not optional. The cell tower industry operates under a strict set of rules designed to protect the public and ensure reliable communications. Understanding and following these regulations is a primary function of any maintenance program.

Key regulatory bodies and their turf include:

- Federal Aviation Administration (FAA): The FAA sets the standards for tower lighting and marking to make sure aircraft can see them. This covers everything from paint patterns (the classic alternating orange and white) to the operation of lighting systems, which must be monitored constantly for outages.

- Federal Communications Commission (FCC): The FCC is in charge of RF exposure limits and equipment operation. Staying compliant ensures your towers operate within safe broadcast parameters and don't cause interference with other signals.

- Occupational Safety and Health Administration (OSHA): OSHA governs all aspects of worker safety on site, from fall protection and hazard communication to electrical safety. Their regulations are the law of the land, and violations carry serious penalties.

Beyond the federal level, you also have to contend with local zoning ordinances and environmental regulations. These can affect everything from noise levels during work to how you manage vegetation around the site. A failure to comply doesn't just risk a fine—it damages your company's reputation and can jeopardize your ability to operate at all. A culture of safety and compliance is your best insurance policy.

Getting a Handle on Costs and Boosting Efficiency

Let's be honest: cellular tower maintenance is a massive line item on any operator's budget. But it doesn't have to be a runaway train. With the right approach, you can rein in costs and get more out of every dollar spent, all without compromising the quality of your network or the safety of your crews.

The secret is to stop just spending money and start making smart, data-backed investments in your infrastructure. That journey begins with a hard look at where the money is actually going.

Breaking Down Your Primary Cost Drivers

Before you can build a realistic budget, you need to dissect your spending. While every operation is unique, I've found that a few key expenses consistently eat up the lion's share of maintenance budgets. If you can get these under control, you're already winning.

Here are the usual suspects:

- Skilled Labor: Certified tower climbers aren't just general laborers; they're highly skilled pros, and their compensation reflects that. The real budget-killers are the emergency call-outs. A late-night climb in a storm will send your labor costs through the roof.

- Specialized Equipment: This is everything from the crane you rent for a heavy antenna swap to the sophisticated PIM (Passive Intermodulation) analyzers needed for troubleshooting. These tools are expensive to buy, and their ongoing calibration and upkeep add to the total cost of ownership.

- Site Access and Logistics: Just getting to the tower can be a major expense, especially for remote sites. You have to factor in fuel, vehicle wear-and-tear, and sometimes even specialized transport like ATVs or helicopters.

When you meticulously track these core expenses, you can finally move from a reactive, "put out the fire" spending model to a proactive financial strategy. It empowers you to put your resources where they’ll make the biggest difference for network reliability.

The Critical Difference: CapEx vs. OpEx

A classic budgeting mistake I see all the time is mixing up Capital Expenditures (CapEx) and Operational Expenditures (OpEx). Keeping them separate is fundamental to any sound financial planning for a maintenance program.

- CapEx (Capital Expenditures): These are the big, long-term investments that add real value to your physical assets. Think of a major project like upgrading an entire antenna system for 5G, replacing an old generator, or completing a significant structural reinforcement.

- OpEx (Operational Expenditures): This bucket covers all the day-to-day costs of just keeping the lights on. It’s your routine inspections, generator fuel, replacement parts for minor fixes, and the salaries for technicians doing scheduled maintenance.

Understanding this distinction is key to forecasting accurately and justifying bigger projects. For example, a well-planned CapEx project to install energy-efficient power systems can lead to a direct, measurable drop in your long-term OpEx.

Finding Real-World Cost-Saving Opportunities

Once you have a clear picture of your budget, you can start hunting for real savings—without just cutting corners. The goal here is to become more efficient, not just cheaper. You'd be surprised how small operational tweaks can lead to big savings down the line.

Power consumption is a huge one, especially for off-grid sites. It's a massive challenge across the industry; telecom towers globally burn over 2 billion liters of diesel every year for backup power. For some rural networks, this can account for 40% to 50% of total operational costs while leaving a serious carbon footprint. If you want to dive deeper into this, Coherent Market Insights has some great data where you can discover more insights about the telecom towers market.

Here are a few actionable ways to get started:

- Move Toward Predictive Maintenance: By investing in remote monitoring tech like IoT sensors, you can spot potential failures before they bring a site down. This simple shift dramatically cuts down on expensive emergency repairs and the revenue loss that comes with downtime.

- Embrace Energy-Efficient Solutions: Swapping out old diesel generators for hybrid systems, solar arrays, or modern high-efficiency batteries is a game-changer. It slashes fuel and maintenance spending and usually delivers a fantastic return on investment.

- Renegotiate Your Vendor Contracts: Don't just auto-renew your service level agreements (SLAs). Get on the phone with your maintenance contractors. You can often get better rates by bundling services for several sites or signing a longer-term agreement.

Using Technology for Smarter Maintenance Decisions

The old way of maintaining cell towers—relying on manual climbs and a calendar schedule—is quickly becoming a thing of the past. We're moving from a reactive, "fix-it-when-it-breaks" model to a much smarter, data-driven approach. By bringing modern tools into the mix, we can get a real-time, in-depth look at our infrastructure's health, which helps boost efficiency and stop failures before they ever happen.

This isn't just about adding fancy gadgets; it’s a fundamental shift that gives us a major operational edge. Instead of waiting for a critical component to fail and cause an outage, teams can now use data to spot the early warning signs. This allows for precise, well-timed repairs and smarter resource allocation, keeping the network strong and reliable.

Drones Taking Inspections to New Heights

One of the biggest game-changers for tower maintenance has been the widespread adoption of drones, or unmanned aerial vehicles (UAVs). For routine visual inspections, they dramatically cut down on the need for dangerous and slow manual climbs. A task that could take a climbing crew all day can often be done by a drone in about an hour.

These drones aren't just flying cameras. They're equipped with high-resolution imagers, thermal sensors, and sometimes even LiDAR scanners, giving us an incredible amount of detailed data. Engineers can safely analyze close-up shots of antennas, cabling, and structural bolts from the ground, spotting things like corrosion, loose hardware, or storm damage. Not only is this a huge leap forward for safety, but it also builds a fantastic digital history of the asset's condition over time.

The Power of IoT and Remote Monitoring

Beyond what we can see, the Internet of Things (IoT) gives us a constant, live feed of data straight from the tower site. Deploying a network of smart sensors means we can keep a 24/7 watch on our equipment without ever sending a technician.

This remote monitoring can cover a ton of critical systems:

- Structural Stress Sensors: These are great for detecting unusual strain or vibration from high winds or ice buildup, giving us an early heads-up about potential structural fatigue.

- Equipment Temperature Monitors: When placed on radios and power amplifiers, these sensors can flag overheating components—a classic sign of impending failure.

- Power System Analytics: IoT devices monitor the health of backup batteries and generators, making sure they're actually ready to kick in during a power outage. To learn more about keeping your gear in top shape, see our guide on the importance of routine equipment calibration.

This constant stream of data is what powers the next generation of maintenance strategy. It effectively turns every tower into a "smart" asset that tells you how it's feeling, which allows for a genuinely proactive approach to network care.

Predictive Maintenance with AI and Machine Learning

This is where all that data from drones and IoT sensors really starts to shine. Artificial intelligence (AI) and machine learning (ML) platforms can analyze these massive datasets to find subtle patterns that a human analyst would almost certainly miss. The system learns the signature of "normal" operation and can flag tiny deviations that point to a future problem.

This is the very essence of predictive maintenance. Instead of just preventing issues based on a fixed schedule, you can actually forecast them with surprising accuracy. For a deeper dive into this, it's worth exploring the applications of machine learning for predictive maintenance.

Fueled by AI and IoT, predictive maintenance is completely changing the game for cell tower upkeep, significantly reducing costs and downtime. Operators are using advanced analytics on sensor data to catch equipment problems well before they cause an outage. This is absolutely critical as data demands continue to explode—global mobile traffic hit a staggering 188 exabytes per month in Q3 2025. You can learn more about these telecom tower market findings and see how data is reshaping the entire industry.

Frequently Asked Questions About Tower Maintenance

Even with the best-laid plans, questions always come up in the field. When you're managing a portfolio of complex tower assets, you're bound to run into some common hurdles. Here are some of the most frequent questions we hear from network operators and infrastructure managers, along with our straight-to-the-point answers.

How Often Should a Cellular Tower Be Inspected?

There's no single answer here—the right inspection schedule really depends on the tower type and its environment. As a starting point, we always look to the standards set by the Telecommunications Industry Association (TIA).

A good baseline to work from is:

- Guyed towers: Plan for a comprehensive structural inspection every three years.

- Self-supporting towers: These generally need a full inspection every five years.

But that's just the baseline. If you have towers in harsh environments—think coastal areas getting blasted by salt air or regions prone to hurricanes—you need to bump that up to an annual inspection. That extra vigilance helps you catch accelerated corrosion and wear before they turn into major structural problems.

Beyond the big structural climbs, don't forget the simple stuff. We recommend quarterly ground-level visual checks. A quick walkthrough can spot immediate threats like vandalism, pest nests in your equipment cabinets, or overgrown vegetation that could become a fire hazard.

What Is the Biggest Challenge in Tower Maintenance?

Safety is and always will be the paramount concern. But from a pure logistics and operational standpoint, the single biggest headache is coordinating maintenance with co-located carriers.

This becomes a huge issue on shared infrastructure, like a municipal water tower hosting antennas for three or four different providers.

Imagine the primary structure needs major work, like a full repaint or structural reinforcements. To do the job right, every single carrier has to power down their equipment and have a crew physically remove their antennas. You're suddenly juggling multiple contracts, scheduling with several independent teams, and figuring out how to deploy temporary Cells on Wheels (COWs) to keep customers connected. It’s a logistical nightmare that demands serious planning and crystal-clear communication.

How Much Does Maintenance Typically Cost?

Tower maintenance costs are all over the map, driven by the tower’s height, its location, and exactly what work needs to be done. A simple ground audit might only set you back a few hundred dollars. On the other hand, a full climbing inspection that requires a certified crew and specialized gear will easily run into the thousands.

Where the budget really gets hammered is on emergency repairs. A surprise middle-of-the-night call-out can cost 3-5 times more than the same job done during a scheduled visit, thanks to rush mobilization fees and overtime labor.

The smartest way to manage your budget is to get ahead of the problems. By shifting your focus—and your funds—toward a proactive, preventative maintenance program, you drastically cut down on those expensive emergency calls. It’s a direct investment in better network uptime and a longer lifespan for your assets.

At Southern Tier Resources, we build and maintain the infrastructure that keeps your network performing at its peak. Our expert crews are equipped to handle everything from routine TIA inspections to the most complex structural upgrades, ensuring your sites meet the highest standards for safety and reliability. Partner with us to develop a smarter, more resilient maintenance strategy.