Corning fiber optic cable is, quite simply, the physical medium that powers our digital world. It's the specialized glass highway that carries data as pulses of light, giving us the incredible speed and rock-solid reliability needed for everything from 5G networks to global cloud infrastructure.

When you think about it, nearly every video call, cloud app, or data transfer relies on this invisible network. In this system, Corning fiber cable is the foundational pavement—the high-performance, ultra-dependable pathway that makes modern communication possible.

Choosing the right cable isn't just a technical detail; it's a critical strategic decision. The choice directly impacts network speed, long-term performance, and whether your infrastructure can handle the data demands of tomorrow. That’s why we, as infrastructure partners, are so meticulous when selecting specific Corning products for projects, whether it's for a global telecom carrier or a massive data center.

The Bedrock of Global Connectivity

Corning’s impact on modern network infrastructure is hard to overstate. As the undisputed world leader in optical fiber, the company shipped its one billionth kilometer of fiber back in September 2017—a staggering figure that speaks volumes about its market dominance.

This leadership didn't happen by accident. It's built on a legacy of relentless innovation and an obsession with quality. For anyone building or operating a network, this translates into real-world advantages:

- Exceptional Performance: You get consistently low signal loss (attenuation) and massive bandwidth capacity. Data simply travels farther and faster.

- Unmatched Reliability: Decades of materials science expertise go into creating cables that can withstand harsh deployment conditions, from underground conduits to aerial installations.

- Future-Ready Scalability: Corning offers an incredibly diverse portfolio, allowing for tailored solutions that fit the specific needs of any project, be it a dense urban fiber rollout or a rural broadband initiative.

The real value in using a premium Corning fiber cable is peace of mind. You're building a network on a foundation that can support escalating bandwidth demands for years, avoiding the high cost and disruption of a premature rip-and-replace.

Ultimately, getting a handle on this foundational technology is essential for anyone involved in network design, construction, or maintenance. Just as important is securing the data that runs over this infrastructure, a topic we explore in our guide on protecting network data. This guide will serve as your roadmap, helping you navigate the complexities of fiber selection and deployment with confidence.

A Field Guide to Corning's Key Cable Product Families

Corning's massive fiber optic cable portfolio isn't just a list of products; it's a toolbox engineered to solve specific, real-world problems. The trick isn't memorizing part numbers but understanding which tool to grab for which job—whether you're connecting continents or wiring up a single data hall.

Think of it like choosing the right tires for your truck. You need all-terrain tires for muddy backroads and highway treads for long hauls. In the same way, picking the right Corning fiber cable means matching its design and construction to the unique demands of the project.

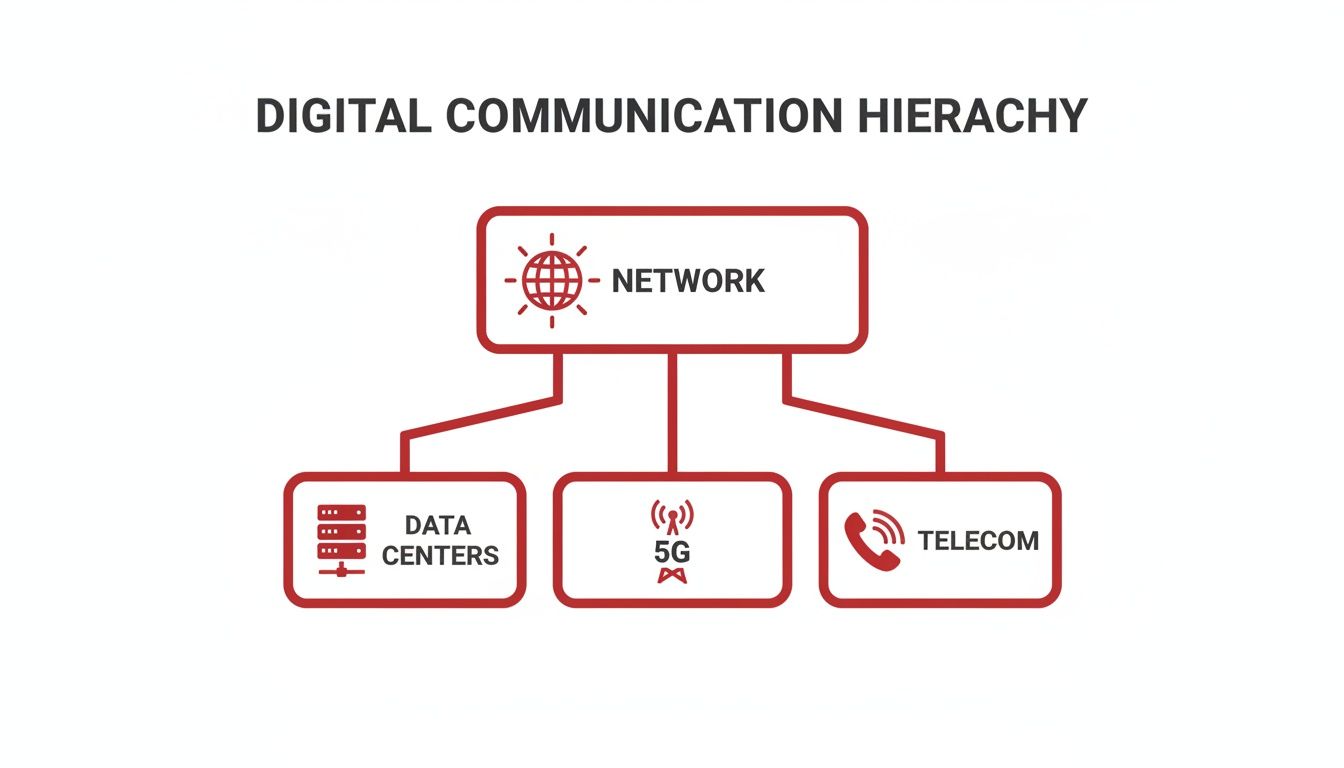

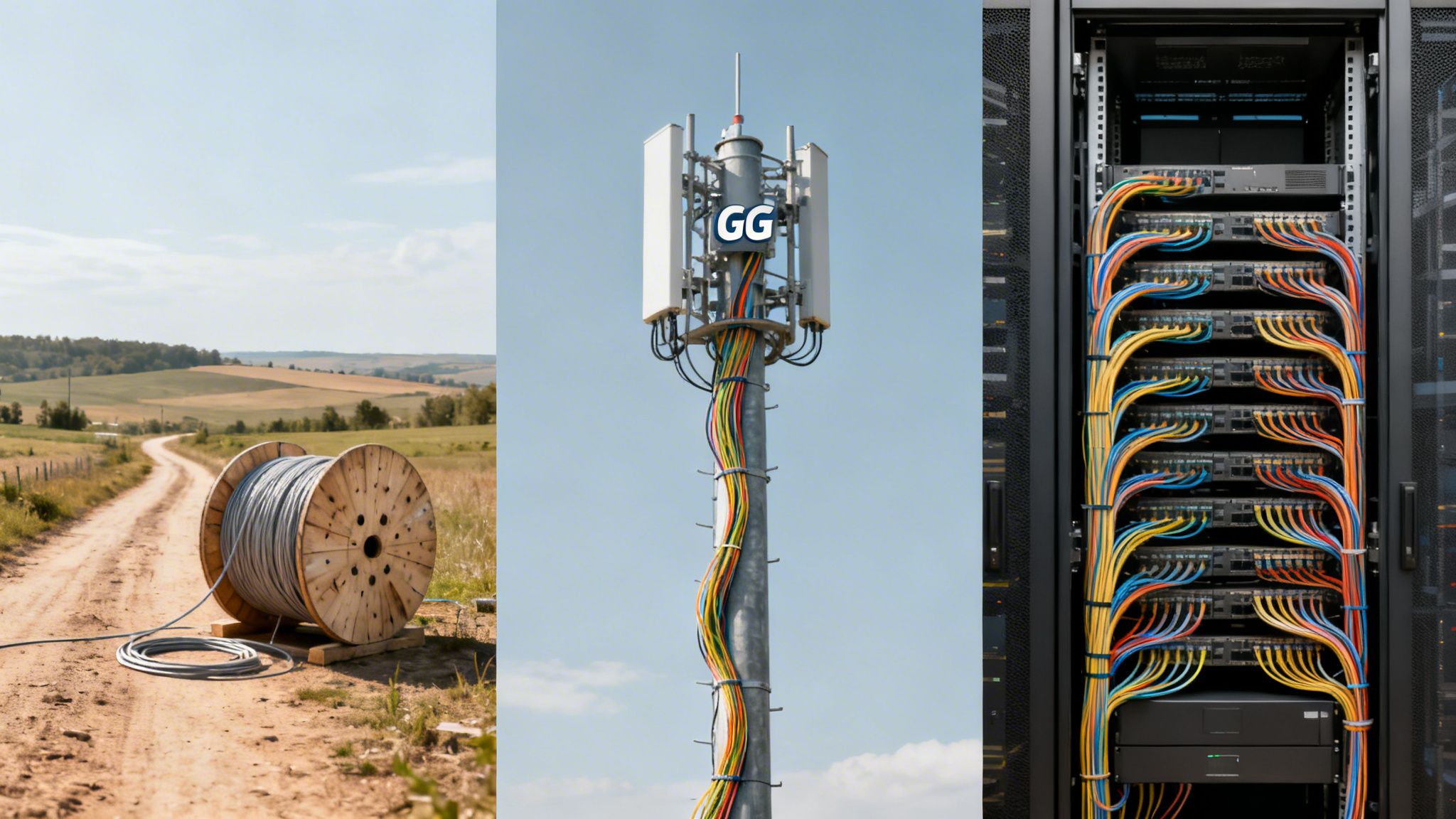

This diagram shows how these specialized cables really form the physical backbone of our entire digital world, connecting everything from global networks down to the local 5G towers and data centers that power our daily lives.

It’s a great visual reminder that high-performance fiber is the universal foundation, but the specific type of fiber needed changes drastically depending on where you are in the network.

To make this easier, here's a quick breakdown of how these major product lines fit into different environments.

| Product Family | Primary Environment | Key Benefit | Typical Use Case |

|---|---|---|---|

| ALTOS® | Outside Plant (OSP) | Extreme durability and weather resistance | Long-haul telecom, ISP backbones, FTTH networks |

| RocketRibbon® | High-Density Data Centers | Maximum fiber count in minimal space | Hyperscale data halls, colocation interconnects |

| FREEDM® | Indoor/Outdoor & Campus | Versatility and fire-safety compliance | Building-to-building connectivity, enterprise backbones |

| MiniXtend® | Microducts & Congested Pathways | Compact design for tight spaces | Crowded conduits, data center upgrades, FTTH drops |

This table gives you the at-a-glance view, but let's dig into what makes each one tick.

ALTOS: The Workhorse for Outdoor Deployments

When you need a cable that can survive decades of abuse from the elements, you turn to ALTOS®. This is the go-to family for almost all outside plant (OSP) work—think long-haul telecom routes, city-wide metro rings, and the fiber backbones that feed neighborhoods in an FTTH buildout.

Their legendary toughness comes from a loose-tube design. The delicate glass fibers sit safely inside protective tubes, buffered from moisture, extreme temperature swings, and the physical stress of being buried in the ground or lashed to a pole. For a contractor like Southern Tier Resources, ALTOS is the default choice for building the main arteries of a rural broadband network because we know it will just work, year after year, no matter the weather.

RocketRibbon: Built for Extreme Density

Now, let's step inside. The RocketRibbon® family was born out of the relentless pressure for density inside modern data centers. In these facilities, every square inch of pathway space is precious real estate, and network engineers have to cram an incredible amount of connectivity into very tight spaces.

RocketRibbon’s genius is in its design. It bundles up to 12 fibers into a flat ribbon that can be rolled, allowing for massive fiber counts in a surprisingly small cable. This construction doesn't just save space; it dramatically speeds up installation.

The real game-changer is mass-fusion splicing. Instead of painstakingly splicing one fiber at a time, RocketRibbon lets technicians fuse an entire 12-fiber ribbon at once. This single innovation can cut installation time and labor costs by as much as 70%—a massive advantage in a hyperscale data center build where time is money.

FREEDM & MiniXtend: The Versatility Experts

For everything in between, the FREEDM® and MiniXtend® families offer incredible flexibility and, crucially, safety. These cables are designed with specific fire-safety ratings (like plenum and riser) that are mandatory for running cable through a building's air-handling spaces or vertically between floors.

- FREEDM® Cables: These are the perfect hybrid solution. Many are rated for both indoor and outdoor use, making them ideal for campus environments. You can run one continuous cable from a manhole, across a parking lot, and straight into a communications closet without a single splice.

- MiniXtend® Cables: As the name suggests, these are all about a minimal footprint. Designed for installation in microducts, their small diameter and high fiber count are perfect for threading new capacity through congested enterprise backbones or data center pathways.

Ultimately, navigating these product families is about putting the environment first. An experienced partner will always start by assessing the real-world challenges—be it punishing weather, cramped conduits, or strict fire codes—and only then select the specific Corning fiber cable engineered to conquer them. That’s how you build a network that’s not just fast, but fundamentally reliable and safe.

Choosing the Right Cable Specifications

Once you’ve looked past the brand names and product families, the real performance of a Corning fiber cable comes down to its technical specs. This is where the rubber meets the road. Picking the right glass type, fiber count, and jacket material is what separates a network plan on paper from a network that actually delivers. These details are the cable’s DNA, defining what it can—and can’t—do.

Think of the glass inside the fiber as the lanes on a highway. Some are built for local traffic, while others are designed for high-speed, cross-country journeys. That’s the fundamental difference between the two main types of optical fiber.

Single-Mode vs Multi-Mode Glass

Your first big decision is the type of glass. Each one is engineered for a completely different scale of data transmission. Picking the wrong one is like trying to use a quiet side street to handle rush-hour freeway traffic—it just won’t work.

Single-Mode Fiber (SMF): This is your long-haul champion. It has a tiny core that forces a single, focused ray of light down the path, which dramatically reduces distortion over incredible distances. Corning’s SMF-28® Ultra fiber is a perfect example; it’s the workhorse that forms the backbone of global telecom and ISP networks where signals have to travel for dozens, or even hundreds, of kilometers without failing.

Multi-Mode Fiber (MMF): This type has a much larger core that allows multiple rays of light to bounce along inside it at the same time. While this makes it much cheaper, it also limits its effective range to just a few hundred meters. You’ll find Corning's bend-insensitive ClearCurve® multi-mode fiber everywhere in data centers and enterprise building backbones, where connections are short, dense, and need to be cost-effective.

For a network designer, the choice is pretty straightforward: single-mode is for distance, multi-mode is for density. Try to use multi-mode for a long-haul link and you’ll get complete signal failure. Use single-mode for every short little patch inside a data center, and you’ll just be wasting money.

Fiber Count and Cable Density

With the glass type settled, the next question is about capacity. How many individual fibers do you need to pack into the cable? This can range from a handful of strands to massive cables with over 3,000 fibers. Today’s network demands, especially in data centers feeding power-hungry AI workloads, are pushing those counts higher than ever before.

This is where clever innovations like Corning's rollable ribbons really shine. This design makes it possible to pack an astonishing number of fibers into a surprisingly small cable. You can run thousands of connections through existing conduits that everyone thought were already full, which is a game-changer for scaling up infrastructure without digging new trenches.

Matching the Jacket to the Environment

Finally, the cable's outer jacket is its suit of armor. It has nothing to do with transmitting data, but it's absolutely critical for protecting the delicate glass fibers inside from moisture, crushing forces, and fire. You have to match the jacket material to the deployment environment, or you're asking for trouble down the line.

- Plenum/Riser: These are fire-retardant jackets required by building codes for indoor installations. Plenum-rated jackets are for air-handling spaces (like ceilings), and riser-rated jackets are for vertical runs between floors.

- Outdoor (PE): Polyethylene jackets are tough, UV-stable, and water-resistant. They're built to survive the harsh conditions of being buried directly in the ground or strung up on poles.

Translating project requirements into these three core specs—glass, count, and jacket—is how you ensure the Corning fiber cable you choose is perfectly suited for the job. Get it right, and you've locked in performance and reliability from day one.

How Corning Fiber Performs in the Real World

Specs on a datasheet are one thing, but what really matters is how a Corning fiber cable holds up in the field. The true test comes when you’re deploying these products to solve tough infrastructure problems—turning a blueprint into a living, breathing network that connects communities and drives business.

Let's walk through three common scenarios where picking the right Corning cable makes all the difference, from lighting up homes with gigabit internet to building the foundation for 5G and cloud computing.

Powering Fiber-to-the-Home Networks

When building a Fiber-to-the-Home (FTTH) network, the mission is clear: create a rock-solid, high-speed backbone that will serve a community for decades. This is precisely where the legendary durability of Corning's ALTOS® loose tube cables comes into play. These cables are the workhorses of the network, forming the main distribution lines buried underground or strung along poles.

Out there, they have to survive everything from freezing winters to scorching summers. An experienced contractor like Southern Tier Resources chooses ALTOS® for these main arteries because its tough construction shields the delicate glass from moisture and temperature swings. It’s what guarantees the network stays up and running, delivering consistent service to thousands of people no matter what the weather is doing.

Enabling Hyperscale Data Center Connectivity

Step inside a hyperscale data center, and the game changes entirely. The challenges here are all about density and speed. Thousands of servers need to be connected with enormous bandwidth, all crammed into tight, limited pathways. This is the perfect job for a high-density solution like Corning’s RocketRibbon® cables.

These cables are an engineering marvel, packing a huge number of fibers into a compact, rollable ribbon design. For a data center manager, that means more connections in less space, keeping cable trays from becoming a tangled mess. When combined with pre-terminated connectors, RocketRibbon® turns deployment into a near plug-and-play process. This lets hyperscalers bring new server racks online in a fraction of the usual time—a massive advantage when speed is everything.

The ability to quickly deploy high-count fiber is what allows modern data centers to keep pace with the voracious data demands of AI and cloud services. It’s a direct link between physical infrastructure and digital innovation.

Building the Backbone for 5G Rollouts

The push for 5G brings its own unique set of headaches. Every single 5G cell site, whether it's on a massive tower or a small-cell unit on a streetlight, needs a high-capacity fiber link back to the main network. This "fronthaul" connection is absolutely essential for delivering the ultra-low latency and blazing speeds 5G promises.

This demand is fueling major growth in the fiber optic cable market, as explained in this detailed industry report. For these critical links, high-count and environmentally sealed Corning fiber cables are the go-to solution. They provide the sheer data-hauling muscle needed to handle traffic from thousands of mobile devices simultaneously, giving the wireless network a reliable, high-performance foundation.

In every case, choosing the right Corning fiber cable is more than just a technical decision. It's the move that ensures the network you build today is ready for whatever comes next.

Getting It Right in the Field: Installation and Testing

Buying the best Corning fiber cable is a great start, but it’s only half the battle. The real magic happens in the field. To get the performance you paid for, you need flawless installation and meticulous testing. The most advanced fiber in the world won't do you any good if it's kinked, poorly spliced, or improperly handled.

A cardinal rule every seasoned technician lives by is respecting the cable's minimum bend radius. It’s just like a garden hose—if you bend it too sharply, you cut off the flow. In fiber optics, that sharp bend chokes the light signal. While Corning's ClearCurve® glass is incredibly resilient, even it has its limits. A trained crew knows never to push past those limits when pulling, routing, or terminating the cable, as that's how you avoid the kind of signal loss that can bring a network to its knees.

Splicing with Precision, Deploying at Speed

Beyond simply handling the cable correctly, there's the art of splicing. This is where two fibers are fused together, and it demands absolute precision. When done right, a splice creates a connection so seamless that the light signal passes through with virtually zero degradation.

This is an area where Corning has really changed the game. Think about their rollable ribbon technology, which lets crews pack an astonishing 3,456 fibers into a tiny 2-inch duct. They paired this with mass-fusion splicing, a technique that can slash labor hours by an incredible 70%. This isn't just a minor improvement; it's a direct solution to technician shortages and helps accelerate deployments in crowded city environments.

Proving Performance: The Power of Testing

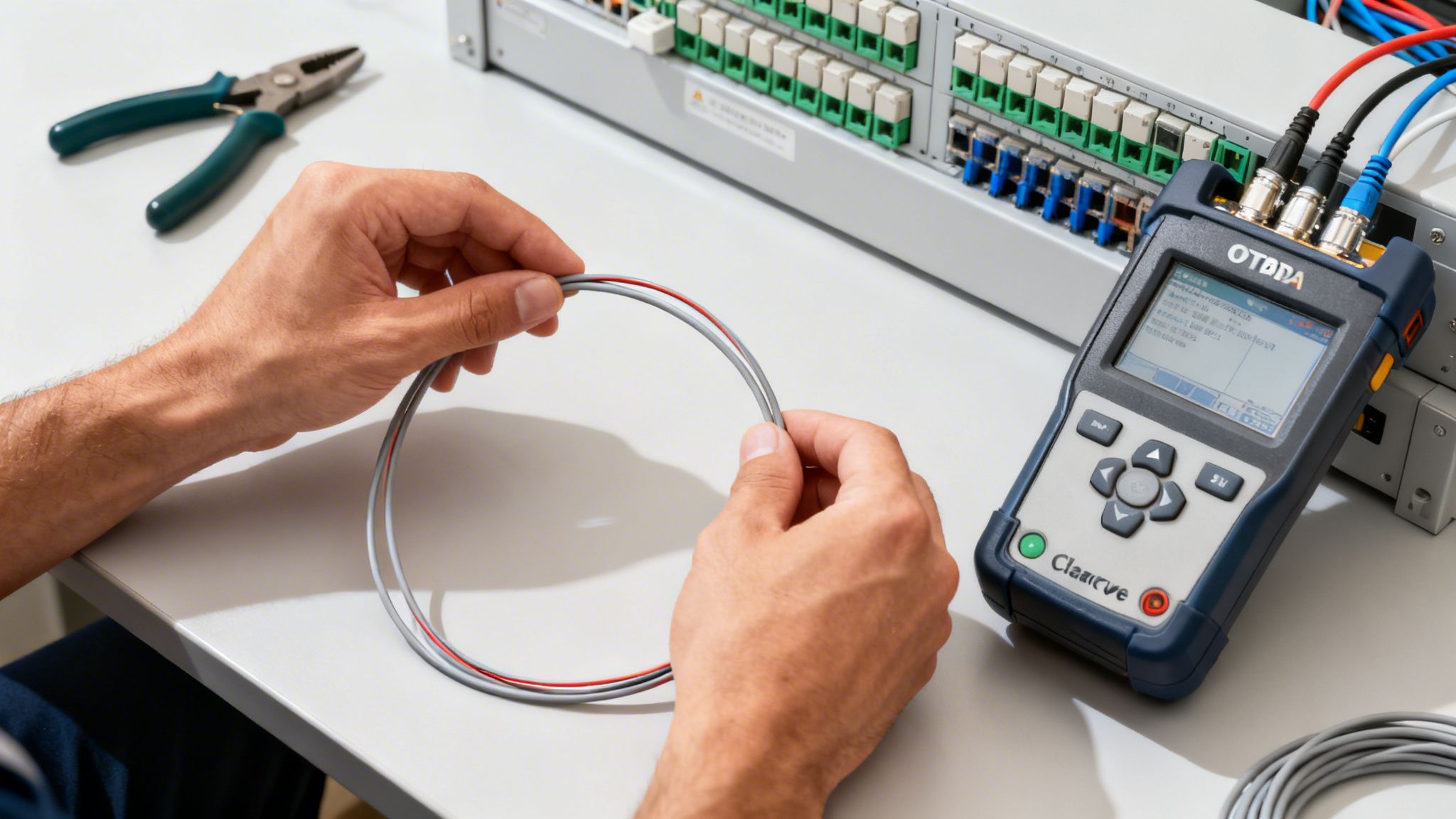

Once everything is physically in place, it’s time to prove the network performs as designed. We're not just flipping a switch to see if it "works." We're certifying that every single strand and connection meets the highest performance benchmarks. That's where specialized testing equipment comes in.

An Optical Time Domain Reflectometer (OTDR) is the go-to tool for this job. It sends a quick pulse of light down the fiber and then listens for the reflections that bounce back. This creates a highly detailed "map" of the entire cable run, allowing technicians to see the exact location of every splice, connector, and potential fault with pinpoint accuracy.

This kind of in-depth testing is the ultimate quality control. When working in areas with a lot of existing underground utilities, we rely on best practices like non-destructive digging to avoid damaging anything and ensure a safe, clean path for the new cable. Protecting our crews and existing infrastructure is paramount, and you can learn more about our commitment in our guide to field safety protocols.

At the end of the day, there’s no shortcut. The only way to build a network that truly delivers is by pairing premium Corning materials with expert installation and exhaustive validation.

The Advantage of a Turnkey Infrastructure Partner

Picking the perfect **Corning fiber cable** is a critical first step, but it’s just that—a first step. Even the most advanced fiber in the world won’t deliver on its promise unless it’s installed with skill and precision. This is where a true turnkey infrastructure partner makes all the difference.A turnkey firm is your single source of truth for the entire project, from the initial sketch to the final light-up. This unified approach closes the gap between the product spec sheet and the often-messy reality of building physical infrastructure in the real world.

From Design to Deployment

An experienced partner will guide your project through every phase, ensuring nothing gets lost in translation between different teams. This prevents the kind of expensive miscommunications and frustrating delays that can derail projects relying on a patchwork of disconnected vendors.

The process covers the full lifecycle:

- Initial Network Design: We start by translating your business needs into a rock-solid engineering plan.

- Cable Procurement: Next, we source the exact Corning fiber products required for the design, no more and no less.

- Expert Installation and Splicing: Our field technicians then deploy the cable, adhering to the strictest industry standards for a clean, professional build.

- Final Testing and Validation: Finally, we certify every single strand of fiber to guarantee it meets or exceeds performance specs.

The real value of a turnkey partner isn’t just about checking boxes; it's about owning the outcome. When one team is accountable for everything from the blueprint to the final OTDR test, the entire focus shifts to delivering a network that just works, period.

Guaranteeing Your Infrastructure Investment

At the end of the day, your physical network is a long-term asset. The quality of its construction has a direct line to its reliability, how easily it can scale, and what it will cost you to own and operate for years to come.

While a premium Corning fiber cable gives you the best raw material, the right partner is the one who transforms that material into a robust, future-ready network.

This end-to-end responsibility is what protects your investment and ensures it delivers the best possible return. To see how this integrated approach can take the complexity out of your next network build, learn more about the turnkey fiber optic solutions that power modern connectivity.

Frequently Asked Questions

When it comes to fiber optics, the details matter. We get a lot of great questions from clients trying to pinpoint the perfect Corning fiber cable for their network, so we’ve put together answers to a few of the most common ones.

What Is the Best Cable for Long Distances?

For any run that stretches beyond a few hundred meters, single-mode fiber (SMF) is really the only way to go. Its core is designed to carry a single, highly focused beam of light, allowing the signal to travel for miles with incredibly low signal loss.

This is why Corning's SMF-28® series has become the gold standard for telecom backbones, ISP networks, and any long-haul connection. Multi-mode fiber, on the other hand, is built for short-reach jobs, like connecting servers inside a single data center.

How Do I Understand Cable Jacket Ratings?

Cable jacket ratings are all about fire safety and are strictly dictated by local building codes. You can think of them as a cable's official safety certification for where it can be installed inside a building.

- Plenum (CMP): This is the highest rating. It's required for any cable run through air-handling spaces, like the area above a drop ceiling, because it's designed to produce very little smoke if exposed to fire.

- Riser (CMR): This rating is for cables running vertically between floors through non-plenum shafts or walls.

Getting the rating right isn't just a suggestion—it's a critical part of a safe, compliant installation.

Are Pre-Terminated Cables Worth It?

In many situations, absolutely. For data centers and other controlled environments, pre-terminated Corning fiber cable assemblies are a game-changer. They arrive at your site with the connectors already installed and factory-tested.

This approach saves a massive amount of time on-site, eliminates the need for expensive field splicing gear, and ensures top-tier performance from the moment it's plugged in. The initial cost might be a bit higher, but the savings on labor and the peace of mind that comes from avoiding installation errors usually deliver a fantastic return.

Ready to build a reliable, high-performance network with the right materials and expert installation? Contact Southern Tier Resources today to discuss your project requirements. Find out more about our turnkey solutions at https://southerntierresources.com.