Building a fiber optic network is a massive undertaking. It's not just about digging trenches or stringing cable; it’s a meticulous process that takes a network from a drawing on a screen to a live, high-speed backbone for communities and businesses. Get it right, and you've built a foundational asset. Get it wrong, and you’re looking at costly overruns and years of operational headaches.

The Blueprint for a Modern Fiber Network

Taking a fiber project from concept to a fully operational network is where the real work begins. This isn't just theory—it’s a practical guide for carriers, municipalities, and data center operators who need to get the job done right. We're going to walk through the entire lifecycle, from the first site survey to navigating the labyrinth of permits and engineering challenges.

This is what you'll walk away with:

- A Clear Project Roadmap: Understand how to manage every stage, from the initial design all the way through to final documentation.

- Smart Construction Choices: We'll compare aerial and underground construction methods so you can decide which makes the most sense for your project and budget.

- Technical Best Practices: Get into the nitty-gritty of proper fiber splicing, testing, and what it takes to bring the network online without a hitch.

- Setting Up for the Future: Learn why detailed as-built documents aren't just a final step but a critical tool for long-term maintenance and success.

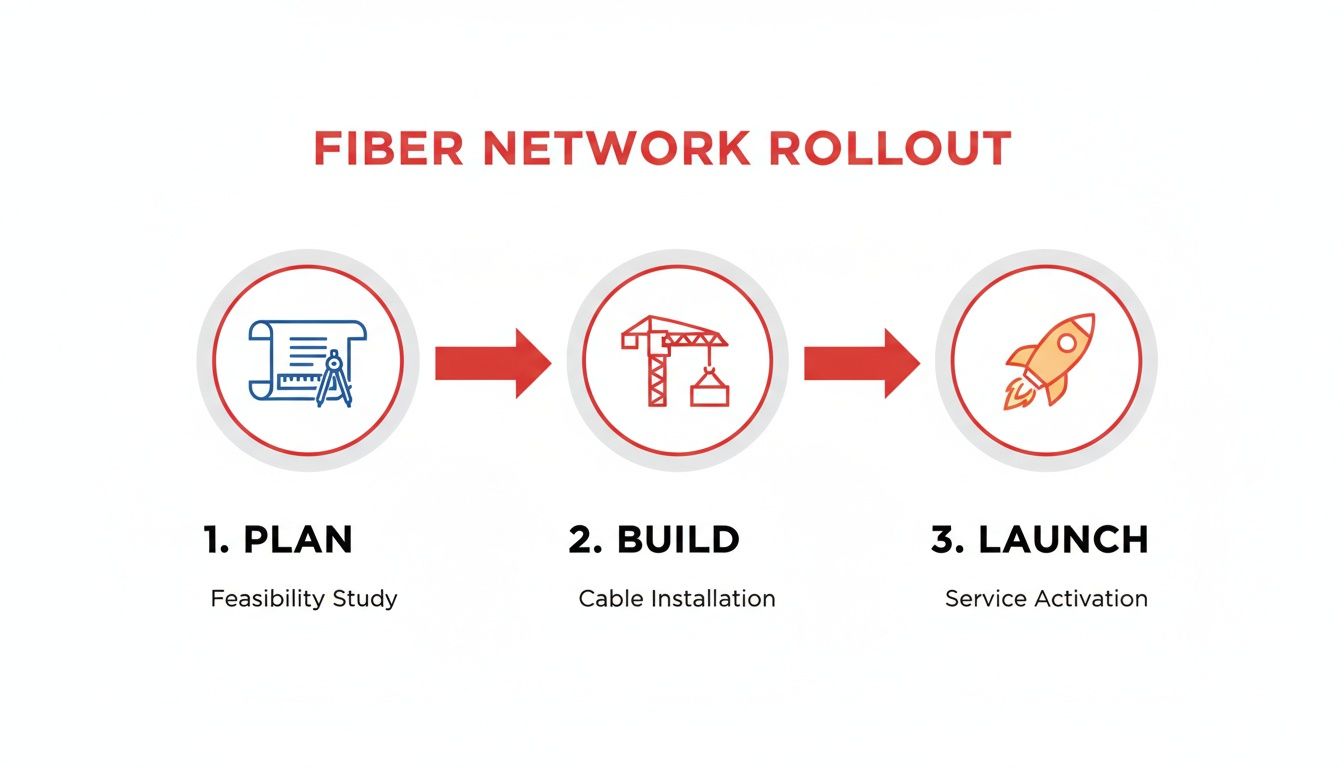

Think of the entire process in three core stages: planning, building, and launching.

This simple flow is our guide. A solid plan transitions into a well-executed build, which ultimately leads to a successful launch. Everything we'll cover is based on real-world experience, designed to help you deliver a high-performance network on time.

For a deeper dive into the specific components, our guide on intercommunication cable systems provides more granular detail.

Strategic Planning, Engineering, and Design

You don't build a great fiber network in the field. You build it on paper first. The fate of your project—its budget, timeline, and ultimate success—is decided long before the first shovel hits the ground. This is where the real work begins, turning a high-level goal into a detailed, buildable plan.

It all starts with getting your boots on the ground for site surveys and feasibility studies. This isn't just about tracing lines on Google Maps. It means walking every proposed route, documenting every pole, identifying every potential roadblock, and locating every existing utility. Trying to save time here is a classic rookie mistake that almost always leads to expensive change orders and brutal delays later on.

Choosing Your Network Architecture

With a clear picture of the physical landscape, your next big decision is the network's core architecture. This is a fundamental choice that dictates everything from equipment selection to the services you can offer.

You're generally looking at two main approaches:

- Point-to-Point (P2P): Think of this as a private, dedicated lane on the information highway. Each customer gets their own fiber strand running directly from your hub to their location. It's the gold standard for performance and security, making it perfect for businesses, data centers, or anyone with a high-stakes need for bandwidth.

- Gigabit Passive Optical Network (GPON): This is a point-to-multipoint system. A single fiber from your central office is split using passive optical splitters to serve multiple subscribers. It’s incredibly efficient and the go-to choice for most residential Fiber-to-the-Home (FTTH) rollouts because it keeps costs manageable.

The right choice depends on your business case. Are you serving a dense residential neighborhood or a business park? What do your service level agreements (SLAs) promise? A lot of the time, a hybrid model makes the most sense—running P2P to high-value commercial clients and using GPON for the surrounding homes.

The Paper Chase: Permits and Right-of-Way

Welcome to what is often the most frustrating and unpredictable part of any fiber build: securing permits and right-of-way (ROW) access. This is where your project can get bogged down in bureaucracy for months. You'll be dealing with a whole cast of characters—city planning departments, utility companies, state transportation authorities, and sometimes, individual property owners.

Your best weapon in these negotiations is a rock-solid, well-documented plan. Show up with detailed engineering drawings, environmental impact studies, and a clear construction schedule. It shows you’re a professional, not a fly-by-night operator, and it goes a long way toward speeding up approvals. Never underestimate the power of good local relationships.

This is also when you'll create a meticulous Bill of Materials (BOM). Your BOM needs to list every single component for the job—not just the fiber cable, but every splice enclosure, connector, and piece of mounting hardware. A precise BOM is absolutely critical for accurate cost forecasting and making sure your procurement team can get what you need, when you need it. To get a handle on all these moving parts, many project managers start adopting construction management software to keep things on track.

Designing for Tomorrow, Not Just Today

One of the most common and costly mistakes I see is designing a network that only meets today's demand. Bandwidth appetite is insatiable, fueled by everything from 8K streaming and cloud gaming to the explosion of IoT devices. The market reflects this, with the global fiber optic cable market surging at a 9.9% compound annual growth rate, projected to hit $7.6 billion by 2026. This isn't a trend; it's the new reality.

Building for the future means pulling more fiber than you need right now. Those extra, unused strands are called "dark fiber." While it adds a small percentage to your initial material cost, it gives you incredible scalability down the road. When a new customer signs up, you just have to light up a strand—no new trenching, no new permits, no new disruption.

The same logic applies to your hardware. Don’t box yourself in. Select equipment that has a clear upgrade path. For instance, choosing a GPON system that can be upgraded to next-gen standards like XG-PON or NG-PON2 ensures your network will stay competitive for years. This kind of foresight is what separates a simple construction project from a true long-term, revenue-generating asset.

Choosing Your Construction and Deployment Method

With your network design finalized, it's time to bring those plans into the real world. This is the stage where your decisions about construction directly shape the project's budget, timeline, and the ultimate resilience of your network. The big question you'll face right out of the gate is whether to build above ground (aerial) or bury your fiber underground.

There's no single "correct" answer here. Each approach comes with its own set of trade-offs, and the best choice is always dictated by the real-world conditions on the ground—local terrain, existing infrastructure, regulations, and of course, your budget. Getting this decision right is fundamental to a successful deployment.

Aerial Deployment: The Path of Least Resistance?

On the surface, stringing fiber optic cable along existing utility poles seems like the obvious choice. When the conditions are just right, it’s by far the fastest and most economical way to get your network built. If you have a clear run of poles with available space, you can completely sidestep the heavy costs and time sinks associated with excavation.

But here’s the catch: that "available space" is rarely as simple as it looks. This is where make-ready engineering comes into play, a critical phase that’s too often underestimated.

Make-ready is the detailed, pole-by-pole assessment to confirm that each structure can safely handle the new fiber. It’s a meticulous process:

- Structural analysis is needed to verify each pole’s integrity.

- Clearance checks must ensure safe distances from power lines, other comms cables, and roads.

- Existing attachments often need to be shuffled around just to carve out enough room for your cable.

It's not uncommon to find that poles need to be replaced entirely, which can throw a wrench in your budget and schedule. And let's not forget, working anywhere near energized power lines is incredibly hazardous and demands highly specialized crews who follow strict safety protocols.

Underground Construction: Built for the Long Haul

Placing fiber underground is all about building for longevity. It offers superior protection from ice storms, high winds, vehicle accidents, and vandalism, giving you a level of reliability that aerial simply can't match.

While the upfront cost is certainly higher, the drastically reduced maintenance and greater durability often lead to a lower total cost of ownership over the network's life.

When you go underground, you have a few methods to choose from, each suited for different scenarios.

- Trenching or Plowing: This is your classic, straightforward approach. Dig a trench, lay the conduit, and backfill. It's a proven method that works perfectly in open, rural areas or new construction zones where disrupting the ground isn't a major issue.

- Horizontal Directional Drilling (HDD): Got a busy highway, a river, or an environmentally sensitive area to cross? HDD is your solution. This trenchless technology lets crews drill a path right under the obstacle, leaving the surface almost completely undisturbed.

- Micro-Trenching: This has become a game-changer for dense urban builds. A specialized saw cuts a very narrow, shallow slot—think 1-2 inches wide—into asphalt or concrete. A micro-duct is dropped in, and the slot is sealed. It's incredibly fast and minimizes disruption to traffic and residents.

When you're weighing your options, context is everything. For a major road crossing in a city, HDD is a no-brainer. But for running fiber down a quiet residential street, micro-trenching keeps homeowners happy and gets the job done quickly, making it the preferred choice.

Comparing Fiber Optic Construction Methods

This table breaks down the key characteristics of aerial and underground fiber deployment to guide your project's decision-making process.

| Method | Typical Cost | Deployment Speed | Ideal Environment | Key Challenge |

|---|---|---|---|---|

| Aerial | Lower | Fastest | Areas with existing utility poles | Make-ready engineering, storm damage |

| Underground | Higher | Slower | Dense urban areas, new builds, high-reliability needs | Higher upfront cost, permitting complexity |

Ultimately, the best strategy is often a hybrid one, using the most appropriate method for each specific segment of your network route.

Selecting the Right FTTx Architecture

Beyond just placing the cable, you have to decide how you'll architect the final connection to your customers. This is the world of Fiber-to-the-X (FTTx), where the "X" is the endpoint.

Three architectures really dominate the field:

- Fiber-to-the-Home (FTTH): This is the gold standard for residential service. It means running a dedicated fiber line straight to each house, delivering the absolute best speeds and performance possible.

- Fiber-to-the-Building (FTTB): A very practical approach for apartment complexes and office buildings. Here, you run fiber to a central communications room in the building and then use existing ethernet or copper wiring to reach individual units.

- Fiber-to-the-Curb/Node (FTTC/N): With this model, fiber runs to a shared cabinet that serves a whole neighborhood. The last leg of the journey to each home is completed over the existing copper phone lines or coaxial cable.

Your choice here should directly reflect your business goals. If you’re an ISP aiming to deliver premium gigabit service, you're going to invest in FTTH. If you're upgrading an existing apartment building, FTTB is a much more pragmatic and cost-effective path. You can also explore the specifics of the different types of laid cables to get a better handle on the physical components.

The push for these deployments is massive. In 2024 alone, U.S. fiber builds reached a record 10.3 million new homes, with projections showing over 60% of all households will have fiber access by 2025. This boom is being fueled by $42.45 billion in federal BEAD program funding finally hitting shovel-ready projects. It’s clear that fiber is on track to become the dominant broadband platform by 2028. You can dive deeper into these trends by reading the full forecast on global optical fiber preform trends.

Mastering Splicing, Testing, and Network Activation

Getting the physical cable in the ground or on the poles is a huge accomplishment, but the real performance of your network comes down to the microscopic connections made in the field. This is where precision is everything. A single poorly executed splice or an overlooked test can create performance bottlenecks that are incredibly difficult and expensive to track down after the network goes live.

This final technical phase is all about ensuring every connection is as close to perfect as possible.

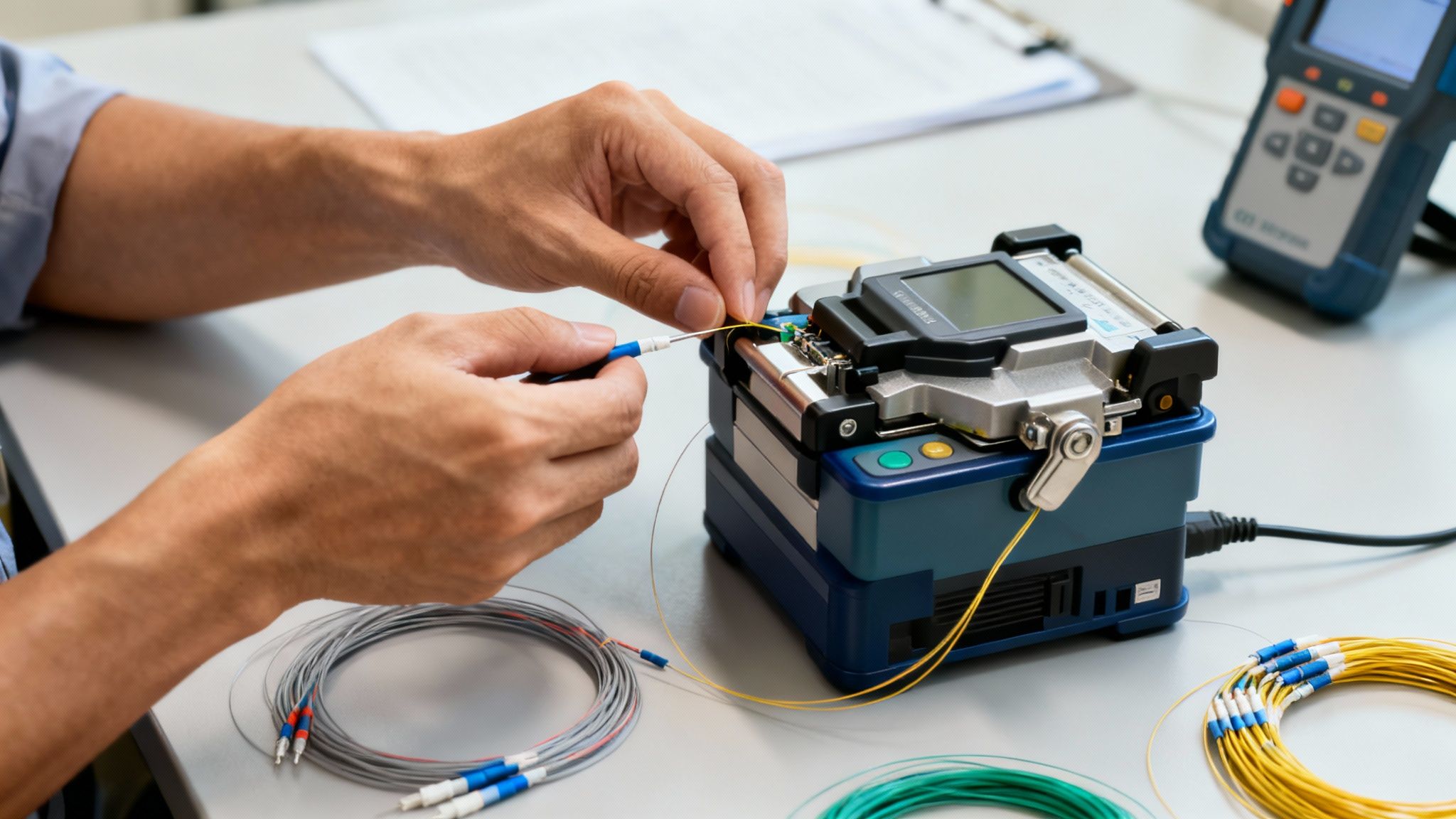

We call the art and science of joining two fiber optic strands splicing. The goal is always the same: create a seamless connection with the absolute minimum signal loss, which we measure in decibels (dB). Even a tiny imperfection—a speck of dust, a slight misalignment—can degrade the signal and impact your customers.

The Craft of Fiber Splicing

In any professional network build, you’ll encounter two primary methods for splicing fibers. Each has its place, but one is clearly the go-to for creating the permanent, core infrastructure of a network.

Fusion Splicing: This is the undisputed gold standard. A specialized machine, called a fusion splicer, perfectly aligns the two fiber ends and then uses an electric arc to literally melt them into a single, continuous piece of glass. The result is an incredibly strong connection with almost negligible loss, typically less than 0.05 dB. This is the only acceptable method for backbone cables and long-haul links where signal integrity is non-negotiable.

Mechanical Splicing: This method uses a small, self-contained device to align the fibers and hold them in place with a special index-matching gel. It’s faster and the equipment is cheaper, making it a decent option for temporary repairs or in tight spots where a fusion splicer isn't practical. The trade-off is a much higher signal loss (often 0.3 dB or more) and lower long-term reliability.

For anyone serious about building a high-performance network, investing in quality fusion splicers and, more importantly, skilled technicians is not an area to cut corners. That seemingly small loss from a mechanical splice can compound across a network, degrading the experience for everyone on it.

Rigorous Testing Protocols

Once the splices are done, you can't just assume everything is working. You have to prove it with data. A comprehensive testing protocol is your quality control, validating that the network was built exactly to its design specifications.

This isn’t about just shining a light down the fiber and seeing if it comes out the other end. It’s about quantifying the performance of every single strand with specialized tools.

- Optical Loss Test Set (OLTS): Think of an OLTS as the final exam for a fiber link. It provides a highly accurate, end-to-end measurement of the total signal loss (attenuation), giving you a clear pass/fail verdict against your design's "loss budget."

- Optical Time Domain Reflectometer (OTDR): An OTDR is more like a radar for your fiber. It sends a pulse of light down the cable and measures the reflections that bounce back, creating a graphical "trace" of the entire link. This lets you pinpoint the exact location and severity of every splice, connector, and even sharp bends that might be causing loss.

A professional closeout package isn't complete without both OLTS and OTDR test results for every single fiber strand. The OLTS certifies the link's overall performance, while the OTDR provides a detailed "birth certificate" that is invaluable for future troubleshooting. If a backhoe ever damages your cable, that original OTDR trace will tell your repair crew exactly where to dig.

Network Turn-Up and Commissioning

With all splices completed and every fiber tested, you're ready to light it up. Network activation is the process of connecting the active electronics—the switches, routers, and optical transmitters that will carry live data. To get a better handle on this, learn more about the crucial role of fiber optic transmitters and see how these components fit into the big picture.

The commissioning process involves a systematic check of all systems. Technicians configure the equipment, verify light levels are within spec at both the transmitting and receiving ends, and run data traffic tests to ensure the network is stable. This methodical approach guarantees a smooth transition from a construction project to a live, service-ready network that will operate reliably for years to come.

Finalizing Documentation and Project Closeout

A fiber optic network build isn't over when the last splice is cool. The project is only truly complete once every single asset—every cable, every splice, every enclosure—is meticulously documented. It's tempting to rush this final step, but that's a costly mistake I've seen create massive operational headaches for years to come.

Think of it this way: comprehensive documentation is the only thing that transforms a complex web of glass and hardware into a manageable, long-term asset. Without it, your operations team is flying blind every time a backhoe goes rogue or a customer needs an upgrade.

Creating the Definitive As-Built Package

The cornerstone of your closeout is the as-built documentation. These aren’t just copies of the original engineering plans. As-builts are the final, verified records of exactly what was installed in the field, reflecting every minor deviation and on-the-fly adjustment that inevitably happens during construction. They are the ground truth.

Modern network documentation has moved far beyond static PDFs or, worse, paper maps filed away in a cabinet. The industry standard is Geographic Information System (GIS) mapping. A well-executed GIS platform creates a dynamic, layered, and searchable "digital twin" of your entire network.

Imagine a field technician being able to pull up a map on their tablet and see:

- The exact GPS coordinates of a splice enclosure.

- Which specific fiber strands are connected to which ports.

- The depth and route of the underground conduit they're standing over.

- The original OTDR test results for that specific fiber link, pulled up with a single click.

That level of detail is invaluable. When an outage hits at 2 AM, your team can pinpoint the likely failure point from a screen instead of wasting precious hours physically tracing cables in the dark.

What Goes into a Final Closeout Package

Handing over a complete and professional closeout package is what truly marks the end of a project. It’s the final deliverable that arms the network owner with everything they need for decades of effective management. I like to think of it as the network's official birth certificate and owner's manual, all rolled into one.

A truly complete closeout package leaves no room for ambiguity. It is the single source of truth that will be referenced for every maintenance ticket, service upgrade, and future expansion for the next 20+ years. Getting it right today saves immense time and money tomorrow.

This final handoff should always bundle together several critical components.

Key Deliverables for Project Closeout

- Certified Test Results: This includes the final OLTS and OTDR reports for every single fiber strand, proving the network meets or exceeds all performance specs. No exceptions.

- Complete As-Built Drawings: Both digital GIS files and printable map formats showing the precise location of all cables, conduits, enclosures, and hardware.

- Splicing Documentation: Detailed splice matrices or charts that map every individual fiber connection within each splice point. This is non-negotiable for troubleshooting.

- Material and Equipment Lists: A final inventory of all installed components, right down to manufacturer names, model numbers, and serial numbers for active equipment.

- Permits and Lien Waivers: All approved permits from the relevant authorities and, crucially, signed lien waivers from all contractors and subs to ensure a clean transfer of ownership.

This disciplined record-keeping is what protects the investment in the assets that form your network's intelligent backbone. This backbone includes critical hardware like fiber optic network switches, with global sales projected to hit 22 million units by 2025. This growth, largely driven by data centers fueling cloud and AI workloads, is pushing the market from $703 million in 2025 to $1.12 billion by 2034. You can learn more about how this trend impacts network rollouts from research on the global fiber optic network switch market.

Managing Costs, Risks, and Vendor Partnerships

Building a fiber optic network is a major capital investment. Your long-term return hinges on how well you manage the budget, the risks, and the relationships you build from day one. Solid financial planning is so much more than a simple cost-per-foot calculation; it’s about anticipating the hidden expenses that can completely derail a project and having a game plan to deal with them.

The things that kill a budget are almost always the surprises. For example, finding out that 20% of the utility poles in your aerial route need replacing during make-ready can suddenly add six figures to your costs. It happens. Likewise, unexpected permit delays from a single municipality can put construction on hold for months, leading to expensive crew downtime and missed deadlines for turning up customers.

Proactive Financial and Safety Management

To protect your investment, you absolutely have to build a budget with a healthy contingency. A standard 10-15% contingency fund is a decent starting point, but let your initial site surveys guide you. If your path involves multiple railway crossings or cuts through environmentally sensitive areas, a higher contingency isn't just a good idea—it's just smart business.

Beyond the financial risks, physical safety is paramount. Let's be clear: construction zones are dangerous. A single serious accident can stop work indefinitely and create massive liability. A non-negotiable, rigorously enforced safety program is the only way to manage this risk.

This program isn't just a binder on a shelf. It must include:

- Daily Job Safety Analyses (JSAs): Every morning, crews must meet to identify and talk through the specific hazards for that day's work. No exceptions.

- Strict Utility Locate Protocols: Always use "call before you dig" services. Hitting a gas or power line is a catastrophic failure.

- Certified Traffic Control Plans: Any work near roadways requires a professional plan to protect both your crews and the public.

Selecting the Right Infrastructure Partners

You can have a perfect design and a rock-solid budget, but your project's success ultimately comes down to the people doing the work. Not all contractors are created equal, and choosing the right one is one of the most critical decisions you'll make.

When you're vetting potential partners, look for a proven track record in fiber deployment specifically, not just general construction. Ask for case studies. Talk to their references from projects of a similar scale. Demand proof of their safety record. A low bid from an inexperienced contractor often ends up being the most expensive choice you can make.

The ideal collaborator is more than just a contractor; they are a turnkey infrastructure partner. This means they can manage the entire project lifecycle—from permitting and engineering to construction, splicing, testing, and final documentation—under a single, accountable point of contact.

How you structure your agreements is just as important as who you pick. Your contracts need to clearly define the scope of work, set firm milestones with payment schedules tied to them, and spell out the penalties for missed deadlines. But more importantly, they should align incentives. Consider structuring a bonus for early completion or for coming in under budget. This makes the contractor a true stakeholder in your success, turning a simple transaction into a genuine partnership focused on the shared goal of getting a high-performance network built on time and on budget.

Common Questions About Fiber Network Construction

Even with the most detailed blueprint in hand, building a fiber optic network always brings up questions. It's just the nature of such a complex undertaking. Over the years, we've heard just about everything from project managers, engineers, and city planners.

Here are some of the most common questions we get, along with some straight-from-the-field answers. Getting a handle on these issues early can save you a world of headaches—and budget—down the line.

What Is the Biggest Unexpected Challenge in a Typical Fiber Build?

It almost always comes down to navigating permits and right-of-way (ROW) access. People tend to focus on the physical construction, but the bureaucratic side of things can stop a project cold for weeks, sometimes months.

Getting tangled in red tape with municipalities or utility companies is a classic, costly delay. That's why we always push for engaging with these groups as early as possible, well into the design phase. It also pays to have a partner who already knows the local regulatory landscape.

Another classic "surprise" is hitting unmapped underground utilities during excavation. This reinforces just how crucial a thorough site survey is and why "call before you dig" isn't just a suggestion—it's a project-saver.

The most underestimated challenge is often the human element. You're constantly negotiating with stakeholders, from city officials to private landowners. A project’s momentum can live or die based on how well you manage those relationships and how clearly you communicate.

How Do I Choose Between Aerial and Underground Fiber Installation?

This is a classic trade-off between cost, your environment, and long-term maintenance realities.

Aerial deployment is typically faster and comes with a lower price tag, if you have existing utility poles with available space. This makes it a great fit for many suburban and rural builds. The big downside? It’s much more exposed to severe weather, falling tree limbs, and other physical damage.

Underground fiber, on the other hand, is the gold standard for protection and reliability. It's the go-to for dense urban cores, new housing developments, and areas that get hit with extreme weather. Of course, that security comes at a higher initial cost and a slower installation timeline.

In reality, most large-scale projects end up using a hybrid approach, strategically running fiber overhead where it makes sense and burying it where it's needed most.

How Long Does It Typically Take to Build a Fiber Network?

The timeline can swing wildly depending on the project's scale. A small network for a business campus might be wrapped up in a few months. A city-wide Fiber-to-the-Home (FTTH) project? You could be looking at several years from start to finish.

A project timeline generally breaks down into a few key stages:

- Planning and Design: 3-6 months

- Permitting and Make-Ready: 6-12+ months (This is very often the longest and most unpredictable phase)

- Construction: 12-24+ months, which scales with the size of the network

- Network Turn-Up: 1-3 months

Things like population density, local geography, and just how quickly local authorities move all have a massive impact on the final schedule.

Successfully navigating these challenges isn't about having a good plan; it's about having a partner with the field experience to execute it. Southern Tier Resources provides complete engineering, construction, and maintenance for complex fiber optic networks, ensuring your project is done right and on time.

Learn how our turnkey solutions can bring your network to life by visiting us at southerntierresources.com.