Cell tower construction is the intricate process of taking an empty plot of land and transforming it into a crucial piece of our wireless communication network. It's a massive undertaking that pulls together disciplines ranging from civil engineering and structural design to sophisticated radio frequency technology.

The Blueprint for Modern Connectivity

Think of cell towers as the on-ramps and highways for our digital lives. Just like physical roads connect cities and towns, cell towers connect our phones, laptops, and smart devices to the global network. They make everything possible, from a simple phone call to streaming video or powering the Internet of Things (IoT). Each tower isn't just a random steel structure; it's a meticulously planned project, a single, vital piece in a much larger, interconnected puzzle.

This is about much more than just bolting steel together. It’s a carefully orchestrated mix of science, logistics, and highly skilled labor. The planning has to be precise, ensuring the final tower can stand up to high winds and harsh weather while delivering reliable service to potentially thousands of people. Long before any dirt is moved, every detail is mapped out, which is why understanding construction blueprints is so fundamental to the process.

From Concept to Concrete Reality

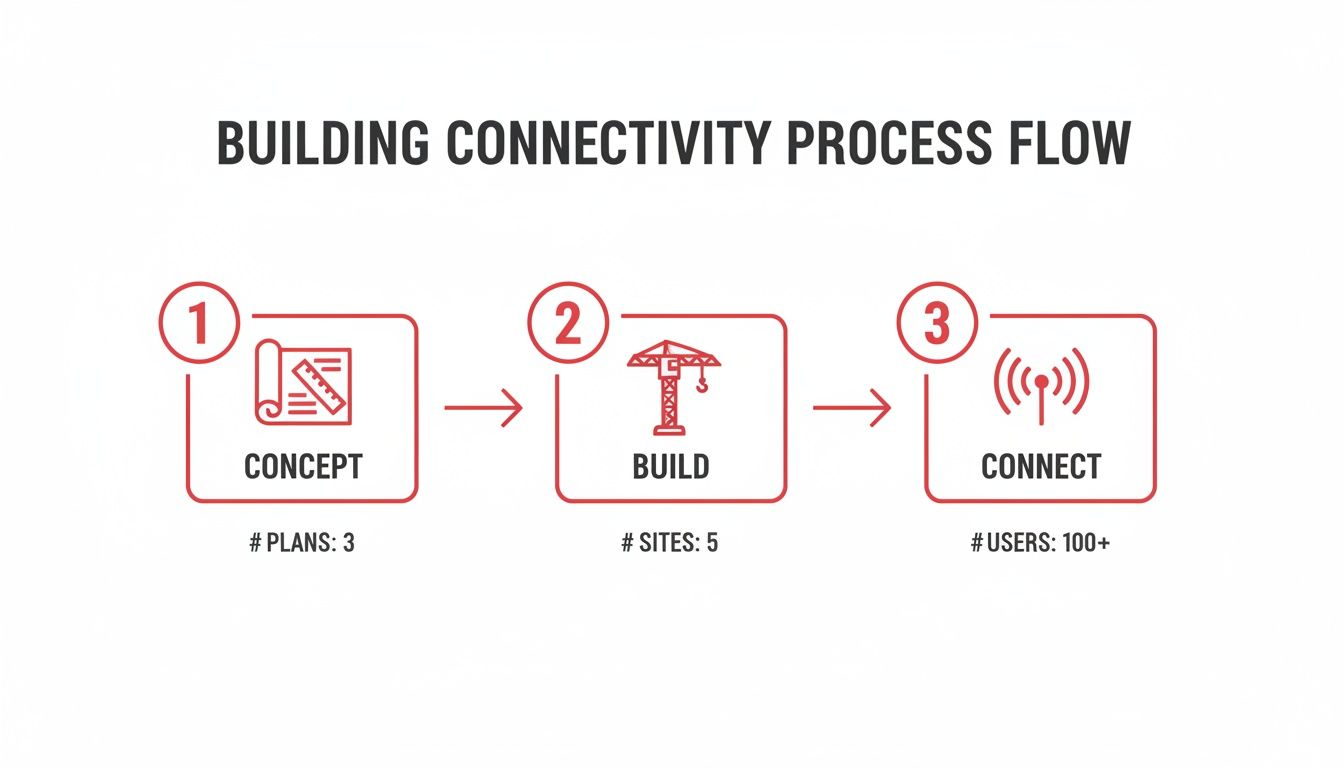

The journey of a cell tower starts well before the first shovel hits the ground. It begins with a need—a dead zone in a carrier's coverage map or an area where data demand is overwhelming the existing network. Once that need is identified, the project moves through a series of distinct phases, with each step building directly on the one before it, moving from an idea to a fully operational asset.

This guide will walk you through that entire lifecycle, breaking down the technical hurdles and logistical complexities you'll encounter along the way. We'll dig into the key stages that make or break a build:

- Site Acquisition and Permitting: This is ground zero. It’s all about finding the right piece of land and then navigating the often-tricky maze of local zoning laws and federal regulations.

- Engineering and Design: Here, network needs are translated into a structural design that is safe, effective, and meets all building codes.

- Foundation and Civil Work: This is where the real groundwork happens—preparing the site and pouring the massive concrete foundation that will anchor the entire tower. For a deeper dive into this critical phase, it helps to understand the fundamentals of https://southerntierresources.com/heavy-civil-construction/.

- Tower Erection and Integration: The most visible stage—the physical assembly of the tower and the installation of antennas, radios, and all the other telecom gear that makes it work.

The success of any cell tower project comes down to precision at every single step. A small mistake in the foundation can jeopardize the entire structure, just as a single delay in the permitting process can push a project's timeline back by months.

At the end of the day, building a cell tower is about forging connections. It’s an investment in the infrastructure that powers our modern economy, keeps our communities connected and safe, and ultimately, brings people closer. This guide gives you the roadmap to understand how it all comes together.

Navigating the Cell Tower Construction Lifecycle

Putting up a cell tower isn't a single project; it's a marathon of interconnected stages. Think of it like a relay race where each leg is handled by a different specialist, and a smooth handoff is critical to winning. From finding a tiny plot of land to lighting up a powerful signal, the entire process is a delicate balance of engineering, legal wrangling, and heavy construction.

Getting a handle on this progression is vital for anyone in the industry. It explains why timelines can stretch out unexpectedly and how a simple delay in one early phase, like getting a permit, can snowball, pushing back the entire schedule.

The journey from an idea on a map to a fully operational site follows a logical, if complex, path.

This visual breaks it down nicely: it all starts with the Concept (planning and design), moves into the Build (physical construction), and culminates in the Connect phase, where the tower joins the wider network.

To truly grasp what it takes to bring a cell tower to life, it helps to break down the lifecycle into its core phases. Each stage presents unique challenges and requires a specific set of skills to navigate successfully.

The table below outlines these key stages, giving you a quick look at the primary goal and the typical work involved in each one.

Key Phases of Cell Tower Construction

| Phase | Objective | Key Activities |

|---|---|---|

| 1. Site Acquisition & Leasing | Secure a suitable location for the tower. | RF analysis, landowner identification, lease negotiation, securing access rights. |

| 2. Zoning & Permitting | Obtain all necessary legal and regulatory approvals. | Submitting applications, attending public hearings, FAA/FCC compliance checks. |

| 3. Structural Engineering & Design | Create the technical blueprint for the tower. | Site surveys, geotechnical analysis, structural design, creating construction drawings. |

| 4. Civil Work & Foundation | Prepare the site and build the tower's anchor. | Land clearing, grading, access road construction, foundation excavation and concrete pour. |

| 5. Tower Erection & Installation | Assemble the tower structure and mount equipment. | Crane operation, steel assembly, antenna and radio installation, coaxial/fiber cabling. |

| 6. Power & Backhaul Integration | Connect the tower to utilities and the core network. | Commercial power hookup, backup generator/battery installation, fiber optic connection. |

Now, let's dig into what really happens at each of these critical junctures.

Phase 1: Site Acquisition and Leasing

It all starts with a fundamental question: where, exactly, are we going to build this thing? The Site Acquisition and Leasing (A&L) phase is ground zero. This is where teams work to pinpoint ideal locations based on radio frequency (RF) engineering studies that identify gaps in coverage or areas needing more capacity.

But it’s not as easy as planting a flag. The A&L specialists have to find property owners willing to lease a small slice of their land, often for 20 years or more. These negotiations are intense, covering everything from monthly rent and access rights to land use restrictions. It's a specialized form of real estate that demands both technical savvy and sharp people skills.

Phase 2: Zoning and Permitting

Once a lease is signed, the project moves into what is often the most frustrating and lengthy stage: Zoning and Permitting. This is where the plans meet the hard reality of local government and public opinion. Every town, county, and city has its own rulebook for what can be built, how high it can be, and what it should look like.

The gauntlet typically includes:

- Submitting Detailed Applications: Handing over a mountain of paperwork with comprehensive plans to local planning boards.

- Navigating Public Hearings: Standing before the community to justify the project and address concerns about everything from aesthetics to property values.

- Securing Federal Approvals: Getting the green light from agencies like the Federal Aviation Administration (FAA) for tower height and the Federal Communications Commission (FCC) for broadcasting.

It's a common myth that the actual construction takes the longest. The truth is, the legal and bureaucratic hurdles in the permitting phase can easily drag on for a year or more, far outlasting the physical build.

Phase 3: Structural Engineering and Design

With the necessary approvals secured, the engineers can finally roll up their sleeves. In the Structural Engineering and Design phase, the network's requirements are translated into a solid, buildable blueprint. The engineering team has to weigh several factors to choose the right kind of tower for the job.

The main options are:

- Monopole: A single, clean-looking pole. It's a favorite for tighter urban or suburban spots where aesthetics and a small footprint are key.

- Lattice Tower: The classic, self-supporting steel frame with three or four sides. These can handle a heavy load of equipment, making them a go-to in rural areas with more space.

- Guyed Tower: A slim mast held up by tensioned steel cables anchored to the ground. This design can reach impressive heights for less material cost but needs a huge amount of land.

The final design is meticulously calculated to handle local wind loads, ground conditions, and the combined weight of all the antennas and gear it will eventually hold.

Phase 4: Civil Work and Foundation Construction

This is where dirt finally starts to move. Civil Work marks the beginning of physical construction, starting with preparing the site. Crews clear the land, grade it for proper drainage, and often build an access road capable of handling heavy machinery. The star of this show, however, is the foundation.

A cell tower's foundation is a massive, precisely engineered block of steel-reinforced concrete buried deep underground. It’s the anchor that keeps the structure stable against high winds and anything else nature throws at it. Geotechnical engineers determine its exact size and depth based on soil tests to ensure it can support the tower for decades to come.

Phase 5: Tower Erection and Antenna Installation

Once the foundation concrete has cured, the most dramatic part of the build begins: Tower Erection. Using massive cranes, crews hoist and bolt together the tower section by section. It’s a job that requires incredible precision and an unwavering focus on safety, with teams working hundreds of feet in the air.

After the steel is up, specialized rigging crews climb the structure for the Antenna and Line Installation. They mount the antennas, radios, and other RF gear at the exact heights and angles specified in the engineering designs—a crucial step for creating the planned coverage pattern. This kind of work is fueling a massive industry; the global telecom tower market was valued at around $80 billion in 2024 and is projected to soar to $150 billion by 2030. You can find more details on this explosive growth and its drivers at researchandmarkets.com.

Phase 6: Power and Backhaul Integration

A steel tower is just a landmark until it gets power and a data connection. The Power and Backhaul Integration phase is what brings the site online. This involves trenching in commercial electricity and installing backup systems—usually a large generator or banks of batteries—to keep the site running during a power outage.

At the same time, the "backhaul" is connected. This is the site's data pipeline to the outside world, usually a high-capacity fiber optic cable that links the tower to the carrier's main network. With power and data flowing, the site is ready to be tested and commissioned, officially transforming it from a piece of steel into a vital node in our communication network.

Understanding Tower Development Costs and Timelines

When you're planning to build a cell tower, it's a bit like planning a cross-country expedition. You can't just focus on the final destination; you have to meticulously map out every leg of the journey, from fuel costs and supply stops to potential detours and bad weather. The final budget and schedule for a tower are shaped by dozens of variables that can change dramatically from one site to the next.

A common assumption is that the steel tower itself is the biggest line item. While it's certainly a major expense, it's just one piece of a much larger and more complex financial puzzle. To plan and execute a project successfully, you need a firm grasp on the full scope of costs and time commitments involved.

Decoding the Primary Cost Drivers

The all-in investment for a single macro tower can easily land anywhere between $150,000 to over $500,000, sometimes even more if the site presents unique challenges. This isn't a single lump sum but a collection of costs spread across several critical areas, each with its own factors that can make the budget balloon.

Let’s break down where the money really goes:

- Site Acquisition and Leasing: This isn't just about the monthly check to the landowner. It includes the often hefty legal fees for negotiating contracts and the costs of navigating zoning hearings.

- Permitting and Regulatory Fees: Getting the green light involves paying a host of fees to local municipalities, counties, and even federal bodies like the FAA for applications, inspections, and approvals. These can really add up.

- Materials and Equipment: Beyond the raw steel and concrete, whose prices can fluctuate with the market, you have substantial capital tied up in specialized antennas, radios, and crucial backup power systems.

- Labor and Construction: This is a big one. It covers everything from civil engineers and foundation crews to crane operators, tower climbers, and licensed electricians. Specialized skills come at a premium.

With so many parts and pieces to track, using specialized tools like construction inventory software has become essential. It helps keep operations tight and costs in check by ensuring you don't face expensive delays because a critical component is missing.

Navigating the Unpredictable Timelines

Here's the part that catches many people by surprise: the physical construction of a tower is actually quite fast, often taking just four to eight weeks. The real test of patience happens long before the first shovel hits the ground.

The permitting and zoning approval process is, without a doubt, the number one reason for project delays. What looks like a straightforward six-month approval can get snarled in local politics or community opposition, stretching the timeline out to a year or more.

This is where having an experienced partner who provides full-service https://southerntierresources.com/telecom-construction-services/ can be a game-changer. They've seen these roadblocks before and know how to navigate them.

Here's how a typical project timeline unfolds:

- Site Acquisition & Leasing (2-6 months): Finding the right spot with a willing landowner and hammering out a solid lease agreement takes time and careful negotiation.

- Zoning & Permitting (6-24+ months): This is the wild card. It's a marathon of detailed applications, public hearings, and securing approvals from multiple government agencies.

- Engineering & Design (1-3 months): Once the permits are in hand, engineers can finalize the structural blueprints and construction plans.

- Construction & Integration (2-4 months): This is the final sprint. From pouring the foundation and erecting the steel to commissioning the site, this is where the physical work gets done.

Ultimately, getting a cell tower from concept to reality demands a clear-eyed view of both the financial investment and the timeline. By understanding what drives costs and delays, carriers and tower companies can set more realistic expectations, create smarter budgets, and be better prepared for the road ahead.

Mastering the Regulatory and Permitting Maze

Building a cell tower is one part construction and nine parts navigating a dense web of rules, regulations, and public opinion. In my experience, the regulatory and permitting phase is almost always the longest and most unpredictable part of the entire lifecycle.

A simple misstep here can stall a project for months, creating costly delays before a single shovel of dirt is ever turned. Success requires a multi-layered approach, satisfying everyone from federal agencies to local community boards. Each group has its own concerns, from national airspace safety down to the aesthetic impact on a single neighborhood.

Understanding Federal Oversight

At the top of the pyramid, a couple of key federal agencies have jurisdiction over every single tower build. Their approval is absolutely non-negotiable and sets the stage for everything that follows.

-

Federal Communications Commission (FCC): The FCC is the gatekeeper of the nation's airwaves. They make sure a new tower’s broadcast frequencies won’t interfere with existing signals and that the project complies with all federal telecom laws.

-

Federal Aviation Administration (FAA): The FAA's job is to keep the skies safe. They review any proposed tower to ensure it won’t pose a hazard to aircraft, which means scrutinizing its height, location, and lighting requirements. Getting a "No Hazard Determination" from the FAA is a critical milestone.

On top of that, every project must clear the National Environmental Policy Act (NEPA). This involves an assessment to prove the construction won't harm environmentally sensitive areas, disturb historical sites, or threaten endangered species.

Navigating Local Zoning and Community Hurdles

While federal approval is a must-have, the real battles are often fought at the local level. This is where a project can easily get bogged down in municipal codes, public hearings, and fierce community opposition.

Every town and county has its own rulebook for land use, known as zoning laws. These codes dictate everything from how tall a tower can be to how far it must be set back from property lines. Getting a zoning variance or a special use permit almost always means a public hearing, where local residents can voice their support or, more often, their objections.

A project's success often comes down to genuine community engagement. You have to anticipate objections over aesthetics and perceived impacts on property values. The best teams address these concerns head-on with clear data, visual simulations, and a real willingness to find common ground.

Here are the challenges we see time and time again:

-

Aesthetic Objections: Let's be honest, most people don't want to look at a traditional lattice or monopole tower. This has given rise to creative "stealth towers," cleverly disguised as everything from pine trees and flagpoles to church steeples.

-

Building Code Compliance: The tower's design, especially its foundation, has to meet incredibly strict local building codes for structural integrity, wind load resistance, and overall safety.

-

Public Hearings: Standing in front of a skeptical planning board or a room full of concerned residents is daunting. It requires a team that can clearly explain why the tower is needed and present compelling evidence of its minimal impact.

Making it through this maze requires more than just filling out paperwork. It takes a deep understanding of the legal landscape and a smart approach to communication. Meticulous applications, proactive community outreach, and expert legal guidance are what turn a promising site into a fully approved project, finally clearing the way for construction to begin.

Key Trends Shaping Modern Tower Construction

The world of cell tower construction isn't static. It's constantly adapting to the needs of a society that demands more data and better connectivity. The biggest driver of this change? The rollout of 5G, which is completely reshaping how we design and build networks. It’s not just about erecting another tall tower in a field anymore.

The reality of 5G is a strategy called network densification. This means deploying a dense web of smaller, localized cell sites—often called small cells—especially in cities, to work alongside traditional macro towers. This hybrid approach is the only way to deliver the blistering speeds and near-zero lag that 5G promises. For construction partners, this requires a dual expertise in both massive structures and compact, discreet installations.

The Shift to Multi-Purpose Infrastructure

Towers today are being asked to pull double, even triple, duty. They're evolving from simple signal transmitters into versatile digital hubs that power a whole host of services. This trend demands a forward-thinking approach to construction, engineering structures from day one to be adaptable and ready for future upgrades.

This new generation of infrastructure is built to support a lot more than your phone:

- Internet of Things (IoT) Devices: Towers are the central nervous system for smart cities, connecting everything from traffic sensors and agricultural monitors to industrial automation equipment.

- Edge Computing: By placing small data processing units right on the tower, operators can dramatically cut down on latency. This is critical for applications like autonomous vehicles and real-time analytics where every millisecond counts.

- Public Safety Communications: Many new towers now host dedicated equipment for police, fire, and other first responder networks, guaranteeing they have a reliable line of communication when it matters most.

Bringing all these technologies together means modern tower designs must handle more equipment, consume more power, and integrate more complex fiber connections than ever before. Understanding the role of modern tech in construction is key to seeing how these complex integrations happen on the ground.

Sustainability and Efficiency in Construction

As the demand for new towers explodes, so does the pressure to build them responsibly. The industry is making a real push toward greener construction methods and more energy-efficient operations. This isn't just about environmental stewardship; it's a smart business move that leads to major long-term savings on operational costs.

Building for the future means more than just meeting today's technical specifications. It means constructing infrastructure that is environmentally responsible, community-friendly, and economically viable for decades to come.

We're seeing some genuinely smart innovations in this area. Advanced, lighter composite materials are reducing the carbon footprint of the build process itself. Modular tower designs are also becoming popular because they allow for faster, more efficient deployment with far less on-site waste. And, of course, integrating renewable power like solar panels and wind turbines is becoming standard practice, especially for remote towers located off the main power grid.

This market is absolutely booming, with projections showing it will grow from $94.389 billion in 2025 to $125.127 billion by 2030. This growth is fueled by these very trends, including the push for flexible, multi-use tower designs and even aesthetically pleasing structures that blend seamlessly into cityscapes. As you can discover more insights about the telecom tower market growth, it's clear these forward-looking practices aren't just a niche—they are the future of wireless connectivity.

Driving Success with Project Management and Quality Assurance

A cell tower project is far more than just steel and concrete. It’s a complex logistical puzzle where every piece—from timelines to budgets to safety standards—must fit together perfectly. Think of project management as the central nervous system of the entire operation; it’s what turns a well-designed plan into a tangible, functioning asset.

Without that disciplined oversight, things can go wrong fast. A missed deadline or a budget oversight can have a domino effect, leading to costly delays and, even worse, serious safety risks. The foundation of good management here is relentless communication and meticulous record-keeping. Every step, from daily progress reports to the final "as-built" drawings, gets documented. This not only keeps everyone accountable but also creates a vital historical record for future maintenance and upgrades.

Prioritizing a Safety-First Culture

Let's be clear: in an industry that involves heavy machinery, high-voltage electricity, and working at serious heights, safety isn't just a priority. It's everything. Building a "safety-first" culture is non-negotiable, meaning every single person on site, from the project manager to the newest tower tech, is empowered to speak up and expected to follow safety protocols without fail.

This goes way beyond just checking a box. It's a commitment that shows up in daily actions:

- Rigorous OSHA Adherence: All work must strictly follow Occupational Safety and Health Administration regulations, especially for fall protection, crane operations, and electrical safety.

- Daily Safety Briefings: Every day starts with a "tailgate" meeting. The crew huddles up to discuss the day's tasks, pinpoint potential hazards, and review the safety plan one more time.

- Continuous Training: Crews need to be more than just experienced; they must be certified. Regular training in tower rescue, first aid, and specific equipment handling is essential.

Measuring Success with Key Performance Indicators

You can't manage what you don't measure. To keep a project this complex from veering off course, carriers and their construction partners lean heavily on Key Performance Indicators (KPIs). These are the hard numbers that give a clear, unbiased picture of how the project is actually doing, helping teams spot trouble long before it snowballs.

Ultimately, a project is successful if it delivers a high-quality, reliable network asset on time and on budget. Strong project management and an unwavering focus on quality are what make that happen consistently.

A few of the most common KPIs include:

- Permitting Cycle Time: How long is it really taking to get all the necessary zoning and building permits? This is often a major bottleneck.

- Budget Variance: Are we spending what we planned to spend? Tracking actuals against the budget in real-time is crucial for preventing cost overruns.

- Construction Schedule Adherence: How does our actual progress stack up against the project timeline? This simple metric tells you if you're on track to hit your milestones.

This data-driven approach is absolutely critical when you're talking about large-scale network deployments. Operators are in a constant race to build out their infrastructure. Just look at the scale of China Tower, which was managing 2.12 million towers as of June 2025, with an average of 1.81 tenants per tower. You can read the full report on China Tower's H1 performance to grasp the magnitude of these operations. Numbers like these make it obvious why disciplined, efficient project management isn't just a good idea—it's the only way to succeed.

Common Questions About Cell Tower Construction

Even with a solid grasp of the project lifecycle, people still have plenty of practical questions about how a cell tower actually goes from an idea to a structure in the ground. Getting straight answers to these common queries helps demystify the process for landowners, community members, and even folks new to the industry.

Let's dive into some of the most frequently asked questions we hear.

How Long Does It Take to Build a Cell Tower?

This is probably the most common question, and the answer can be surprising. The total project timeline, from a handshake deal to a fully operational site, can run anywhere from six months to over two years.

The real bottleneck isn't the physical build—it’s everything that comes before it. The pre-construction phase is almost always the longest and most unpredictable part. We're talking about site acquisition, lease negotiations, contentious local zoning hearings, and securing a mountain of permits. This paperwork and approval process can easily eat up a year or more, especially if there's community pushback or environmental hurdles.

Once all the approvals are finally in hand, the on-site construction is a sprint. From pouring the foundation to stacking the steel, the tower itself is typically up in just four to eight weeks.

What Are the Main Types of Cell Towers?

While you'll see plenty of unique designs, most of the big "macro" cell towers fall into one of three main categories. Each one is a tool for a specific job and environment.

- Monopoles: These are the sleek, single-pole structures you often see in cities and suburbs. Their clean look makes them a popular choice where space is tight and aesthetics are a concern.

- Lattice Towers: Think of the classic, self-supporting steel frameworks with three or four sides. These are the workhorses of the industry—incredibly strong and able to hold a ton of equipment. You'll find them mostly in rural areas where they have room to spread out.

- Guyed Towers: This design uses a very slender mast held upright by tensioned steel cables anchored to the ground. They're a cost-effective way to get serious height but require a massive land footprint for all those guy wires.

A common misconception is that carriers like Verizon or AT&T own most towers. In reality, a huge percentage are owned and managed by specialized tower companies, who then lease space on the structure to multiple wireless carriers.

Who Handles Maintenance After Construction?

It all comes down to who owns the steel. If a wireless carrier builds and owns the tower outright, their in-house teams handle all the maintenance.

But more often than not, the tower is owned by a third-party tower company. In that common scenario, the tower owner is responsible for the physical structure itself—the foundation, the steel, and the fenced-in compound. The individual carriers who are tenants on that tower are then responsible for maintaining their own gear, like antennas, radios, and fiber optic lines.

What Is a Turnkey Construction Partner?

A turnkey construction partner is essentially a "one-stop shop" that manages every single phase of a cell tower project, from start to finish. They handle the entire lifecycle for you.

Their scope covers site acquisition, engineering, navigating the regulatory maze, all the civil work, erecting the tower, and getting the site tested and on the air. Working with a turnkey provider simplifies a massively complex process down to a single point of contact. It cuts down the administrative headache for the client and helps ensure the project gets delivered smoothly and efficiently.

At Southern Tier Resources, we specialize in providing these exact end-to-end turnkey solutions for wireless network infrastructure. Our teams manage every detail, from the initial design sketches to the final commissioning tests. With our experience, you can be confident your cell tower construction project is completed safely, on schedule, and to the highest industry standards. Find out how we can be your single accountable partner by visiting us at https://southerntierresources.com.