When you talk about top-tier network infrastructure, the name Corning inevitably comes up. For as long as most of us have been in the business, Corning has been the benchmark for optical fiber, providing the raw material that underpins global communications with a reputation for reliability and forward-thinking engineering.

Why Corning Is the Bedrock of Modern Networks

In the world of fiber optics, you quickly learn that not all glass is the same. Plenty of companies make optical fiber, but Corning’s deep-rooted expertise in materials science and precision manufacturing really puts them in a different league. That dedication pays off in real-world performance for network operators, data center managers, and anyone who can't afford to compromise on long-term stability and future capacity.

It’s like building a skyscraper. You wouldn’t skimp on the steel for the frame, because that one choice dictates the integrity and lifespan of the entire structure. Choosing your optical fiber is that same kind of foundational decision for a network. Corning fiber is that high-grade steel, ensuring the digital services you build on top of it are fast, dependable, and ready to scale.

Powering the AI and Data Center Boom

The need for high-quality fiber infrastructure has absolutely exploded, and a huge part of that is the rise of artificial intelligence and cloud computing. These applications demand staggering amounts of data throughput with virtually zero latency, pushing older network components past their breaking point. Corning has stepped up, engineering fiber specifically to handle these intense, data-heavy workloads.

You can see their market leadership in the numbers. As companies scramble to build out AI infrastructure, Corning's Optical Communications segment is experiencing massive demand. In fact, projections for 2025 show the segment's sales are expected to jump by 39% year-over-year to $6.5 billion. That's a powerful indicator of just how critical their products are to the future of AI data centers. For a deeper dive into these figures, you can find more analysis on S&P Global Market Intelligence.

"Generative AI is leveraging the near limitless potential of optical fiber to transmit data at light speed within and between data centers where it can then be quickly processed to create large language models which AI learns from and uses to operate."

This really gets to the heart of it. The innovations coming out of Corning aren't just minor tweaks; they are fundamental enablers for the next wave of technology. They ensure that networks won't buckle under the ever-growing torrent of global data. For those of us in the field—the contractors and engineers—deploying Corning isn't just a product choice; it's a strategic investment in reliability.

Matching Corning Fiber to Your Network Application

Picking the right optical fiber is a lot like choosing the right tool for a job. You wouldn't use a sledgehammer to hang a picture frame, and you wouldn't use a short-range, high-capacity fiber for a cross-country link. The physics and economics just don't work. The demands of a massive data center are worlds apart from a rural broadband rollout, and Corning has engineered distinct fiber families for each scenario.

Getting this choice right from the start is fundamental. It affects everything from your initial build cost to the network's future performance and scalability. Let's dig into the main categories to see which fiber best suits your project.

Single-Mode Fiber: The Long-Haul Workhorse

Think of single-mode fiber as an express lane for light. It has an incredibly narrow core—typically just 9 micrometers in diameter—that forces light to travel in a single, straight path. This design practically eliminates signal distortion (modal dispersion), allowing data to speed across enormous distances with very little power loss.

Because of this, the Corning SMF-28® family has become the go-to standard for networks where distance is the primary challenge:

- Long-Haul Routes: Linking cities, states, and even countries.

- Carrier Backbones: Building the core infrastructure that powers ISPs and telecommunication giants.

- Submarine Cables: Spanning entire oceans to connect continents.

For these critical applications, achieving maximum reach and preserving signal integrity isn't just a goal; it's a requirement. Single-mode is the only practical solution.

Multimode Fiber: Built for High-Density, Shorter-Reach Environments

If single-mode is the express lane, multimode fiber is the bustling multi-lane artery inside a city. Its much larger core (50 or 62.5 micrometers) allows multiple modes of light to travel at once. This approach is perfect for moving massive amounts of data over shorter distances, like within a single building or across a campus.

Corning’s ClearCurve® multimode (OM) fibers are specifically designed for the tight, complex pathways inside modern data centers. Their claim to fame is exceptional bend performance. You can route these cables around sharp corners in server racks and crowded trays without causing the signal degradation that would cripple a less forgiving fiber.

Your choice of fiber is a foundational decision. It's not just a technical spec—it's a strategic one that directly impacts your network's performance, reliability, and total cost of ownership. The key is to match the fiber's capabilities to the real-world demands of your project.

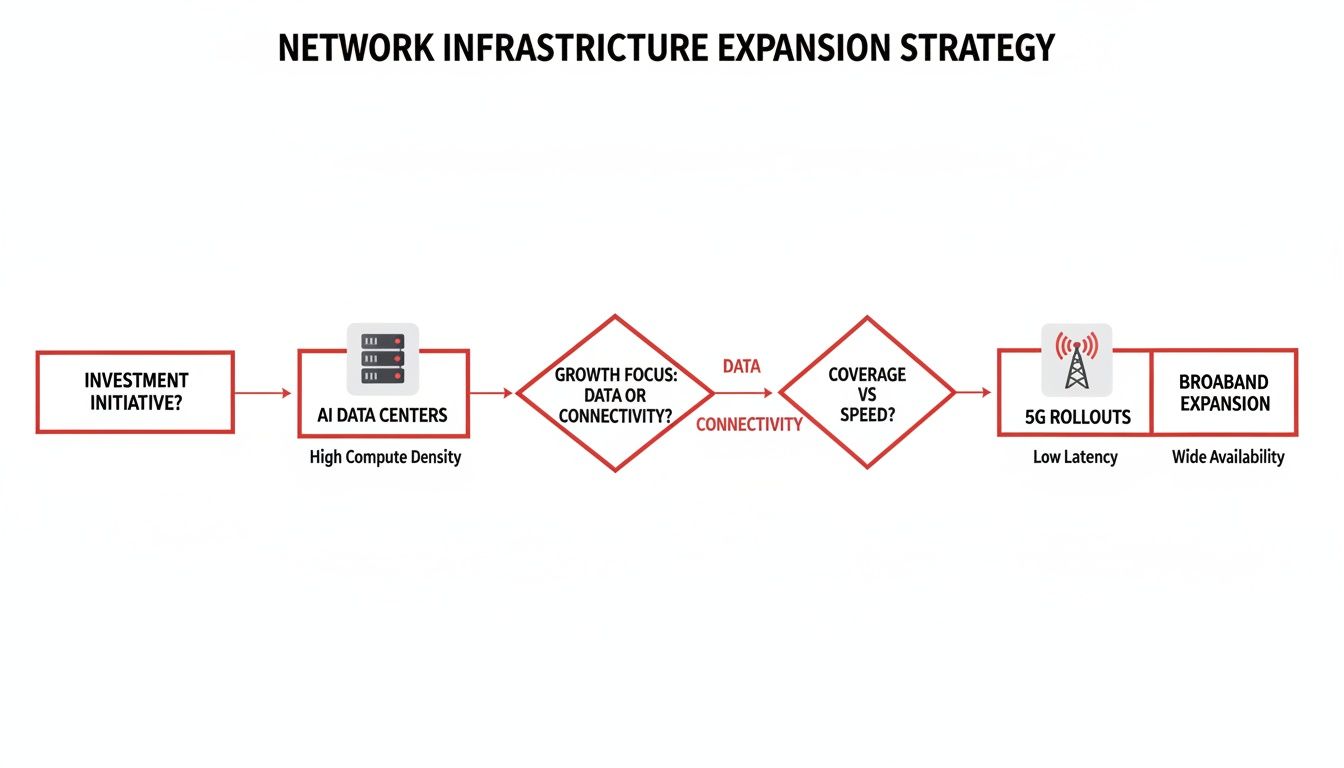

This flowchart shows how different network initiatives often lead to a specific fiber choice.

As you can see, goals like building out AI data centers or expanding 5G coverage point toward different fiber solutions—from high-density multimode for internal traffic to long-reach single-mode for connecting cell towers.

The hunger for high-performance multimode fiber in data centers is staggering. For a real-world example, look no further than the massive $6 billion multi-year deal between Corning and Meta Platforms. This 2025 agreement guarantees a supply of advanced fiber optic cables through 2030, directly supporting Meta's aggressive expansion of its AI infrastructure. You can learn more about how Corning is responding to this massive demand for fiber optics.

Corning Optical Fiber Product Family Comparison

To make the decision clearer, this table breaks down the primary fiber families, their key features, and where they fit best.

| Fiber Family | Core Type | Key Feature | Primary Application | Best For |

|---|---|---|---|---|

| SMF-28® Family | Single-Mode | Long-distance transmission, minimal signal loss | Carrier backbones, long-haul | Spanning vast geographic distances with high signal integrity. |

| ClearCurve® OM3/OM4 | Multimode (50µm) | High bandwidth, superior bend performance | Data centers, enterprise LAN | High-speed, short-reach links inside buildings and between racks. |

| ClearCurve® OM5 | Multimode (50µm) | Supports short-wavelength division multiplexing (SWDM) | Next-gen data centers | Future-proofing data center interconnects for 400G and beyond. |

| SMF-28® ULL | Single-Mode | Ultra-low attenuation for maximum reach | Submarine, terrestrial long-haul | Extreme-distance links where every decibel of signal loss counts. |

| ClearCurve® ZBL | Single-Mode | Zero-water-peak, bend-insensitive | FTTx, access networks | Deployments in tight spaces like MDU closets and residential drops. |

This comparison highlights a critical point: there is no single "best" fiber. The ideal choice is always the one that is purpose-built for the environment it will operate in.

Specialty Fibers for Unique Environments

Sometimes, a standard single-mode or multimode fiber just won't cut it. For those edge cases, Corning produces a range of specialty fibers engineered for extreme or unusual conditions.

We're talking about hermetically sealed fibers for high-humidity environments, radiation-resistant fibers for aerospace and defense, and even custom patch cords built to handle high-power industrial lasers. These aren't your everyday products, but knowing they exist is vital when you're faced with a challenge that a standard solution can't solve. You can explore a variety of these specialized fiber optic cords and their applications to get a sense of the possibilities.

Understanding the Key Specs That Define Fiber Performance

To build a network that lasts, you have to get past the product names and really dig into the numbers on the spec sheet. For Corning optical fiber, these specifications aren't just abstract details—they're direct predictors of how that fiber will behave out in the field. Once you get a handle on these metrics, you can translate raw data into real-world reliability and long-term value for your network.

Let's walk through the three most important performance specs that every network architect and engineer obsesses over. Understanding these will give you the confidence to pick the right fiber for the job.

Attenuation: The Measure of Signal Loss

Think of attenuation like the beam from a flashlight. Right in front of you, it’s intensely bright, but as you point it further down a dark hallway, the light gets progressively dimmer. That's exactly what happens to a light signal inside an optical fiber.

Attenuation measures this gradual loss of signal strength, and we express it in decibels per kilometer (dB/km). It’s simple: a lower number is always better. It means your signal can travel much farther before it gets too weak and needs a boost from an amplifier.

Take Corning's SMF-28® Ultra-Low Loss (ULL) fiber. It was engineered specifically to minimize this signal decay, making it the go-to choice for transoceanic submarine cables and long-haul terrestrial routes where every fraction of a decibel matters. Less signal loss means you need less expensive amplification equipment, which cuts down on both upfront capital and ongoing operational costs. You can learn more about how signal loss impacts network performance in our dedicated guide.

Bandwidth: The Data Capacity Superhighway

Bandwidth is all about how much data the fiber can carry at once. A great analogy is a highway: a two-lane road can only handle so much traffic before it gets jammed, while a ten-lane superhighway lets a massive volume of cars flow freely.

In fiber optics, higher bandwidth means more data can be transmitted at the same time. This isn't a "nice to have"—it's an absolute must for handling today's workloads like 4K video streams, cloud services, and AI.

This is where the difference between single-mode and multimode fiber really comes into focus:

- Single-Mode Fiber: Essentially offers near-limitless bandwidth. It's built for the long haul and is the most future-proof option for networks that need to scale.

- Multimode Fiber: Delivers extremely high bandwidth, but over shorter distances. It’s perfect for the high-density, high-traffic environment inside a data center.

Choosing fiber with enough bandwidth ensures your network won't just keep up with today's traffic, but will be ready for the explosive data growth we all know is coming.

Bend Insensitivity: Handling Real-World Imperfections

In a perfect lab setting, you can lay fiber out in a perfectly straight line. But that's not the real world. Out in the field, cable has to navigate tight corners in conduits, snake through crowded equipment racks, and handle less-than-ideal installation conditions.

This is where bend insensitivity becomes a game-changer. Standard optical fibers are fragile; bend one too tightly, and the light signal literally leaks out, causing massive signal loss. This problem is called macrobending.

Bend-insensitive fiber, like Corning’s celebrated ClearCurve® line, is engineered to maintain a strong, clean signal even when tied in knots. This isn’t a luxury feature; for modern, high-density deployments, it's a necessity.

Corning’s work in this area is especially critical for data centers. With AI clusters demanding up to 36 times more fiber connections per rack, you need fiber like SMF-28® Ultra that can handle the density without signal degradation. This surge in demand solidifies Corning's importance and ensures that partners like us at Southern Tier Resources have a steady supply chain to complete fiber builds and handle ongoing maintenance. You can find more on Corning's role in the AI infrastructure boom from S&P Global.

Where the Rubber Meets the Road: Real-World Fiber Applications

Specifications on a datasheet are one thing, but the real test of a fiber is how it performs in the complex, demanding network architectures that keep our world running. High-quality Corning optical fiber isn't just another component; it's the fundamental building block of modern connectivity.

From your home internet connection to the massive data centers powering cloud services, specific fiber choices make these incredible feats of engineering possible. Let's look at how these products connect a spool of glass to the seamless video calls and AI-driven tools we rely on every day.

Fueling Fiber-to-the-Home (FTTH) Networks

For Internet Service Providers (ISPs), the mission is clear: deliver fast, reliable internet to subscribers. Fiber-to-the-Home (FTTH) is the undisputed champion of broadband delivery, and it runs on single-mode, bend-insensitive fibers like Corning’s ClearCurve® ZBL.

Think about the journey that fiber takes inside a building. Installers are constantly navigating tight corners, stapling cable along baseboards, and fishing it through crowded conduits in apartment complexes. A standard fiber would lose signal with every sharp turn, but ClearCurve® is designed to handle this abuse, maintaining signal integrity even when bent. This drastically simplifies installation, cuts down on truck rolls for repairs, and ensures customers actually get the speeds they’re paying for.

In FTTH deployments, you need a fiber that's not just fast, but also tough and forgiving. The goal is to build a "last mile" that's resilient and cost-effective to install and maintain for decades.

Powering Hyperscale Data Centers and AI Clusters

Inside a modern data center, the game changes completely. Distances are much shorter, but the sheer density of data is staggering. Today's leaf-spine architectures require a web of connections between thousands of servers, a need that has exploded with the rise of AI. Here, both low-loss and bend-insensitive fibers are absolutely critical for managing the extreme cabling density inside server racks.

Corning is at the forefront of this evolution. A prime example is their 2025 partnership with Broadcom on co-packaged optics (CPO) for AI infrastructure. By supplying key components for the 51.2 Tbps Bailly Ethernet switch, they are helping to create the high-bandwidth, high-efficiency backbone required for large-scale AI operations. This kind of innovation is why the global fiber optic market is expected to jump from $9.26 billion in 2025 to $15.79 billion by 2033. For a deeper dive, you can read more about how Corning’s strategy is driving long-term growth in the fiber optics sector.

Enabling Long-Haul and DWDM Systems

When you need to move massive amounts of data across states or oceans, you enter the world of long-haul networks. This is the domain of Dense Wavelength-Division Multiplexing (DWDM), a brilliant technology that sends dozens of light signals down a single fiber at once, each on its own color, or wavelength.

This kind of system demands the purest glass with the lowest possible signal loss. Corning's SMF-28® ULL (Ultra-Low Loss) fiber is the gold standard here. Its ability to carry a signal for hundreds of kilometers with minimal decay means carriers need fewer expensive optical amplifiers along the route. This directly lowers both the build-out and operational costs, making it the bedrock of the submarine and terrestrial backbones that connect our continents.

Deployment, Splicing, and Testing in the Field

Choosing a premium fiber like Corning is just the first step. The real test of your network's performance happens out in the field. This is where meticulous deployment practices separate a flawless system from a network that’s a constant source of troubleshooting headaches.

Even the most advanced fiber is only as good as its weakest link. More often than not, that weak link is a poorly executed splice or an undocumented connection.

The foundation of a reliable network is the fusion splice, a process where technicians precisely align and melt two fiber ends together into one seamless, permanent connection. The goal is to create a splice so perfect that light passes through with almost zero reflection or signal loss.

A low-loss splice isn't just a "nice-to-have"—it's a requirement. The industry benchmark for a high-quality fusion splice is a loss of less than 0.05 dB. It sounds minuscule, but those tiny losses add up across a link and can seriously degrade performance, especially over long distances.

Splicing Corning Fiber the Right Way

Hitting that <0.05 dB target demands skill, the right tools, and an almost obsessive attention to detail. Cleanliness is everything. A single speck of dust, invisible to the naked eye, can ruin a splice and create a point of failure that might not show up until the network is live and under load.

Here’s what professional field deployment actually involves:

- Meticulous Prep Work: Technicians must carefully strip, clean, and cleave each fiber end to create a perfectly flat, perpendicular face. It's a craft.

- High-End Splicers: Modern fusion splicers use automated alignment systems to ensure the cores of the two fibers line up perfectly before an electrical arc fuses them together.

- Controlling the Environment: Whenever possible, we work in clean, controlled spaces like a dedicated splicing trailer to keep dust and moisture out.

This methodical approach is how we ensure the low-loss potential of Corning fiber is actually delivered in the final, installed link.

Validating Performance with Rigorous Testing

Once the splices are done, the work isn't over. The next phase is comprehensive testing and certification. This isn't just a simple continuity check; it's about creating a detailed performance baseline that will serve the network for its entire lifecycle. For a closer look, you can read our guide on network performance validation and testing.

Two tools are absolutely essential here.

The first is an Optical Time Domain Reflectometer (OTDR). This instrument sends a pulse of light down the fiber and analyzes the reflections that bounce back. Think of it as radar for your fiber link. It creates a detailed map showing:

- Total Link Distance and Loss: Verifying the cable run's actual length and total signal attenuation.

- Splice and Connector Quality: Pinpointing the exact location and loss measurement of every connection.

- Fault Location: Finding the precise location of breaks, bad bends, or other problems.

Next, technicians use an Optical Light Source and Power Meter (OLTS). This provides the definitive, end-to-end insertion loss—a clear pass/fail result based on the project's design specifications. It confirms the link can handle the data it was built for.

By combining these two tests, we can deliver a fully documented, high-performance network that meets the strict demands of today's data centers and carrier-grade infrastructure.

So, What Does This All Mean for Your Network?

Choosing the right optical fiber from Corning isn't just about ticking a box on a spec sheet; it's a foundational decision for the future of your network. It’s about building a digital infrastructure that you can rely on for years, even decades, to come. As we've walked through, getting this right starts with matching the fiber to the job—whether that's a long-haul single-mode run or a bend-insensitive multimode cable for a tricky data center install.

Knowing the difference between attenuation and bandwidth helps you look at a datasheet and understand exactly how that fiber will perform in the real world. But here's the thing: the best fiber in the world is only as good as the team that puts it in the ground. The true potential of Corning's engineering is only unlocked through expert deployment—from meticulous fusion splicing to comprehensive testing with an OTDR and OLTS.

A network is only as strong as its weakest link. Investing in premium fiber without committing to expert installation is like buying a race car and skipping the professional pit crew—you'll never unlock its true performance.

Bringing It All Together: From a Spool of Glass to a Live Network

Turning a reel of fiber into a living, breathing network that’s ready for the future takes a partner who sees the big picture. That’s where we come in. At Southern Tier Resources, we manage the entire process, from designing the initial pathways and selecting the perfect Corning fiber to pulling the cable, splicing it with precision, and certifying every single strand.

Our job is to handle all the technical details so you can focus on what you do best: delivering services to your customers. We build networks that aren't just turned on; they're optimized, documented, and ready for whatever comes next. It’s about giving you the confidence that your infrastructure is built to last.

Your Questions Answered: Working with Corning Fiber

When you're planning a fiber optic project, the details matter. You're building infrastructure that needs to last for decades, so it's natural to have questions. Here are a few of the most common ones we hear from clients about using Corning fiber in their networks.

Can I Splice Corning Fiber to Other Brands?

Absolutely. Corning designs its fiber to meet strict international standards, like ITU-T G.652.D for standard single-mode. This standardization is key because it guarantees that a Corning fiber will play nice with fibers from other manufacturers, allowing them to be spliced together without major issues.

That said, the best-case scenario is always consistency. For the cleanest signal and most predictable performance, we recommend sticking with the same type of fiber throughout a single link. Mixing an ultra-low-loss fiber with a standard one, for example, can introduce a slight performance dip at the splice point due to the mismatch in their core properties. It works, but it's not ideal.

What's the Real-World Lifespan of Corning Fiber?

When installed correctly inside a quality cable, you can expect Corning optical fiber to perform reliably for over 30 years. The glass core itself is incredibly resilient and doesn't really "age" or degrade chemically. It's built for the long haul.

The real threats to a fiber's lifespan aren't internal; they're external. The things that cause failures are almost always physical: a backhoe cutting a line, a technician bending a cable too tightly, water getting into a poorly sealed splice case, or even wildlife chewing through a conduit. The fiber itself is rarely the point of failure.

This incredible durability is why fiber is considered a true long-term investment in your infrastructure.

Where Does Hollow Core Fiber Fit into the Picture?

Hollow Core Fiber is a fascinating new frontier. Instead of a solid glass core, light travels through an air channel inside the fiber. This simple change has a massive impact: data can move up to 47% faster than it does through traditional glass.

While Corning wasn't the original inventor, they've become a critical partner in bringing this technology to the mainstream. Microsoft, for instance, has tapped Corning to help manufacture Hollow Core Fiber at scale for its massive Azure data centers. This move shows just how central Corning is to pushing the industry forward, especially as the demands of AI and cloud computing grow.

At Southern Tier Resources, our job is to make sure every single component of your network is built for performance and a long, reliable life. If you're ready to build next-generation infrastructure with the industry's best materials, get in touch with our team.