Corning fiber is, quite literally, the backbone of our connected world. It's the high-speed nervous system that carries data across the globe, a specialized glass filament thinner than a human hair that powers everything from 5G and cloud computing to the AI revolution. All the massive, near-instantaneous data flows that define modern life depend on it.

The Role of Corning Fiber in Our Digital World

Think of the global digital economy as a complex organism. Data centers are the brain, and our devices are the limbs. The fiber optic network is the central nervous system connecting them all, carrying critical information at the speed of light. In this system, Corning fiber is the high-performance nerve cell—the fundamental component that makes everything work.

Without this incredible infrastructure, the services we take for granted would grind to a halt. Streaming video, cloud storage, real-time collaboration, and the massive computational power needed for artificial intelligence all rely on the incredible bandwidth and low latency that only fiber optics can deliver.

Pioneering Global Connectivity

Corning isn't just a player in this space; they are a true pioneer. They invented the first low-loss optical fiber back in 1970, a breakthrough that kicked off the modern telecommunications era. That legacy of innovation is more important than ever as networks constantly evolve to handle exponential increases in data traffic.

As a global leader, Corning is at the heart of the expansion of 5G, broadband, and data centers. With around 57,500 employees and generating about $14 billion in revenue in recent years, their impact is undeniable. You can learn more about the growing fiber optics market, where demands for high-speed internet continue to drive significant growth.

Choosing the right technology is only half the battle. The quality of its deployment determines whether a network achieves its full potential or suffers from performance issues and costly downtime.

From Materials to Mission-Critical Networks

While the quality of Corning fiber is world-class, its true potential is only unlocked through expert installation and network design. A state-of-the-art cable is just a spool of glass if it's handled improperly, spliced poorly, or tested inadequately. This is where a skilled partner makes all the difference.

At Southern Tier Resources, we specialize in transforming these exceptional materials into reliable, turnkey network solutions. Our team's expertise ensures that every single strand of Corning fiber is deployed to meet the most demanding performance standards. This meticulous approach guarantees that the digital nervous system we build for our clients is robust, scalable, and ready for whatever the future holds. To learn more about related technologies, check out our guide on internet infrastructure.

Understanding Single-Mode and Multimode Fiber

When you're designing a fiber optic network, one of the first and most important decisions is choosing between single-mode and multimode cable. They both use light to move data through a glass core, but how they do it is worlds apart. Getting this choice right from the start is absolutely critical for building a network that’s not just efficient and cost-effective today, but also ready for whatever comes next.

The real difference boils down to the diameter of the fiber's core. Single-mode fiber has a core that's almost unbelievably small—typically just 9 microns (µm). To put that in perspective, that’s thinner than a human hair. This tiny channel forces light to travel in a single, straight path, or "mode."

On the other hand, multimode fiber has a much larger core, usually 50 µm or 62.5 µm. Think of it as a wider highway that allows multiple paths of light to bounce along inside it at the same time. This one structural difference dictates everything that follows, from performance and distance limitations to the best places to use each type.

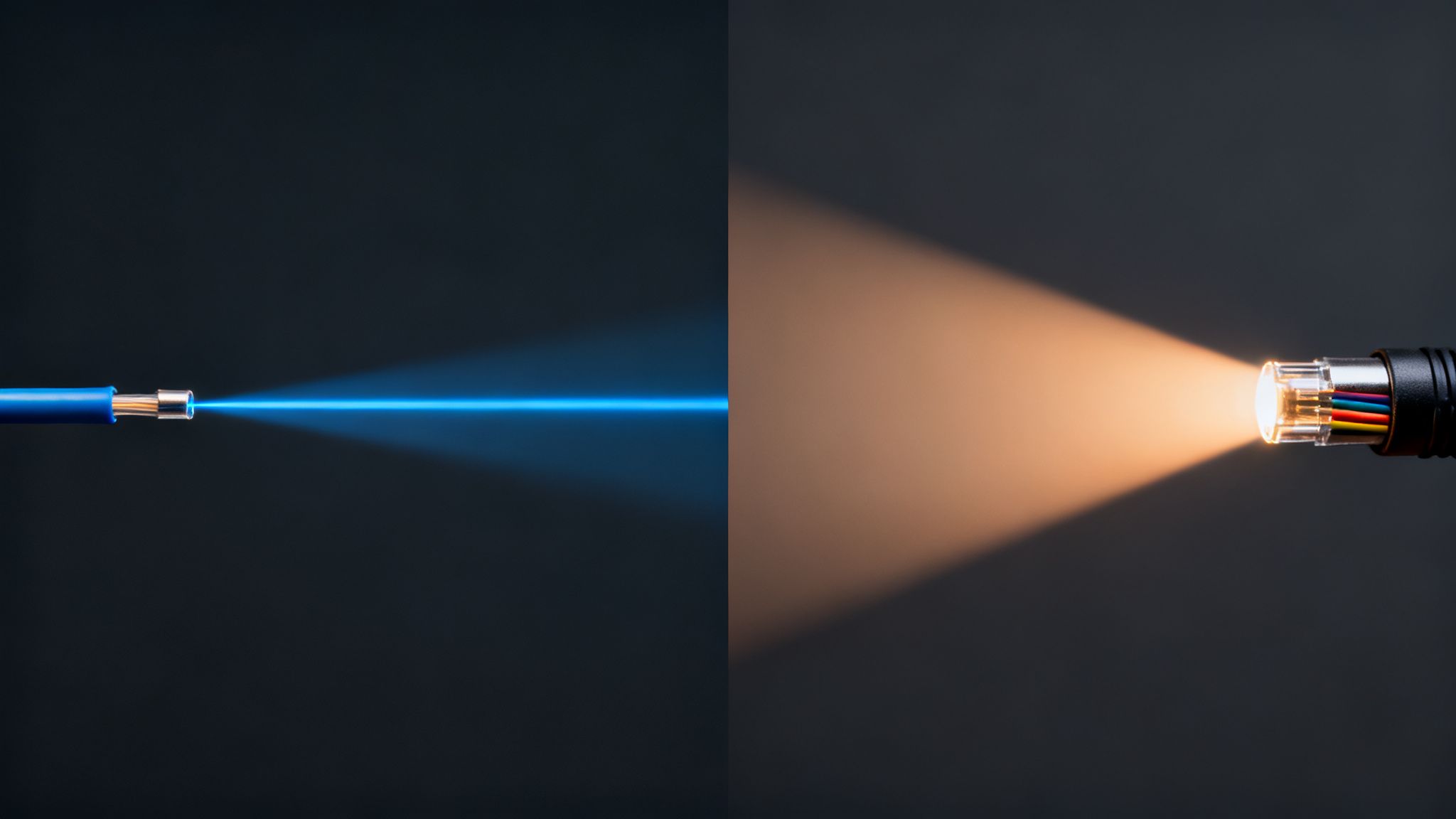

The Laser Beam vs. The Flashlight

A simple way to think about this is to compare the two to different kinds of light beams.

Single-mode fiber is like a laser beam. It's a focused, powerful, and straight line of light that can travel for miles and miles without losing its integrity. This is why it’s the undisputed king of long-haul, high-bandwidth networks.

Multimode fiber is more like a flashlight. The light spreads out, illuminating a wider area but losing its intensity much faster. This makes it a great, practical choice for shorter runs, like wiring up an office building or connecting buildings across a campus.

This difference in how light travels has a direct impact on signal quality. With multimode fiber, because you have all these different light paths bouncing around, they can arrive at the other end at slightly different times. This effect, known as modal dispersion, is what limits the cable’s effective range and bandwidth. Since single-mode fiber only has one path, it doesn't have this problem, which is why it can carry so much more data over such incredible distances.

To put the key differences side-by-side, here’s a quick breakdown of how these two fiber types stack up against each other.

Corning Single-Mode vs Multimode Fiber At a Glance

| Attribute | Single-Mode Fiber (SMF) | Multimode Fiber (MMF) |

|---|---|---|

| Core Diameter | Very small (9 µm) | Larger (50 µm or 62.5 µm) |

| Light Path | One direct path | Multiple bouncing paths |

| Light Source | Lasers (more expensive) | LEDs or VCSELs (less expensive) |

| Max Distance | 100+ km | Up to ~550 meters |

| Bandwidth | Virtually unlimited | Limited by modal dispersion |

| Primary Cost | Higher equipment/transceiver cost | Lower equipment/transceiver cost |

| Ideal Use Case | Long-haul, metro, carrier networks | Data centers, LANs, campus networks |

This table shows the clear trade-offs: single-mode gives you incredible distance and capacity but costs more for the electronics, while multimode is the go-to for affordable, high-speed connections over shorter distances.

Exploring Corning's Single-Mode Solutions

When you need to connect cities, states, or even continents, there's no substitute for single-mode fiber. Corning's single-mode products are the backbone of the global internet, trusted by telecom carriers and massive cloud providers for their reach and reliability.

Some of their standout single-mode products include:

- G.652.D Fiber: This is the workhorse of the industry. It's the most common single-mode fiber deployed around the world, engineered to work perfectly across the standard wavelengths used in modern networks.

- G.657 Fiber: This is a more specialized, bend-insensitive fiber, part of Corning’s innovative ClearCurve lineup. It’s designed to be bent and routed in tight spaces—like crowded data center conduits or in-home FTTH drops—without significant signal loss.

The laser-based optics required for single-mode systems are more expensive, but that initial investment is easily justified by performance that spans hundreds of kilometers without needing a repeater.

Multimode Fiber for Shorter Distances

When your network lives within a single building or campus, multimode fiber is almost always the more practical and economical choice. Its larger core works perfectly with less expensive light sources, like LEDs and VCSELs (vertical-cavity surface-emitting lasers), which brings down the total cost of ownership.

Corning’s multimode family is identified by the "OM" (Optical Multimode) classification, and each new generation pushes the boundaries of speed and performance:

- OM3 and OM4 Fiber: These are laser-optimized multimode fibers (LOMMF) and are the bread and butter of modern data centers. They reliably support speeds of 10 Gbps and even 40/100 Gbps over a few hundred meters.

- OM5 Fiber: Also called wideband multimode fiber, OM5 is designed for the future. It supports a technology called short-wavelength division multiplexing (SWDM), which lets you send multiple data streams over a single fiber, dramatically increasing density for next-generation data centers.

In the end, choosing the right Corning fiber is a strategic decision. You're balancing the near-limitless bandwidth and extreme distance of single-mode against the cost-effective, high-speed performance of multimode for localized networks.

Taming the Bends: How ClearCurve Fiber Changed the Game

Anyone who has worked with traditional fiber optic cables knows their biggest weakness: they hate being bent. Force a standard cable around a sharp corner or pull it through a tight space, and the light signal carrying your data can literally leak out. This signal leakage, known as macrobending loss, has been a constant source of frustration for installers, causing failed connections and hours of rework.

This is where Corning’s ClearCurve fiber really shines. It’s not just a small tweak to an old design; it’s a complete re-think of how fiber optic cable can handle the real-world pressures of installation, where clean, straight runs are rarely the reality.

Think of the light traveling down the fiber core like water flowing through a pipe. In a standard fiber, a sharp bend is like a crack in that pipe—water spills out, and pressure drops. ClearCurve adds a nearly invisible feature to the fiber: a nano-scale optical "trench" that acts like a guardrail around the core.

This ingenious design works like a mirror, reflecting any light that tries to escape during a bend right back into the core. It effectively keeps the signal contained, ensuring it reaches its destination with full strength, even when the cable is stapled around a 90-degree corner.

For technicians in the field, this technology is a massive relief. It dramatically lowers the risk of signal loss caused by everyday handling, routing, and even storage, making installations faster and far more reliable.

Where ClearCurve Makes a Real Difference

The beauty of ClearCurve is how it solves practical problems across the board, whether you're working with single-mode or multimode fiber. It gives installers the confidence to work in tight, complex spaces without constantly worrying about damaging the connection.

- Data Centers: In the packed environment of server racks and cable trays, ClearCurve OM3, OM4, and OM5 fibers can be woven around hardware and through congested pathways without signal degradation. This makes higher-density setups possible and simplifies cable management immensely.

- Apartment & Office Buildings (MDUs): Getting fiber into multi-dwelling units means dealing with sharp turns inside walls, risers, and utility closets. The incredible flexibility of ClearCurve G.657 fiber is practically a requirement for these jobs.

- Fiber-to-the-Home (FTTH): When running fiber to a customer's house, technicians encounter tight bends everywhere—around building foundations, inside wall jacks, and within small demarcation boxes. ClearCurve ensures these final-mile connections are durable and dependable.

More Than Just Flexibility

Beyond its impressive bend performance, Corning fiber delivers major operational wins. It offers up to 54% lower energy consumption compared to copper, is completely immune to electromagnetic interference (EMI), and provides a clear path for future bandwidth upgrades. These attributes make it a cornerstone of the end-to-end services we deliver at Southern Tier Resources, from initial network design to final testing and maintenance.

The development of ClearCurve technology has fundamentally changed the cost-benefit analysis of fiber installation. By virtually eliminating macrobending loss as a common point of failure, it allows for quicker deployments with less need for painstaking, delicate handling. This translates directly into lower labor costs and faster project completion times. You can see how this pairs with other modern installation methods in our guide on directional drilling for fiber optics.

At the end of the day, ClearCurve is a perfect example of Corning solving a real-world problem for the people in the field. It takes fiber from being a fragile, sensitive material to a tough, forgiving solution that can be installed just about anywhere. It ensures the network you build is just as powerful in reality as it was on the blueprint.

Choosing the Right Corning Fiber for Your Application

Picking the right optical fiber is one of the most critical decisions you'll make when designing a network. It's not just about selecting a cable; it’s about matching the physical medium to the specific, real-world demands of its environment. When you choose the correct Corning fiber, you're building a network that will hit its performance targets today and still have the headroom to handle future growth without a costly rip-and-replace.

Think of it like choosing the right engine for a vehicle. You wouldn’t put a small, four-cylinder engine in a semi-truck expected to haul freight cross-country. Likewise, you wouldn't install a massive diesel engine in a compact city car. Each job has unique requirements for power, efficiency, and range—and the exact same logic applies to fiber optics.

For Transcontinental and Metro Networks

When your data has to cross hundreds or even thousands of kilometers between cities, single-mode fiber is the only game in town. In these long-haul and metropolitan networks, the undisputed workhorse is Corning’s SMF-28® Ultra fiber, a product that fully complies with the ITU-T G.652.D standard.

This fiber is engineered for one primary purpose: sending a clean, powerful signal over immense distances with the least possible signal degradation. Its low-loss characteristics are crucial for minimizing the number of expensive amplifiers and repeaters needed along a route, which translates directly into lower capital and operational costs for network operators.

- Key Requirement: Maximum reach and minimal signal loss.

- Corning Solution: SMF-28® Ultra fiber (G.652.D) is the industry standard for these deployments, trusted by carriers all over the world.

- Why It Works: It's fine-tuned for the specific wavelengths used in long-haul transmission, ensuring rock-solid reliability for the internet's core backbone.

High-Speed Data Center Interconnects

The modern data center is an ecosystem of blistering speed and incredible density. The challenge here is different; distances are much shorter, but the thirst for massive bandwidth is practically unquenchable. This is the domain of laser-optimized multimode fiber (LOMMF), specifically Corning's ClearCurve® OM4 and OM5 fibers.

These fibers are built to support staggering data rates—100 Gbps, 400 Gbps, and beyond—over the shorter distances you find within and between data center buildings. OM5, also known as wideband multimode fiber, takes this a step further. It enables wavelength division multiplexing (WDM) technologies, which allow multiple data streams to travel over a single fiber strand, dramatically increasing network capacity without having to pull more cable.

The recent explosion in AI infrastructure has ignited incredible demand for this type of high-speed connectivity. In fact, Corning's enterprise network sales recently shot up an amazing 81% in a single quarter, a surge driven by the urgent need to build robust, low-latency networks for AI data centers. You can discover more insights about enterprise demand for high-speed fiber connectivity to see this trend in action.

Last-Mile and Fiber to the Home (FTTH)

Connecting individual homes and businesses—the "last mile"—presents its own unique set of installation headaches. Technicians have to navigate tight corners, jam-packed utility closets, and sharp bends inside walls. In these scenarios, bend performance is everything.

This is exactly where Corning's ClearCurve G.657 single-mode fiber shines. It’s engineered to be bent, stapled, and coiled in tight spaces without the crippling signal loss that would bring a standard fiber to its knees. This flexibility makes installations faster, simpler, and far more reliable, which means fewer service calls and happier customers who get a strong, consistent connection from day one.

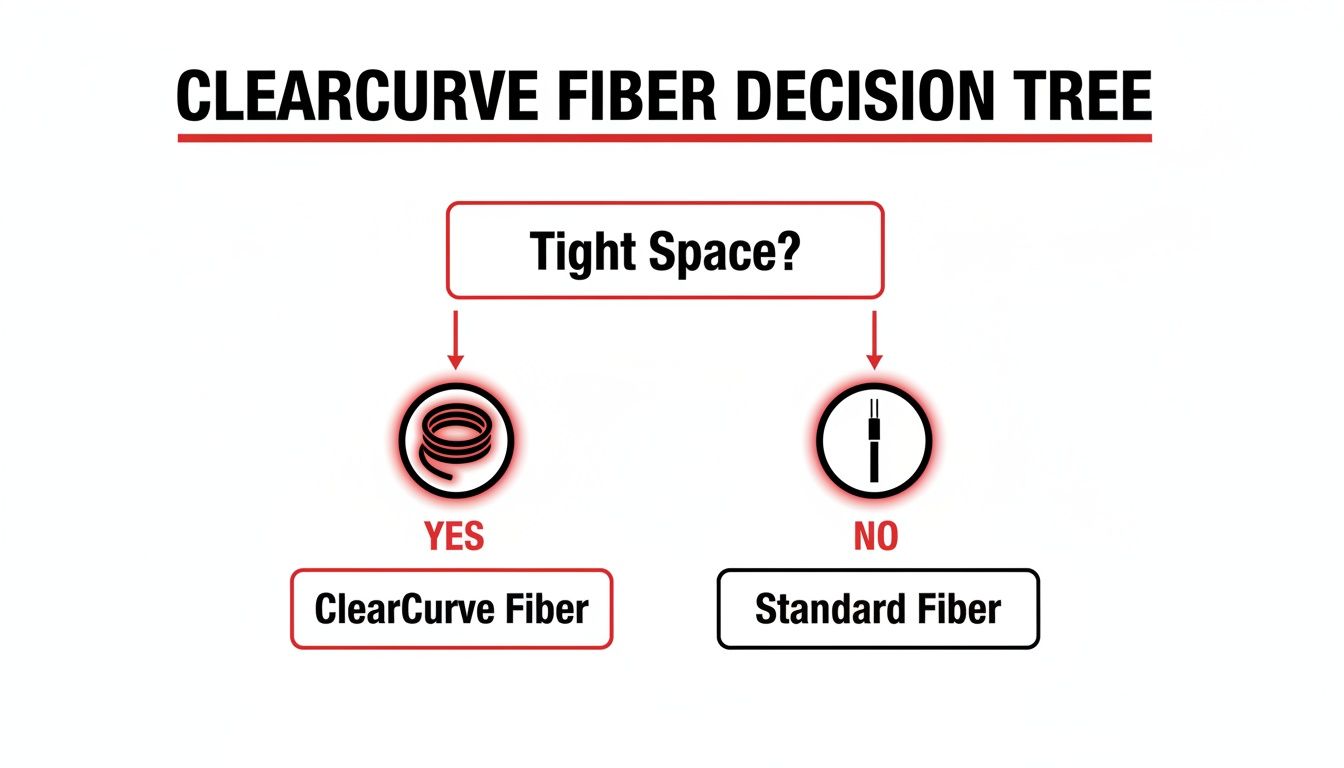

This decision tree gives you a simple way to think about when ClearCurve is the right tool for the job.

As you can see, if an installation involves wrestling with tight spaces or sharp bends, the bend-insensitive properties of ClearCurve are absolutely essential for a successful outcome.

Enterprise and Campus Backbones

For connecting buildings across a corporate or university campus, network designers have to strike a smart balance between current needs, future scalability, and the budget. The choice often boils down to either single-mode or a high-performance multimode fiber.

Decision Point: A key factor here is distance. If your buildings are separated by more than 500 meters, single-mode fiber is almost always the more reliable and future-proof choice. For shorter runs, multimode (like OM4) can be a more cost-effective solution because the transceivers are less expensive.

By carefully matching the technical capabilities of a specific Corning fiber to the application's real-world demands, you create a network foundation that is both high-performing and economically sound for the long haul.

Best Practices for Handling and Installing Corning Fiber

Building a network with premium Corning fiber is only half the battle. The real test comes during installation. Even the most advanced fiber in the world won’t perform as expected if it's handled improperly. Following field-proven best practices is the only way to make sure the finished network delivers on its promise of speed and reliability for decades to come.

Think of it like a high-performance engine; the quality of the parts matters, but so does the skill of the mechanic who assembles it. Our teams at Southern Tier Resources treat every installation with that level of precision, turning top-tier materials into a robust asset that’s built to last.

Mastering Bend Radius and Pulling Tension

Two of the easiest—and most damaging—mistakes an installer can make involve bend radius and pulling tension. Every fiber cable has a strict limit on how tightly it can be bent before the delicate glass core is stressed. Push it too far, and you can create microfractures that cripple the signal or cause total failure.

Respecting the bend radius isn't a suggestion; it's a fundamental rule of fiber installation. Exceeding it, even briefly, can introduce permanent signal loss that is incredibly difficult to locate and repair after the fact.

The same goes for pulling force. Yanking a cable with too much tension can stretch and break the fibers inside the protective jacket. It’s absolutely essential to use the right tools—like pulling grips, lubricants, and tension monitors—to stay well within the manufacturer’s specified limits.

- Always check the datasheet: Every Corning fiber cable has a specific bend radius and tension limit. These numbers are non-negotiable.

- Use professional tools: Capstans and breakaway swivels help ensure the pulling force stays consistent and safely below the maximum rating.

- Walk the route first: Before any pull starts, survey the entire pathway to spot potential snag points or sharp turns that could damage the cable.

The Critical Importance of Connector Cleaning

It might sound simple, but a huge number of network failures trace back to one culprit: dirty connectors. A single microscopic speck of dust or a smudge from a fingerprint on a connector end-face is enough to block the light signal, causing high loss and terrible performance.

This is why a strict "inspect and clean" protocol is a non-negotiable part of every professional installation. Before any two fibers are connected, both ends must be inspected with a specialized fiberscope. If there's any contamination at all, it has to be cleaned off with approved tools and solvents. Check out our in-depth guide on fiberscope inspection to see just how vital this process is.

Managing Environmental Factors for OSP and ISP

Where you install the fiber completely changes the game. The challenges of an outside plant (OSP) run are world's apart from an inside plant (ISP) deployment in a building.

Outside Plant (OSP) Considerations:

- Temperature Swings: Cables have to be rated to handle blistering heat and freezing cold without degrading.

- Moisture Ingress: Splice closures and termination points must be perfectly sealed to keep water out. Nothing kills a fiber link faster than moisture.

- Physical Threats: Underground fiber needs ruggedized duct or direct-burial cable, while aerial fiber has to be tensioned just right to handle wind, ice, and time.

Inside Plant (ISP) Considerations:

- Fire Safety Ratings: Indoor cables absolutely must meet local fire codes, which usually means using plenum or riser-rated jackets.

- Cable Management: Keeping cables neatly routed in trays and racks isn't just for looks—it prevents damage and makes future work much easier.

- Airflow and Cooling: In data centers, you have to be careful that cable pathways don't block the flow of cool air to servers and switches.

By meticulously following these best practices, we ensure that the finished network gets every ounce of performance that Corning fiber was designed to deliver.

Achieving Network Excellence with a Turnkey Partner

Knowing the technical details of Corning fiber is one thing, but actually turning that potential into a real-world, high-performance network is a completely different ballgame. A spool of the world's best fiber is, at the end of the day, just a raw material. Its true value is only unlocked through meticulous planning, expert hands-on execution, and uncompromising quality control out in the field.

This is where a turnkey partner like Southern Tier Resources steps in.

An end-to-end partner closes the gap between a network blueprint on paper and a fully operational, revenue-generating asset. We handle every single phase of the project lifecycle, making sure the exceptional quality of Corning materials is protected and even enhanced at every stage. This single-source responsibility gets rid of the communication silos and blame games that so often derail projects with multiple vendors, preventing costly delays and nagging performance issues down the road.

From Design to Deployment

The real work starts long before the first cable is ever pulled. Solid network design and route planning are the foundation of any successful build. Our engineers meticulously map out the most efficient and resilient pathways, factoring in every environmental variable and potential obstacle to make sure the network is built to last.

This initial phase demands absolute precision. For large-scale fiber optic projects, particularly those tied into new construction or major renovations, a turnkey partner often relies on sophisticated tools like to accurately forecast and manage materials, labor, and costs, keeping the entire project running smoothly.

Once the plan is locked in, our skilled crews get to work. They are true masters of their craft, trained in the latest installation techniques that safeguard the integrity of the Corning fiber. This isn't just about pulling cable; it's a science.

- Expert Splicing: Our technicians use state-of-the-art fusion splicers to create connections with the lowest possible signal loss, effectively making two separate fibers perform as one perfect, continuous strand.

- Rigorous Testing: We deploy OTDRs and other advanced diagnostic tools to verify every single connection not only meets but exceeds industry performance standards. No connection gets a pass until it’s perfect.

- Detailed As-Builts: After the work is done, we create precise, detailed documentation that maps the entire network. These "as-built" records are invaluable for future maintenance, troubleshooting, and upgrades.

The Value of Deep Experience

There’s no substitute for experience. It’s what helps you avoid the common, costly mistakes that can cripple a network from day one. Our teams understand the subtle but critical differences in handling various Corning fiber types—from respecting the tight bend radius of ClearCurve in a crowded data center to managing the precise tension on an aerial OSP run. This practical expertise ensures we get every last bit of performance out of the fiber.

A turnkey partner's value isn't just in what they build, but in the problems they prevent. By controlling the process from start to finish, we eliminate the finger-pointing and ensure every component works together perfectly.

Ultimately, achieving genuine network excellence is about more than just buying the best materials. It requires a partnership built on trust, deep expertise, and a shared commitment to quality. Southern Tier Resources provides this all-in-one approach, giving you a single point of accountability for designing, building, and maintaining the fiber infrastructure your business depends on. And our commitment doesn't end when the project is done; we provide ongoing support to keep your network operating at peak performance for its entire lifecycle.

Your Questions About Corning Fiber, Answered

When you're planning a network build, the details matter. It's only natural to have questions, especially when it comes to the very foundation of your infrastructure. Let's tackle some of the most common questions we hear about Corning fiber to give you the clarity you need.

What Makes Corning Fiber Different From Other Brands?

It really comes down to three things: a legacy of invention, incredibly precise manufacturing, and a massive commitment to research and development. Corning didn't just join the fiber optics industry; they basically created it by inventing the first low-loss optical fiber back in 1970.

That spirit of innovation continues today with game-changing products like their bend-insensitive ClearCurve fiber. For anyone building a network, this history of excellence means you're getting unmatched performance, field-proven reliability, and a product built to last. It’s why experts like us at Southern Tier Resources trust Corning fiber for our most critical infrastructure projects—we know it will perform predictably and dependably every single time.

Corning is still pushing the envelope, working with partners like Microsoft on what's next. Their new Hollow Core Fiber is designed to deliver data up to 47% faster with 33% lower latency than standard fiber, setting a new bar for cloud computing and AI.

Can I Mix Corning Fiber With Fiber From Other Manufacturers?

Technically, you can splice fibers from different brands as long as they meet the same ITU-T standard (like G.652.D). However, we strongly advise against it.

Even tiny differences in the glass chemistry or the physical geometry between manufacturers can lead to higher signal loss right at the splice point. Worse, these mismatches can create subtle, long-term reliability problems that are a nightmare to track down later. To ensure consistent, end-to-end performance and simplify maintenance down the road, the best practice is always to stick with a single, high-quality manufacturer like Corning for any given network run.

Is Single-Mode Fiber Always Better Than Multimode Fiber?

Not at all. The right choice is completely dependent on the job at hand. Single-mode is the clear winner for long-haul routes and networks demanding the absolute highest bandwidth. It's the go-to for telecom backbones connecting cities or linking data centers miles apart.

On the other hand, for shorter distances—like inside a single building or across a campus (usually under 500 meters)—multimode fiber is often the smarter, more economical choice. The transceivers that light up multimode fiber are significantly less expensive than their single-mode counterparts. This makes it a much more cost-effective solution for high-density, short-reach applications where you simply don't need the marathon-running capabilities of single-mode.

Ready to build a reliable, high-performance network with the industry's leading fiber optic solutions? Contact Southern Tier Resources today to see how our turnkey approach ensures your project is delivered on time, within budget, and to the highest quality standards.