When you hear the term outside fiber plant (OSP), think of it as the nervous system of our modern digital world. It's the entire physical network—all the cables, conduits, poles, and hardware—that carries high-speed data from a central hub right to a home or business.

It’s a lot like a city’s water main system. Just as pipes carry water from a treatment plant to every faucet, the OSP creates a durable, high-capacity pathway for light signals carrying a torrent of information. This network is the literal foundation of modern communication.

The Foundation of Modern Connectivity

The name says it all: an outside fiber plant is everything that lives "outside" the walls of the central telecom office and the subscriber's building. It's the silent, unseen workhorse powering our digital lives, connecting entire communities, businesses, and the cell towers we rely on. Without a solid OSP, things like high-speed internet, Netflix binges, and 5G simply wouldn't exist.

But this infrastructure is so much more than just the fiber optic cable itself. It's a complete, engineered system designed to protect those fragile glass strands from the elements across vast distances. Every single component is built for toughness and long-term performance, making sure data can fly reliably at the speed of light for decades.

Why OSP is So Critical

You really can't overstate the importance of a well-designed outside fiber plant. It’s the essential layer that carriers and internet service providers build their businesses on. Getting the OSP right from the start delivers some serious advantages that define what modern connectivity can be:

- Immense Bandwidth Capacity: Fiber optic cables can handle vastly more data than old-school copper wires. This isn't just a small improvement; it's a quantum leap that's necessary to keep up with today's data appetite.

- Future-Proof Scalability: Here’s the beautiful part. A well-built fiber network can handle tomorrow's speed demands without digging up the streets again. You just upgrade the electronics at each end of the cable.

- Unmatched Reliability: Unlike copper, fiber is completely immune to electromagnetic interference (think power lines or lightning). It's also far more resistant to corrosion and weather, which means a much more stable and dependable connection.

- Enabling New Technologies: Advanced services like 5G, the Internet of Things (IoT), and high-definition cloud gaming are incredibly demanding. They need the massive capacity and near-instantaneous response times that only a dense fiber network can deliver.

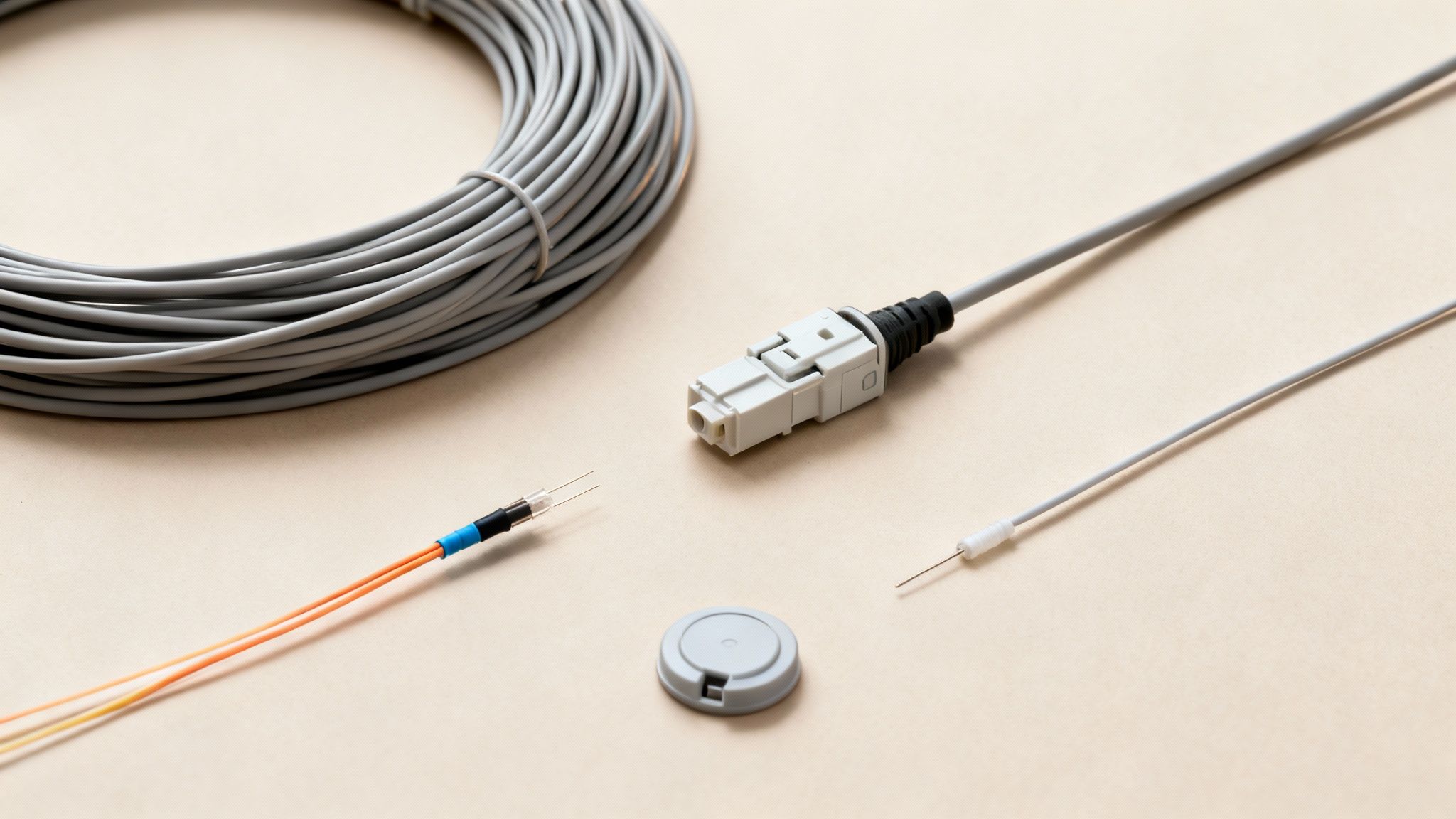

To give you a quick reference, here's a look at the core parts of an OSP network.

Key Elements of an Outside Fiber Plant Network

This table breaks down the primary components you'll find in any OSP network, giving you an at-a-glance summary of what each part does.

| Component | Function in the Network |

|---|---|

| Feeder Cable | The high-capacity "main artery" that runs from the central office to a specific neighborhood or service area. |

| Distribution Cable | Taps off the feeder cable and runs down streets or through subdivisions, bringing the network closer to subscribers. |

| Drop Cable | The final, smaller cable that connects an individual home or business directly to the distribution network. |

| Splice Point | An enclosure where individual fiber strands from different cables are fused together to create a continuous path. |

| Handhole/Manhole | Underground vaults that provide access to cables and splice points for installation, maintenance, and repairs. |

| Conduit/Ducts | The protective piping, either buried or aerial, that houses and safeguards the fiber optic cables from damage. |

Each element plays a crucial role in creating a resilient and high-performing network that can stand the test of time.

An outside fiber plant is not just an asset; it's a long-term investment in a community's economic and technological future. It lays the groundwork for decades of innovation and growth.

The demand for this critical infrastructure is absolutely exploding. The global fiber optics market, which is the engine behind OSP, is projected to climb from USD 6.6 billion to USD 14.7 billion by 2033. This growth is largely fueled by the massive, ongoing rollout of 5G networks. If you're interested, you can explore more data on this market growth to see just how big this expansion really is.

Understanding the Core Components of OSP

Think of an outside fiber plant (OSP) like a city's water supply system. You have massive water mains leaving the treatment plant, smaller pipes branching off to serve neighborhoods, and finally, a single line running to each house. Every piece of that system is engineered for its specific job, and they all have to work together perfectly to deliver water where it's needed.

An OSP works on the same principle. To really get a handle on how this massive infrastructure operates, we need to break it down into its essential parts. From the super-high-capacity cables leaving the central office to the final connection at a customer's building, every component plays a critical role.

The Fiber Optic Cable Hierarchy

Not all fiber is the same. In the field, we categorize cables based on where they fit into the network's overall design. This tiered structure is the key to delivering bandwidth efficiently from the network's core right to the end-user.

- Feeder Cables: These are the interstate highways of the fiber world. Feeder cables are packed with a high count of fiber strands and are built to carry huge volumes of data from a central office or main hub out toward specific service areas.

- Distribution Cables: Now we're on the main streets of the neighborhood. Distribution cables tap into the feeder lines at strategic points (often inside a cabinet called a Fiber Distribution Hub) and run along local roads, getting connectivity much closer to homes and businesses.

- Drop Cables: This is the final driveway. A drop cable is the last piece of the puzzle, a smaller cable that runs from the distribution line on the street directly to an individual home, office, or cell tower, completing the data's journey.

This layered approach is just plain logical. It lets network operators manage their capacity from the top down, making sure the backbone can always support the countless connections branching off it.

Protective Pathways: Ducts and Conduits

Those delicate glass fibers at the heart of the cable need serious protection from the elements. That's where ducts and conduits come in—they act as the network's armored shell.

A conduit system is simply a network of pipes, usually made from durable materials like PVC or HDPE, that gives the fiber cables a safe home underground. This pathway is a shield against everything from shifting soil and moisture to accidental damage from a backhoe.

A well-planned conduit system is one of the smartest long-term investments you can make in an OSP project. It makes future upgrades incredibly simple, letting you pull or "jet" new cables through existing pipes without having to dig up the ground all over again.

This concept of "future-proofing" is a game-changer. Having the ability to add more capacity down the road for a fraction of the initial cost gives network owners a massive operational advantage. If you want a closer look at the gear involved, our guide on essential networking components and their functions is a great resource.

Aerial Versus Buried Plant Deployment

One of the first big decisions in any OSP project is whether to go up or down: hang the fiber on poles or bury it in the ground. Each method has its own set of trade-offs, and the right choice usually comes down to cost, what's already there, and local rules.

Comparison of Deployment Methods

| Feature | Aerial Deployment | Buried Deployment |

|---|---|---|

| Installation Cost | Generally lower, a big plus if you can use existing utility poles. | Significantly higher due to trenching, boring, and restoration costs. |

| Installation Speed | Faster. You avoid most of the slow, complex work of digging. | Slower. It requires careful planning, more permits, and heavy construction. |

| Aesthetics | Can be an eyesore for some, with visible cables hanging from poles. | Completely invisible once installed, which is great for property values. |

| Vulnerability | Exposed to ice storms, high winds, falling trees, and car accidents. | Extremely well-protected from weather and most surface-level threats. |

| Maintenance | Repairs are typically easier and cheaper since everything is accessible. | Finding and fixing a problem can be difficult and expensive, requiring excavation. |

While a buried network offers incredible protection and a longer lifespan, the upfront cost can be a deal-breaker, especially in rocky areas or crowded cities. Aerial is often the more practical, cost-effective choice. In reality, most networks are a hybrid, with some sections buried and others running on poles where it makes the most sense.

Access and Connection Points

You can't just bury fiber and forget about it. Technicians need designated spots to access the network for connections, maintenance, and troubleshooting. These access points are placed strategically to house the hardware that brings it all together.

- Vaults and Handholes: These are underground enclosures. They can be as large as a manhole (vaults) or as small as a shoebox (handholes). They act as subterranean junction boxes, giving technicians a safe, dry place to work on conduits and splice points.

- Splice Closures: A splice closure is basically a rugged, weatherproof container. Its only job is to protect the delicate points where two fiber strands have been permanently fused together. You'll see them hanging from aerial lines or tucked away inside a handhole, keeping those critical connections safe from the elements.

These might not be the most glamorous parts of the network, but they are the unsung heroes. Without these access points and protective cases, managing and expanding a fiber network over its long life would be next to impossible.

Engineering a Resilient Fiber Network

Long before the first shovel ever breaks ground, the real success of a fiber network is decided on the drawing board. This is the engineering phase, where foresight and strategy transform a simple idea into a detailed blueprint for a robust, future-proof network. It’s the difference between laying a simple dirt path and architecting an interstate highway system built for growth.

This crucial planning stage is about so much more than just connecting two points. It's a meticulous process of route planning, capacity forecasting, and architectural design. The goal is a network that’s not only cost-effective to build today but also resilient and scalable enough to meet demands for decades to come.

Charting the Course with Route Planning

First things first, you have to figure out the most practical path for the fiber to travel. This process, known as route planning, is way more involved than just drawing a line on a map. Engineers dive deep, conducting feasibility studies to analyze every foot of the proposed route and weigh all the variables to find the absolute best path forward.

- Geographic and Environmental Hurdles: Is the ground solid rock, demanding expensive drilling? Does the route have to cross a river, a major highway, or environmentally sensitive wetlands? Every one of these obstacles adds a layer of complexity and cost that has to be factored in.

- Existing Infrastructure: Can we use existing utility poles for an aerial build and save a ton on construction? Is there any underground conduit already in place that we can lease? Finding these opportunities is a massive win for the project budget.

- Right-of-Way (ROW) Access: Securing the legal right to build across public or private land can be one of the biggest time-sinks in any project. A viable route has to have a clear and achievable path for getting all the necessary permits and permissions.

This in-depth analysis makes sure the chosen route isn't just the shortest, but the most buildable and financially sound one.

Designing for Tomorrow's Demand

One of the most common mistakes people make is planning only for today's needs. A truly resilient outside fiber plant is engineered with scalability baked right in. This means thinking about future growth and building in the capacity to handle it, so you’re not forced into disruptive and expensive construction projects down the road.

Capacity planning involves forecasting subscriber growth, exploding data usage, and the potential for new services over the network’s 20- to 30-year lifespan. Engineers will almost always specify cables with far more fibers than are needed on day one. These "dark fibers"—the unused strands in the cable—are an incredibly valuable asset, ready to be lit up as soon as demand grows.

A common best practice is to build a network with 50% or more spare fiber capacity. The extra material cost upfront is tiny compared to the enormous expense of trenching and installing a second cable years later.

This forward-thinking approach means the network can evolve right alongside technology. When it's time for a speed boost, operators can simply upgrade the electronics at each end to increase bandwidth exponentially without ever having to touch the outside fiber plant itself.

Building in Reliability with Network Topology

Finally, engineers have to decide on the network's fundamental architecture, or topology. This design choice dictates how everything is interconnected and is the single biggest factor in the network's reliability and its ability to withstand an outage.

Two of the most common topologies you'll see in an outside fiber plant are:

- Star Topology: This is the classic hub-and-spoke model. Every end point connects directly back to a central hub. It's pretty straightforward to design and manage, but its Achilles' heel is that single point of failure—if the central hub goes down, every connected location loses service.

- Ring Topology: In this setup, all the nodes are connected in a continuous loop. Data can travel in two different directions, which creates a self-healing network. If a backhoe cuts a cable at one point in the ring, traffic is automatically rerouted the other way, often without anyone noticing a service interruption.

For mission-critical infrastructure, engineers will often implement a redundant ring topology to guarantee the highest possible uptime. While it's more complex and costs more to build, this approach creates the kind of robust, always-on connectivity that modern businesses and communities absolutely depend on. For a deeper look into this process, learn more about our approach to expert telecom engineering and how we design for resilience.

Navigating OSP Construction Methods

Once the engineering blueprints are finalized, it's time to break ground and bring the outside fiber plant into the physical world. This is where the paper plans meet heavy machinery, skilled crews, and the unpredictable nature of fieldwork. The construction methods we choose are dictated by the environment, the budget, and the long-term vision for the network.

Every OSP project falls into one of two categories: Greenfield or Brownfield. Knowing the difference is fundamental to understanding the scope of the work ahead.

- Greenfield Projects: Think of this as building a new neighborhood on a completely empty plot of land. You're deploying fiber where no infrastructure exists. It’s a blank slate, which is great for optimizing the design, but it means everything—ducts, handholes, vaults—has to be built from scratch.

- Brownfield Projects: This is more like a home renovation. You're working within an existing infrastructure, maybe pulling new, higher-capacity fiber through old conduits or adding cables to already crowded utility poles. The core structure is there, but navigating its limitations presents its own unique set of challenges.

This initial distinction shapes every subsequent decision, from the equipment on-site to the project timeline itself.

Buried Construction Techniques

Placing fiber optic cable underground is the gold standard for protecting a network. It shields the delicate glass strands from severe weather, vehicle accidents, and vandalism, ensuring maximum reliability. But getting that cable into the ground is a specialized job, and the right technique depends entirely on the terrain.

Below is a quick comparison of the most common methods for installing buried fiber. Each has its place, and choosing the right one is critical for both efficiency and budget.

Comparison of OSP Construction Methods

| Method | Best For | Pros | Cons |

|---|---|---|---|

| Directional Boring (HDD) | Crossing roads, rivers, and environmentally sensitive areas where open-cut trenches are not an option. | Minimal surface disruption; precise control over the bore path. | Slower and more expensive than plowing; requires highly skilled operators. |

| Plowing | Open, rural areas with soft soil and few existing underground utilities. | Extremely fast and cost-effective; installs cable or conduit in a single pass. | Not suitable for rocky soil or congested urban areas; can be more disruptive to the surface. |

| Microtrenching | Dense urban and suburban environments with paved surfaces like roads and sidewalks. | Very little disruption to traffic and surroundings; quick installation and backfill. | Shallow depth offers less protection; not ideal for areas with frequent road work. |

As you can see, there's no single "best" method. The decision is a strategic one, balancing speed, cost, and the long-term integrity of the network.

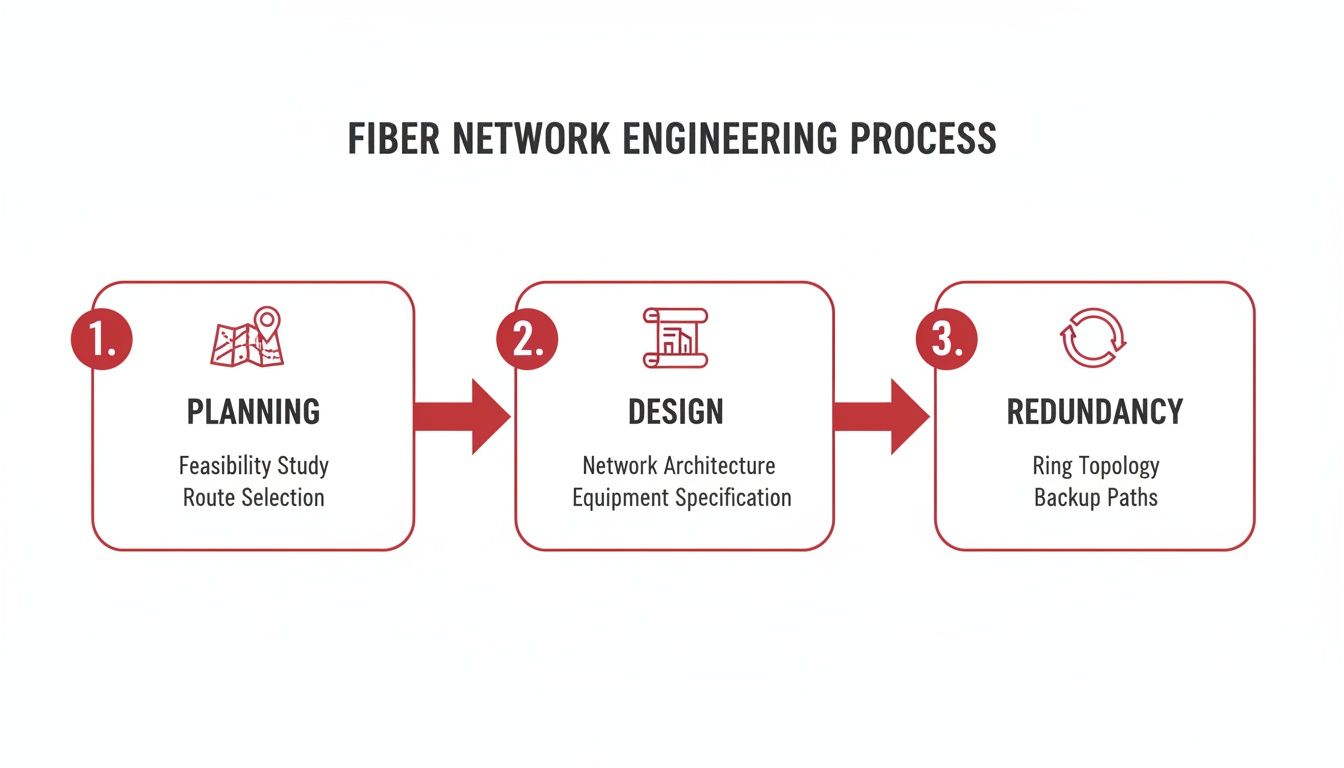

The diagram below gives a high-level view of how these complex construction phases fit into the overall engineering process. It all starts with meticulous planning.

This visual really drives home the point: successful construction is impossible without a solid foundation in planning and design, ensuring that resilience is baked in from day one.

Aerial Installations And Make-Ready Work

When burying fiber just isn't practical or cost-effective, we look to the sky. Attaching fiber optic cables to existing utility poles is a common and often faster alternative. But it's not as simple as just stringing a new line. First, you have to complete a critical process known as make-ready construction.

Make-ready is the essential, non-negotiable work required to prepare a utility pole for a new fiber attachment. This often involves repositioning existing cables to create space, ensuring safe clearance from power lines, and sometimes even replacing an old or overloaded pole entirely.

Attempting to cut corners on make-ready is a recipe for serious problems, from safety violations and hefty fines from pole owners to future network failures. It's a foundational step that has to be done right. To get a better sense of this crucial preparatory work, you can learn more about the importance of groundwork in telecom projects.

This entire field is seeing a massive influx of investment. The optical fiber connectivity market recently hit USD 3.3 billion and is expected to climb at a 9.3% compound annual growth rate through 2034. This boom is fueled by the relentless demand for Fiber to the Home (FTTH) and the ongoing 5G rollout, both of which depend on a robust and expansive outside fiber plant.

Managing Permits, Regulations, and Safety

Building a fiber network isn't just about digging trenches and stringing cable. It’s a delicate dance with public agencies, utility owners, and safety regulations. Honestly, getting the permits and approvals in place is often a bigger challenge than the physical construction itself. Get this part wrong, and you're looking at serious delays, steep fines, and even dangerous accidents.

Everything starts with the fundamental legal right to build in the first place. We call this right-of-way (ROW), and it's the official permission slip to place your infrastructure on public or private property. Getting ROW access can involve long, drawn-out negotiations with city governments, utility companies, and even individual landowners. It's easily one of the most time-consuming hurdles in any fiber deployment.

Navigating the Permitting Labyrinth

Once you've secured the right-of-way, the real paper chase begins. You'll need a stack of permits from local, state, and sometimes federal authorities before you can break ground. Each permit is a checkpoint, ensuring your work meets specific standards for safety and public good.

Here are a few of the usual suspects you'll encounter on your permitting journey:

- Encroachment Permits: Planning to work on or under public roads, sidewalks, or parks? You'll need one of these.

- Pole Attachment Agreements: For any aerial fiber, you have to get a legal contract with the pole owners (usually the power or phone company). This agreement spells out everything from where you can attach your cable to how much you'll pay in annual rent.

- Environmental Permits: If your route comes anywhere near sensitive areas like wetlands or protected wildlife habitats, you’ll need special clearance to prove you’re not causing ecological harm.

This is where having a team that's been through it before really makes a difference. A single missed detail on an application can stop a multi-million dollar project dead in its tracks.

Putting Safety First—For Everyone

With the paperwork finally in order, all eyes turn to safety on the job site. This isn't just a box to check; it's the most important responsibility we have.

Before a single shovel hits the dirt, there's a critical, legally-mandated first step: calling 811. This "call before you dig" service alerts all local utilities, who then come out and mark the locations of their buried gas, water, and electric lines. Hitting one of those isn't just an expensive mistake—it can be deadly.

Beyond what's underground, a solid safety plan is essential to protect the public and the crew. This means setting up proper traffic control with cones, signs, and flaggers to guide people safely around the work area.

And for the crew itself, having the right Personal Protective Equipment (PPE) is non-negotiable. We're talking hard hats, high-visibility vests, safety glasses—the full works. Following these rules isn't just about compliance; it’s about creating a safety-first culture that's at the core of every successful fiber build.

Ensuring Long-Term Network Performance

The job isn’t over once the last fiber is spliced. An outside fiber plant is a long-term asset, and protecting that investment demands a disciplined approach to testing, maintenance, and overall lifecycle management.

These ongoing efforts are what separate a network that simply works from one that performs reliably for decades.

The very first step after construction wraps up is testing and certification. This is far more than a simple "lights on" check; it's a meticulous process to validate the quality of every single strand of glass.

Validating Performance with Precision Testing

Field technicians use highly specialized equipment to "sweep" the fibers, measuring signal loss (attenuation), reflections, and the overall integrity of the pathway. The workhorse for this job is the Optical Time-Domain Reflectometer (OTDR).

An OTDR sends a quick pulse of light down the fiber and analyzes the light that scatters or reflects back. This allows a technician to pinpoint the exact location and severity of any issue—a bad splice, a sharp bend, or a faulty connector—with remarkable accuracy. This process creates a baseline "birth certificate" for the network, a vital reference point for any future troubleshooting.

Proactive and Reactive Maintenance Strategies

With a certified, high-performing network in place, the focus shifts to upkeep. Maintenance for an outside fiber plant typically falls into two categories, both equally important for keeping the network online.

- Proactive Maintenance: These are the scheduled activities designed to catch problems before they cause an outage. Think of it as preventative care—inspecting splice enclosures for water intrusion, trimming trees near aerial lines, or checking the integrity of conduits.

- Reactive Maintenance: This is the emergency response. When a backhoe digs in the wrong place or a storm takes down a utility pole, reactive maintenance crews are the first responders tasked with locating the fault, making repairs, and getting services back online as quickly as possible.

A strong proactive maintenance program significantly reduces the need for costly and disruptive reactive repairs. By identifying potential weak points early, operators can maintain a higher level of service continuity and customer satisfaction.

Lifecycle Management for Future Growth

Finally, lifecycle management is about taking the long view. It involves keeping meticulous and current documentation—often called "as-builts"—that accurately maps every cable, splice point, and conduit in the ground or on the poles. These records are absolutely essential for planning future expansions and speeding up repairs.

This kind of long-term planning has never been more critical. The explosion in demand from AI and hyperscale data centers has turned outside fiber plant into a massive growth engine. The overall fiber optics market hit USD 98.65 billion in a single year and is projected to reach USD 171.70 billion by 2032.

Ensuring network durability is a priority, supported by programs like the Funding for Sustainable Digital Infrastructure, which champions responsible and resilient deployments. By combining rigorous testing, diligent maintenance, and smart lifecycle management, a network can not only meet today's demands but also adapt to whatever comes next.

Your Top Outside Fiber Plant Questions, Answered

You’ve got the basics down, but what does an outside fiber plant project really look like on the ground? Let's get into the practical questions we hear all the time from clients and partners.

These are the real-world issues that can make or break a project, from budgeting and timelines to the nitty-gritty of construction and its impact on future tech.

What Are the Biggest Cost Drivers in an OSP Project?

It’s not the fiber itself. The single biggest line item on almost any OSP budget is the civil construction work. We’re talking about the heavy lifting: trenching, directional boring, and putting everything back the way you found it. This can easily eat up over 50% of the total project cost because of the intense labor and specialized machinery involved.

But that’s not the whole story. Other major expenses to watch for include:

- Labor Costs: You need skilled hands for splicing, testing, and construction, and that expertise is a significant investment.

- Permitting Fees: The paperwork adds up. Securing right-of-way access and construction permits from multiple agencies can be a surprisingly large and complex expense.

- Materials: The fiber optic cable gets the attention, but don't forget all the supporting hardware—conduits, handholes, splice closures, and more. It all adds to the bottom line.

- Make-Ready Work: This is a big one for aerial builds. Getting utility poles ready for your new cable can be a substantial, and often underestimated, cost.

How Long Does a Typical Fiber Deployment Take?

There's no single answer—timelines can vary wildly. A short fiber run to connect a new business park might be wrapped up in a few months. A full-blown, city-wide Fiber to the Home (FTTH) project? That could easily stretch across several years.

What often surprises people is that the longest part of the process happens before a single shovel hits the ground.

You should expect the initial design, engineering, and permitting stages to take six months or even longer before any physical construction can start. From there, the build-out speed depends on the total mileage, the terrain you’re dealing with, and even the weather.

Why Is Make-Ready Work So Important for Aerial Builds?

Think of make-ready as getting a room ready before you move in the furniture. It’s the essential process of preparing existing utility poles to safely carry your new fiber optic cables. This isn’t optional—it’s a strict requirement from the pole owners, which are usually power and telephone companies.

This work involves a lot more than just stringing a new line. It might mean shifting existing cables around to create space, ensuring you have safe clearance from high-voltage power lines, or even replacing old poles that simply can’t support the extra weight and tension. If you rush or skip make-ready, you’re inviting safety hazards, network damage, and hefty fines. It's a non-negotiable step for any aerial deployment.

How Does Outside Fiber Plant Support 5G Wireless Networks?

5G’s promise of lightning-fast speeds and ultra-low latency depends on a dense grid of small cell sites. But those wireless sites need a physical connection to the rest of the world, and that connection has to be incredibly fast and reliable. That’s where fiber comes in.

An outside fiber plant acts as the critical backhaul for 5G. It's the physical superhighway that transports enormous amounts of data to and from the wireless antennas. Put simply, without a deep and robust OSP network already in place, the full potential of 5G just can't happen.

Navigating an outside fiber plant project takes a partner who has been in the trenches and understands every phase, from the first sketch to the final splice. Southern Tier Resources delivers that comprehensive engineering, construction, and maintenance expertise to build a network that performs from day one and stands the test of time.