Cable contractor companies serve as the foundation for today’s connected world. They blend field expertise with detailed planning to guide power, fiber, and data lines from drawing board to live network.

Why Cable Contractor Companies Matter

From initial site surveys to final performance checks, these firms handle every stage with precision. Their teams tackle feasibility studies, engineering design, trenching, splicing, testing, and ongoing maintenance.

Picking the right contractor keeps your rollout on schedule and helps avoid hidden cost overruns.

Core Offerings And Roles

- Project Planning & Feasibility Studies that set clear milestones and realistic budgets

- End-to-End Installation covering trenching, cable pulling, splicing, and system testing

- Compliance Management to secure permits, meet safety standards, and navigate regulations

“Smooth coordination is the conductor that keeps every phase in harmony,” notes a veteran cable project lead.

This guide lays out how to evaluate providers, decode technical terms, and steer the procurement process. Real case studies highlight common stumbling blocks and proven success factors for carriers, ISPs, data centers, and municipalities.

Key Outcomes

- Faster network deployment with minimal downtime and controlled budgets

- Single-point accountability for transparent communication and issue resolution

- Flexible maintenance plans that scale as network demands grow

Understanding these benefits gives you the confidence to launch projects and mitigate unseen risks.

What You Will Explore

- A step-by-step breakdown of services, from feasibility through maintenance

- Technical and commercial evaluation criteria for side-by-side provider comparisons

- Customizable RFP templates and procurement checklists to streamline bidding

- Real-world case studies showcasing wins and lessons learned

- Critical contract and SLA guidelines to safeguard your investment

Dive into each section to build a solid framework for choosing and partnering with cable contractor companies. Your network’s reliability starts here—let’s get going!

Understanding Core Cable Concepts

Imagine a cable contractor as a master chef in a bustling kitchen. Manufacturers write the recipes—detailed formulas dictating conductor size, insulation type, and jacket material. Contractors then blend these components on-site, adjusting for each project’s unique flavor.

Each cable family serves its own purpose.

Power cables spark lights and drive motors.

Fiber cables carry massive data loads across miles.

Data cables shuttle office traffic and local network signals.

Site conditions and local rules shape the layout of any cable network. Rocky soil might call for heavy-duty trenchers. In damp regions, moisture-resistant jackets become non-negotiable. That’s why early site surveys are the compass guiding design choices.

Core Cable Types And Uses

| Cable Type | Typical Use |

|---|---|

| Power | Electrical distribution |

| Fiber | Telecom and broadband links |

| Data | LAN and building networks |

Before issuing a quote, contractors walk the site, review engineering drawings, and cross-check local codes. They translate plans into on-the-ground actions, lining up permits, safety inspections, and crew schedules to hit tight deadlines.

“Cabling projects succeed when design meets skilled execution,” says a seasoned telecom engineer.

The global industrial cables market is projected to reach USD 128.51 billion by 2025 and USD 155.92 billion by 2032 at a CAGR of 2.8%, driven by power transmission, renewable energy, and infrastructure expansions worldwide. Learn more about market findings from Coherent Market Insights.

Read also our guide on broadband and telecom services for carrier-focused solutions.

Market Drivers And Project Mapping

Infrastructure upgrades—like grid modernization—fuel growth in power cabling. Rural broadband pushes fiber deeper into the countryside. Municipal energy schemes expand medium-voltage networks for public utilities.

Here’s a quick checklist to map services to project needs:

- Define project scope and pinpoint required cable types

- Analyze soil composition and environmental factors

- Review regulatory approvals and safety standards

- Set maintenance plans and lifecycle goals

For example, a rural fiber deployment often favors long-haul fiber with minimal splicing. A data center build, by contrast, demands high-density data cabling, precise labeling, and detailed test records.

Deliverables such as test reports and as-built schematics verify performance and simplify future expansions. With these core concepts under your belt, you’ll be ready to vet providers and speak the language of cabling.

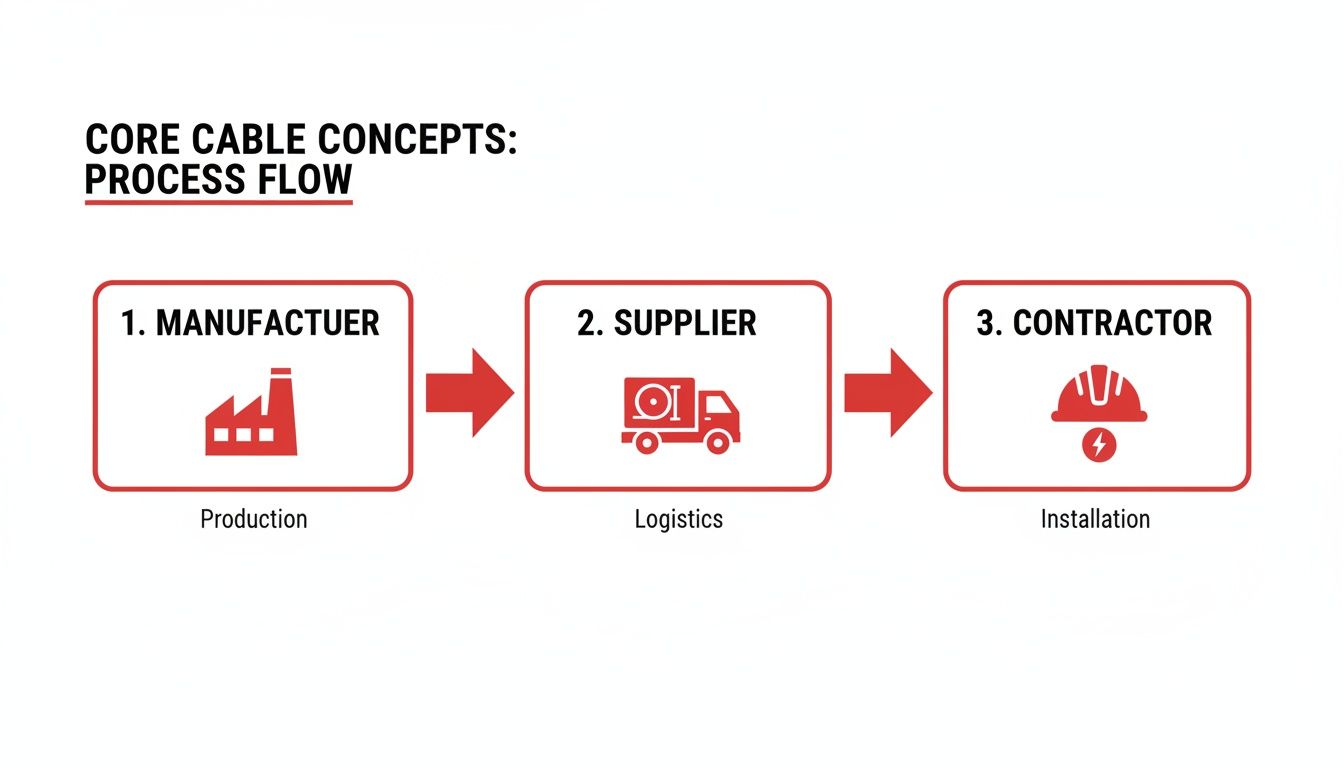

Roles Of Manufacturers And Suppliers

Manufacturers define cable specs, rigorously testing for tensile strength and conductivity. Suppliers become the logistics engine, handling inventory, warehousing, and delivery windows.

Key supply chain tasks include:

- Matching stock levels to project timelines

- Conducting pre-dispatch quality inspections

- Coordinating precise delivery schedules with contractors

This layered approach keeps materials flowing smoothly and on spec. Recognizing each player’s role helps project managers align schedules and sidestep bottlenecks.

Understanding this chain completes your foundation and equips you to compare cable contractor companies effectively.

Next we will dive into mapping core services to your project scope.

Mapping Core Services

Cable contractor firms divide a project into clear phases, guiding everyone from start to finish. Think of it like following a trusted recipe: each step keeps the work on track and predictable.

They monitor materials from the factory gate all the way to the job site, assigning accountability at every handoff.

This visual highlights a straightforward flow—factory, transport, and on-site delivery—while calling out three core roles responsible for material tracking.

Planning And Feasibility

Surveyors and project leads kick off by mapping terrain, reviewing regulations, and sizing up costs. Deliverables here often include route studies and budget forecasts with a 10–15% contingency.

- Detailed route surveys covering soil type, access points, and right-of-way issues

- A permitting overview listing all municipal and state approvals

- Resource schedules aligning crews, equipment, and materials

“Thorough upfront feasibility cuts delays and keeps costs predictable,” says a telecom infrastructure manager.

Core Service Comparison

Before moving deeper, review how each key service lines up in terms of deliverables, timelines, and team responsibilities.

Core Service Comparison

| Service Category | Key Deliverables | Typical Timeline | Stakeholder Roles |

|---|---|---|---|

| Project Planning | Route maps, cost forecasts, permit packs | 2–4 weeks | Planners, Surveyors |

| Engineering Design | Detailed schematics, spec sheets | 3–6 weeks | Engineers, CAD staff |

| Permitting | Approval documents, environmental reports | 4–8 weeks | Legal, Compliance |

| Trenching And Laying | Excavation logs, install layouts | 1–3 weeks | Field Crew, Operators |

| Splicing And Testing | Splice reports, OTDR readouts | 1–2 weeks | Technicians, QA |

| Commissioning | Performance tests, sign-off certificates | 1 week | Inspectors, QA Leads |

| Maintenance And Support | Preventive schedules, SLA dashboards | Ongoing | Support, Maintenance |

Use this snapshot to weigh each service’s timeline, deliverables, and responsible teams when selecting a partner.

Engineering Design And Permitting

Once routes are set, engineers turn sketches into build-ready drawings. They calculate load specs, conduit sizes, and bend radii to protect cable life.

Permitting experts then tackle forms across jurisdictions and organize community reviews. By tracking submission deadlines and feedback loops, they keep approvals moving smoothly.

Trenching And Cable Laying

Field crews follow GPS-guided trench plans, digging to the exact depth and clearance needed to avoid existing utilities. Cables are laid in neat reels, marked with warning tape, then backfilled and compacted to prevent settling.

Safety officers conduct shoring checks and PPE audits. Unexpected rock or high water tables can mean on-the-fly design tweaks.

Splicing Testing And Commissioning

Technicians perform fusion or mechanical splices, tagging each joint for full traceability. Quality control teams run OTDR checks to ensure signal loss stays under 0.3 dB per splice.

After tests pass, commissioning involves system load checks and final sign-off certificates. Any discrepancies trigger quick corrective work under change-order protocols.

Maintenance And Support

Maintenance crews schedule regular inspections, drone flyovers, and thermal scans. They keep an eye on targets like 99.9% uptime for mission-critical links.

Best practices include:

- Automated dashboards with threshold alerts

- On-call teams ready for emergency repairs

- Annual reviews to update life-cycle plans

For more on deployment tactics, check https://southerntierresources.com/fiber-optic-construction/.

With this phase-by-phase map, you can spot hidden costs—overtime, permit fees—and demand itemized cost tables. That clarity keeps projects on time and on budget.

Evaluation Criteria For Cable Contractor Companies

Selecting a cable contractor can feel like composing an orchestra: every player—from trench crews to testing technicians—needs to hit the right note.

Evaluating their technical chops is your first line of defense. You want proof that they can manage ground prep, fiber splicing and rigorous testing without tripping over regulations or safety hazards.

Technical Criteria To Evaluate

- ISO 9001 and NEBOSH certifications signal adherence to strict quality and safety regimes.

- Ownership of specialized equipment—trenchers, tensioners, fiber fusion splicers—shows they’re ready on day one.

- A documented quality control process with clear steps for inspection, testing and traceability.

- A safety record boasting incident rates below 0.5%, backed by regular audits.

These technical checks form the bedrock of a reliable bid. Skip them, and you risk costly rework or compliance headaches.

Commercial Criteria To Evaluate

- Financial stability measured through current debt ratios and consistent cash flow statements.

- Insurance policies that cover general liability, workers’ compensation and equipment loss.

- References demonstrating on-time delivery and strict budget discipline.

- Transparent pricing models with unit rates, mobilization fees and clear change-order rules.

Weight each item based on project priorities. A balanced approach keeps commercial and technical factors in sync.

To keep comparisons fair and transparent, here’s a breakdown of how each factor contributes to the overall score:

Evaluation Criteria Matrix

| Criterion | Weight (%) | Score Range | Total Points |

|---|---|---|---|

| Certifications And Safety | 20% | 1–10 | 200 |

| Equipment And Tools | 15% | 1–10 | 150 |

| Quality Control Workflow | 15% | 1–10 | 150 |

| Financial Stability | 20% | 1–10 | 200 |

| Past Performance | 15% | 1–10 | 150 |

| Pricing Transparency | 15% | 1–10 | 150 |

This matrix gives you a clear snapshot of how bids stack up against your must-have criteria.

Validation And Shortlist Verification

Once scores are in, roll up your sleeves. A site visit acts like a trial run—inspect vehicles, meet crews and watch safety drills in action.

Think of reference interviews as test drives before buying a car. Ask how contractors respond to tight deadlines or sudden weather setbacks.

Bringing in an independent auditor adds another layer of confidence. They’ll verify certifications, sift through safety logs and validate test records.

Many top firms align with leading manufacturers setting industry standards. Prysmian Group, Sumitomo Electric and Nexans control over 40% of the global market, establishing benchmarks in power, telecom and data projects. Read the full research about wire and cable market share here.

A methodical, weighted process cuts uncertainty and leaves a solid paper trail for your final selection.

Best Practices For Evaluation

Embed your criteria in the project scope and map out risk tolerance from the start.

Set a pass/fail threshold to eliminate underperforming bids instantly.

Assemble a cross-functional team:

- Engineers for technical feasibility and constructibility reviews.

- Safety officers to validate site protocols and emergency response plans.

- Financial analysts to confirm cost assumptions and budget fit.

- Project managers to vet timelines and resource allocations.

Keep an audit log of every score and interview note. Clear documentation safeguards the procurement process and feeds into continuous improvement for the next selection cycle.

Creating RFPs And Procurement Checklists

A well-crafted RFP lays the groundwork for choosing the ideal cable contractor companies. It spells out your project’s goals, standards, and expectations—making it easier to compare submissions side by side.

Use a structured RFP to cover:

- Scope Definition with clear deliverables and acceptance criteria

- Technical Specifications including cable types, testing protocols, and equipment standards

- Qualification Requirements such as certifications, safety records, and relevant experience

Additionally, break pricing into unit rates, mobilization fees, and change-order terms. This level of clarity paves the way for smoother negotiations.

“A detailed RFP cuts ambiguity and accelerates award decisions,” says a procurement lead.

Setting Realistic Procurement Timelines

Striking the right balance between thorough review and a swift contracting process is key. Opening the Q&A window early keeps bidders engaged and prevents last-minute rushes.

Aim for a 30-day response period on full proposals. Allocate 10 days for clarifications and site-visit requests.

Structure your bidder communications like this:

- Issue a formal Q&A process with clear submission deadlines

- Log every question and answer in a shared addenda document

- Publish each addendum with time stamps and revision notes

Manage addenda carefully to avoid scope drift. Assign each update a unique reference number and distribution list.

RFP Elements Checklist

Below is a quick reference table of the main RFP sections and what you need to include. Use it to confirm you haven’t missed anything critical before you issue the RFP.

RFP Elements Checklist

| RFP Section | Purpose | Required Documentation |

|---|---|---|

| Scope Definition | Clarify project boundaries and deliverables | Project brief, route maps, as-built references |

| Technical Requirements | Specify cable specs, test protocols, and standards | Cable datasheets, test procedures, equipment certifications |

| Qualification Criteria | Verify bidder competence and safety record | CVs, safety logs, ISO/NEBOSH certificates |

| Pricing Format | Standardize cost comparisons | Unit rate schedule, mobilization fees, change-order rules |

| Safety and Environment | Cover compliance and mitigation plans | Risk assessments, environmental permits, PPE plans |

| Timeline Management | Set submission, Q&A, and award dates | Gantt chart, calendar of milestones |

| Addenda Tracking | Manage changes to the RFP | Version logs, distribution list, amendment notes |

Use this checklist as a starting point. Confirm sign-offs for each item before sending the RFP out.

Best Practices For RFP Success

Before you go live, gather your legal, safety, and technical teams for a review. Early alignment prevents costly revisions down the road.

- Maintain version control on all RFP documents

- Host a bidder conference to walk through key requirements and address questions in real time

- Archive every piece of correspondence and addendum for audit trails and future reference

These steps can save weeks in award cycles and keep your budget on track.

Wrapping Up Your RFP And Procurement Process

Once evaluations wrap, validate vendor confirmations and finalize the contract draft. Make sure you’ve collected insurance certificates, safety plans, and compliance documents.

Your award notice should spell out:

- Next steps and mobilization dates

- Payment schedule

- Primary points of contact

A clear transition plan cuts down on startup confusion and speeds up on-site work.

Key Takeaways:

- Your RFP must be detailed.

- Timelines should be realistic.

- All stakeholders need clarity on evaluation metrics.

With a solid RFP and procurement checklist in hand, you’ll streamline vendor selection, manage risk, and keep cable projects on schedule.

Example Timeline For Cable Project RFP

Here’s a sample 45-day schedule that blends bidding, evaluation, and award:

- Day 1: Publish RFP and notify bidders

- Days 2–7: Q&A window for site inquiries

- Days 8–25: Evaluate proposals and scoring

- Days 26–45: Final interviews, contract award, and kickoff

Adjust these milestones to fit your project’s scale and complexity. Use this framework to guide your procurement timeline.

Begin your RFP.

Case Study Examples With Real Projects

Real-world examples reveal how cable contractor companies confront unique site conditions, tight schedules, and technical hurdles. You’ll discover project goals, obstacles, solutions, and measurable outcomes.

These four stories—from a rural fiber rollout to a wind farm link—offer practical takeaways and cautionary notes for your next cable construction effort.

Rural Broadband Fiber Rollout

Building out fiber in sparsely populated zones demands close coordination with local authorities and inventive installation methods. In this case, a team installed 80 kilometers of single-mode fiber to serve three rural towns on a six-month clock.

- Goal: Connect 1,200 households to reliable broadband

- Challenge: Rocky terrain slowed trenching; permit approvals lagged

- Solution: Phased micro-trenching plus modular permitting workflow

Fusion-splicing crews kept average splice loss below 0.1 dB. Downtime never exceeded two days per segment, leading to 99.7% uptime in Year 1 and faster permit renewals thanks to positive community feedback.

“Engaging town councils right out of the gate cut our approval time by 20%,” recalls the project manager.

Municipal Medium Voltage Upgrade

Replacing aging cables in a live city grid tests even seasoned crews. Here, teams rerouted 50 MVA circuits without interrupting power to hospitals, data centers, or traffic signals.

- Goal: Increase service reliability for 200,000 residents

- Obstacle: Live-line work steps meters from critical care wings

- Innovation: Hot-stick techniques paired with real-time thermal scanning

Safety officers logged zero lost-time incidents, and switch-over durations dropped by 30%, minimizing customer complaints.

“Staging live-line drills ahead of time was our secret to zero downtime,” notes the site safety lead.

Tip: Pre-position all live-line tools on-site to avoid premium rentals—a move that saved $15,000.

Hyperscale Data Center Build

In this 100,000 sq ft facility, crews pulled 2,500 high-density MPO and LC fiber runs on a tight schedule alongside power systems.

- Obstacle: Overlapping power and telecom teams created potential clashes

- Solution: Cross-discipline crews and double-shift rotations

- Outcome: Completed two weeks early with 0.2 dB average loss

Detailed labeling, fiber-ID tables, and test logs smoothed the handover and future audits. The hyperscale operator praised the seamless coordination.

Lesson: Early power-design reviews with cable teams slash rework by 40%.

This sector’s growth is significant. The cable construction services market is projected to reach USD 150 billion in 2025 with a 7% CAGR through 2033. Learn more about these market trends on Archive Market Research.

Wind Farm Interconnection

Connecting a 30-turbine wind farm called for 20 kilometers of armored power cable across varied soils—from sandy stretches to marshy wetlands.

- Goal: Deliver 45 MW to the main substation

- Challenge: Wet trenches prone to collapse during rain

- Adaptive Measure: Geo-synthetic liners and on-site pump stations

Moisture sensors and daily site reports kept setbacks to a minimum. Six-month load tests recorded 98.5% transmission efficiency.

Best Practice: Build dynamic schedules around weather patterns to dodge delays.

This tactic averted three rain-related work stoppages.

Key Lessons Learned

- Early stakeholder engagement accelerates permits and builds trust

- Hot-stick live-line work avoids long outages

- Cross-discipline coordination prevents clashes and speeds delivery

- Adaptive measures like geo-liners address site-specific risks

- Thorough documentation supports audits and future upgrades

Apply these proven strategies to ensure predictable timelines, high performance, and clear communication on your next cable project.

Contract and SLA Considerations

Think of a contract as the roadmap for your project. It lays out milestones, responsibilities, and what happens if you veer off course.

Strong contracts and SLAs form a safety net—protecting you from unexpected delays and runaway costs.

Essential Contract Clauses

- Scope of Work defines exactly what’s included—and what’s off the table. This keeps scope creep at bay.

- Performance Guarantees set measurable targets like response times and uptime. Miss a goal, and liquidated damages may apply.

- Warranty Terms spell out repair or replacement windows for faulty equipment.

- Change-Order Procedures clarify who approves adjustments, how costs shift, and how schedules adapt.

These clauses act as your first line of defense against surprises in schedule or budget.

Key SLA Metrics

In an SLA, metrics turn promises into hard numbers. Choose those that link directly to rewards or penalties:

- Response Time for urgent repairs, often a 4-hour window.

- Uptime Guarantee, typically 99.9% for critical sites like data centers.

- Acceptance Criteria such as OTDR loss limits or load-test benchmarks.

When a metric slips, a clear compensation or remediation path kicks in—keeping both parties aligned.

Risk And Dispute Management

Balancing liability requires clear risk-sharing and insurance clauses:

- Define a step-by-step negotiation process with set deadlines to avoid drawn-out disputes.

- Specify mediation and arbitration venues for swift legal recourse.

- Allocate responsibility for legal fees and expert-witness costs.

Think of this framework as a safety harness during a technical climb—it protects all stakeholders under pressure.

Continuous Improvement Practices

Contracts shouldn’t be stagnant. Schedule regular SLA reviews to refine performance and cut repeat issues.

Include root-cause analysis for any outage or missed target to turn raw data into insights.

“A living agreement evolves through continuous feedback,” notes our senior project manager.

Best practices include quarterly performance meetings and shared dashboards. Track trends like repair turnaround, repeat failures, and compliance rates.

Learn more in our comprehensive Data Center Services guide.

Finalizing Your Agreement

Before launch, secure executive sign-off on both contract and SLA documents. Then, store every version—drafts, amendments, performance reports—in a central repository.

| Final Steps | Purpose | Owner |

|---|---|---|

| Signature Collection | Confirm legal and executive approvals | Project Lead |

| Version Control | Track amendments and maintain document clarity | Legal Team |

| Kickoff Meeting | Align teams on contract terms and SLA goals | PMO |

| Monitoring Setup | Launch real-time performance dashboards | Operations |

Circulate a concise summary of key clauses and SLA targets. Use it as a living reference to drive transparency.

Return to your contract data regularly to spot patterns early. Engage cross-functional teams each quarter to share insights, troubleshoot gaps, and celebrate improvements in downtime, response times, and compliance.

Encourage contractors to suggest SLA tweaks based on field feedback, equipment upgrades, or emerging norms. Keep an audit trail of all reviews, change orders, and amendments—it simplifies compliance checks and future negotiations.

Set renewal triggers at least 60 days before the contract expires. This buffer lets you benchmark market rates and prepare a new draft without scrambling.

Finally, fold lessons learned into your next contract cycle. Institutional knowledge prevents repeated mistakes and sharpens accountability across all projects.

FAQ For Cable Contractor Companies

This section tackles the questions we hear most often about cable contractor firms, from their day-to-day duties to budgeting and risk management. Dive in to find practical advice and real-world tips.

What Do Cable Contractor Companies Do?

At their core, these firms handle everything from network design to final testing. They plan, install, and certify power, fiber, and data cables for energy sites, telecom networks, data centers—and then keep those systems running smoothly with ongoing maintenance.

How Long Does A Typical Cable Installation Project Take?

Generally, small-scale jobs wrap up in a few weeks. However, large builds can take several months—especially when permit approvals and weather conditions come into play.

Common Certifications

- ISO 9001: Validates a company’s quality management processes.

- NEBOSH: Demonstrates health and safety competence.

- IEC 61850: Sets standards for substation communication and automation.

- Local Safety Approvals: Ensures compliance with regional regulations.

How Do I Manage Unexpected Site Issues?

Begin with a thorough site survey and bake contingency clauses into your RFP. Pair that with a flexible change-order process, and you’ll be able to pivot quickly when surprises arise.

Key Tip: Early surveys and RFP contingencies can reduce project delays by 25%.

Which Pricing Models Are Common?

You’ll typically see two approaches:

- Unit-Rate Pricing: Pay for labor hours and materials as they’re used.

- Lump-Sum Bids: Agree on a fixed price that already includes contingency funds.

Choose the model that best suits your budgeting preferences and risk tolerance.

How Do Contractors Coordinate With Utilities?

Experienced contractors take charge of permit applications, schedule required outages, and keep utility partners in the loop. That proactive communication prevents service conflicts and keeps your timeline on track.

Ready to streamline your next cable project? Contact Southern Tier Resources for expert guidance.

Get started with confidence today.