In our hyper-connected world, Corning fiber optic cables are the bedrock of modern communication. These strands of glass, each thinner than a human hair, are the unsung heroes carrying the load for everything from global internet traffic to the latest 5G wireless networks. They are the high-speed data highways that make it all possible.

Understanding the Backbone of Modern Networks

If you think of the global data network as a massive central nervous system, then Corning fiber optic cables are the primary nerve pathways. They are responsible for transmitting staggering volumes of information at the speed of light. This technology is what props up the digital services we take for granted every day, creating the essential link between data centers, telecom hubs, and every device in your hand or home.

Without this solid physical layer, the performance of cloud computing, real-time video streaming, and online gaming would simply collapse. For any network engineer or data center operator, the reliability of this foundation isn't just important—it's everything.

A Legacy of Innovation

Corning’s story in this space is one of relentless innovation that has constantly redefined the limits of data transmission. Their impact is so immense that the company has manufactured and shipped over one billion kilometers of optical fiber. It's a staggering figure that makes Corning the most widely deployed brand on the planet, with its fiber running through everything from transoceanic cables to local broadband lines.

This deep-rooted reputation for quality gives network architects the peace of mind they need when designing and building mission-critical infrastructure. Getting the physical components right from the start is crucial, and you can learn more about this by reviewing our guide to https://southerntierresources.com/goodscode/cabling/2545392887.

In an industry where downtime is measured in lost revenue and broken trust, the physical integrity of the network is non-negotiable. High-quality fiber optic cabling isn't just another component; it's an insurance policy against poor performance and signal loss.

Powering Mission-Critical Applications

The demand for faster, more dependable data transmission is only accelerating. Corning’s solutions are specifically engineered to tackle the challenges of today's most demanding applications:

- Hyperscale Data Centers: These facilities need high-density, low-latency connectivity to link thousands of servers for AI and cloud computing, and Corning fiber delivers.

- 5G Wireless Deployments: The high bandwidth and low latency of 5G depend entirely on robust fronthaul and backhaul fiber connections.

- Rural Broadband Initiatives: Extending high-speed internet to underserved areas requires durable and reliable long-haul fiber that can withstand the elements.

To really grasp why fiber is so indispensable, it helps to understand the core advantages of wired networks, which almost always rely on fiber for peak performance. At the end of the day, every single bit of data has to travel over a physical medium, and the quality of that medium sets the ceiling for what the entire network can achieve.

A Look at Corning's Core Fiber Optic Solutions

When you're dealing with Corning fiber optic cables, the first thing to grasp is the fundamental split between its two main technologies: single-mode and multimode. They're built for entirely different jobs, and picking the right one is the crucial first step in any solid network design.

Think of it like a highway. Single-mode fiber (SMF) is a perfectly straight, one-lane tunnel built for a Formula 1 car. Light zips down its tiny 9-micron core in a single, direct path, or "mode." This focused beam suffers from very little distortion, which means it can travel incredible distances with minimal signal drop. That's why SMF is the undisputed king for long-haul, metro, and carrier networks.

Multimode fiber (MMF), on the other hand, is more like a bustling multi-lane city street. Its much wider core (50 or 62.5 microns) lets light travel in many different paths at once. This works well for shorter trips, like inside a data center or across a campus, but over longer distances, those different light paths start to blur the signal. This effect, called modal dispersion, is what limits MMF's reach.

To help you get a clearer picture of where each Corning product fits, here’s a quick overview of their main fiber families.

Corning Fiber Optic Cable Families at a Glance

This table breaks down the main players in Corning's lineup, highlighting their key features and where they truly shine in real-world deployments.

| Fiber Family | Fiber Type | Core/Cladding Diameter | Key Feature | Primary Application |

|---|---|---|---|---|

| SMF-28® | Single-Mode | 9.2/125 µm | Industry-standard reliability, low attenuation | Long-Haul, Metro, Carrier Networks |

| ClearCurve® | Single-Mode | 9.2/125 µm | Extreme bend-insensitivity | Data Centers, FTTx, High-Density |

| RocketRibbon® | Single-Mode (Ribbon) | 9.2/125 µm | Ultra-high density, fast splicing | Hyperscale Data Centers, Backbone |

| Vascade® | Single-Mode | Varies | Optimized for submarine transmission | Undersea Cable Systems |

| ClearCurve® OM | Multimode (OM2/3/4) | 50/125 µm | Bend-insensitive multimode performance | Enterprise LAN, Data Center Interconnects |

Each of these fiber types was engineered to solve a specific set of challenges, from crossing oceans to navigating the tight confines of a server rack.

SMF-28 Fiber: The Workhorse of Global Networks

For most network engineers, Corning’s SMF-28® family is synonymous with reliable, industry-standard single-mode fiber. It’s the very foundation of a massive portion of the world's telecom infrastructure—the bedrock for long-distance data transmission.

Its design is all about performance and backward compatibility. This ensures that when you build out a new network segment, it integrates perfectly with decades of existing infrastructure. That makes it a smart, cost-effective choice for carriers and ISPs rolling out metro and long-haul routes where consistency is non-negotiable.

ClearCurve Fiber: Conquering the Tight Squeeze

Standard single-mode fiber is fantastic for long, straight runs, but its performance plummets if you bend it too sharply. This is a huge problem in the packed environments of data centers or Fiber-to-the-Home (FTTx) installations, where tight corners are just a fact of life. That’s precisely where Corning’s ClearCurve® bend-insensitive fiber comes in.

ClearCurve® is engineered with a special optical "trench" around the core. This trench acts as a guardrail, reflecting stray light back into the core instead of letting it leak out when the cable is bent. This brilliant design allows the fiber to handle tight turns with almost no signal loss—a task that would cripple standard fiber.

The practical benefits here are huge:

- Fewer Installation Headaches: Technicians can route cables in crowded server racks and wall boxes without constantly worrying about creating performance-killing microbends.

- More Compact Hardware: The ability to handle a smaller bend radius lets you use smaller, higher-density enclosures, which saves priceless rack space.

- Built for the Future: It guarantees network reliability even as you cram more connections into already tight pathways.

RocketRibbon Cables: Maximum Density, Minimum Space

As the demand for fiber explodes in hyperscale data centers and carrier hubs, the physical space in ducts and conduits has become incredibly valuable real estate. Corning’s RocketRibbon® cables tackle this problem head-on by packing a staggering number of fibers into an impressively small and lightweight cable.

The secret sauce is their ribbon-on-demand technology. The cables contain densely packed ribbons of 12 or 24 fibers bonded together. The clever part? Technicians can easily separate these ribbons into smaller groups or even individual fibers by hand—no special tools needed. If you want to dive deeper into the nitty-gritty, this breakdown of Corning fiber specifications is a great resource.

This design gives you the best of both worlds: the lightning-fast splicing speed of mass fusion ribbon splicing combined with the easy routing of individual fibers. For network builders, this translates to faster deployments, less duct congestion, and more capacity in your existing infrastructure, all of which drive down project costs.

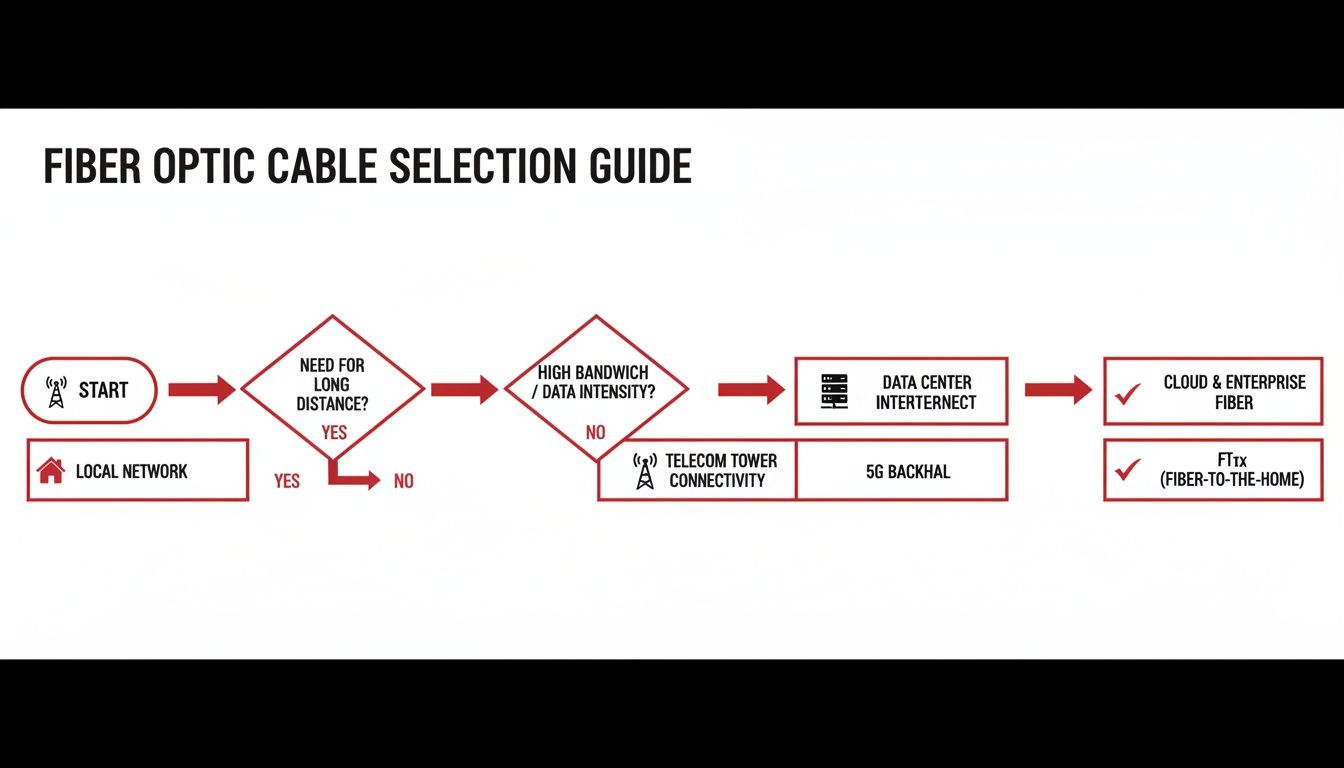

How to Choose the Right Fiber for Your Network

Picking the right Corning fiber optic cable is more than a technical task—it’s a strategic move that defines your network's performance, budget, and future. You need a practical way to move from product specs to real-world application, matching the right fiber to the right job. Getting this right prevents costly bottlenecks and ensures the infrastructure you're building today will stand the test of time.

An informed choice comes down to understanding the specific challenges of your environment. Are you building a sprawling metro network, a high-density data center, or a rugged 5G cell site? Each scenario forces different trade-offs between distance, bandwidth, density, and cost.

This decision has never been more important. The global demand for fiber optic cable is surging, fueled by massive 5G rollouts and data center expansions. Market forecasts show the industry climbing from USD 13 billion to a staggering USD 34.5 billion by 2034. This highlights the incredible scale of investment happening right now. You can discover more insights about the explosive growth of the fiber optic cable market and what's driving it.

Selecting Fiber for Telecom Carriers

For telecom carriers building out metro and long-haul networks, single-mode fiber is still the king. But it’s not as simple as just picking one type. The real decision is about balancing the upfront cost of a premium fiber against the operational savings it can deliver over the long run.

Metro Routes (Under 80 km): For most city-wide rings, Corning's SMF-28® ULL fiber is the go-to choice. Its exceptionally low attenuation—meaning less signal loss—allows carriers to push signals further. This can mean reducing or even eliminating expensive optical amplifiers, which cuts down on both initial capital and ongoing operational costs.

Long-Haul Routes (Over 80 km): When you get into true long-haul networks that cross states or countries, the advantages of advanced fibers become even clearer. A fiber with superior optical properties might cost more per meter, but it can dramatically simplify the entire network system, leading to massive savings over the life of the network.

Optimizing Data Center Connectivity

Inside the data center, the game changes completely. Forget about extreme distances; the challenge here is extreme density. The goal is to cram as much bandwidth as possible into very tight spaces, all while keeping things cool. This is where bend-insensitive fibers, both multimode and single-mode, really shine.

The choice between different multimode fibers (MMF) usually comes down to the data rate and distance you need:

- ClearCurve® OM3: This is a solid, cost-effective choice for 10 Gbps links running up to 300 meters, perfect for standard server-to-switch connections.

- ClearCurve® OM4: Supporting 40 Gbps and 100 Gbps up to 150 meters, OM4 has become the workhorse for most modern data center interconnects.

- ClearCurve® OM5: This fiber was built for short-wavelength division multiplexing (SWDM), which lets you send multiple light signals over a single fiber pair. It paves a clear path to 400 Gbps and beyond over the same distances as OM4.

For network architects, this is a future-proofing calculation. OM4 might handle today's traffic just fine, but deploying OM5 provides a built-in upgrade path, helping you avoid a painful and expensive "rip and replace" project a few years down the road.

Fortifying 5G Deployments

5G networks are incredibly demanding on the fiber that supports them. The fronthaul and backhaul connections linking cell sites to the core network need more than just high bandwidth—they require serious durability to survive harsh outdoor conditions.

This is where Corning’s ClearCurve® bend-insensitive single-mode fiber becomes essential. Technicians are constantly working in cramped cabinets and tight conduits, where cables get bent, pulled, and shoved. A standard fiber would lose signal integrity under that kind of stress, leading to dropped calls and sluggish data.

The tough, bend-friendly nature of ClearCurve ensures the signal stays strong, delivering the low-latency, high-throughput connection that 5G promises. This reliability is key to keeping the network running smoothly and cutting down on expensive truck rolls for repairs.

Mastering Fiber Deployment and Maintenance

Picking the right Corning fiber optic cable is just the start. The real test is in the field, where flawless execution makes the difference between a high-performance network and an underperforming asset. A successful deployment isn’t magic—it’s the outcome of disciplined, methodical work from the moment a cable reel hits the site to the long-term maintenance that keeps the network humming for years.

Even tiny mistakes during installation can introduce signal loss, crippling network speed and reliability. Think of it like building a high-performance engine: you can have the best components money can buy, but if they aren't assembled with absolute precision, you’ll never see what that engine can really do. The exact same principle applies to your fiber network.

Pre-Deployment Best Practices

Your success starts long before the first fiber is ever pulled. Proper handling and storage are non-negotiable for preventing damage that might be invisible to the naked eye but will absolutely show up on your test gear. Cables need a clean, dry place to live, far from extreme temperatures and direct sunlight that can break down the outer jacket over time.

Most importantly, treat the cable reel with respect. Never, ever drop it from a truck or roll it across rough, uneven ground. That kind of impact can cause microfractures inside the glass fiber, creating attenuation points that will haunt your network for its entire life.

Critical Installation Techniques

Once you're ready to deploy, it's all about precision. Every single action your installation crew takes directly affects the network's final performance numbers. The two biggest culprits for permanent fiber damage are improper bend radius and excessive pulling tension.

- Respecting Bend Radius: Every cable has a minimum bend radius specification. If you bend it any tighter, light starts to leak from the core, which means significant signal loss. This is exactly why bend-insensitive fibers like Corning's ClearCurve® are so valuable, especially in tight quarters.

- Managing Pulling Tension: Yanking on a cable with too much force can stretch the fiber, permanently changing its optical properties or even causing it to fracture. Always use a tension meter and stay well below the manufacturer's maximum pulling tension.

This flowchart gives you a great visual guide for matching the right Corning fiber to the job.

You can see how different needs—from long-haul telecom routes to jam-packed data centers—point you toward the ideal fiber solution.

Post-Installation Validation and Testing

Once the physical work is done, it's time to prove the quality of the installation. Rigorous testing isn't just a final check; it creates the essential baseline data you'll need for any future troubleshooting. If you skip this step, you're flying blind when problems eventually pop up.

For any professional fiber deployment, two tests are absolutely mandatory:

- Optical Loss Test Set (OLTS): This test measures the total amount of light lost from one end of a link to the other, known as insertion loss. It gives you a clear pass/fail result based on the loss budget you designed for the network.

- Optical Time Domain Reflectometer (OTDR): Think of an OTDR as radar for your fiber cable. It sends a light pulse down the line and measures the reflections, creating a detailed map of the entire link. This trace shows you the location and performance of every splice, connector, and fault.

A clean OTDR trace is the ultimate proof of a high-quality installation. It doesn't just validate the overall link performance; it confirms the craftsmanship of every single splice and connection, giving that fiber strand a permanent birth certificate.

Proactive Maintenance Strategies

A fiber network is a long-term investment, and proactive maintenance is what guarantees its reliability for decades. This is about preventing outages, not just reacting to them. A solid maintenance plan includes routine physical inspections of enclosures and pathways to check for damage from weather, pests, or nearby construction. It’s also vital to keep splice points protected and accessible by using components like a properly sized handhole.

On top of that, your most powerful maintenance tool is diligent documentation. Keeping accurate, up-to-date records of fiber routes, splice locations, and the initial test results can slash troubleshooting time. When an issue occurs, your technicians can pull up the as-built documentation and OTDR traces to pinpoint the problem area in minutes, not hours, minimizing downtime and saving money.

Sourcing and Compatibility Best Practices

Getting your fiber network deployed successfully goes way beyond just picking the right cable and installing it correctly. You need a solid, disciplined approach to sourcing your materials and ensuring every single component plays nicely together. The choices you make here have a direct line to your network's performance, security, and ultimately, your total cost of ownership.

Let's start with the most critical rule of thumb: always, always source your Corning fiber optic cables from an authorized distributor. The market is flooded with counterfeits and "gray market" products that look convincing but will absolutely fail you when it counts. These knockoffs are often made with cheap glass and subpar coatings, which leads to terrible signal loss, frequent breaks, and a much shorter lifespan.

Going with unauthorized materials doesn't just void your warranty; it opens the door to massive security risks and performance headaches that can bring a mission-critical network to its knees.

Ensuring End-to-End Compatibility

Think of your network as a high-performance ecosystem. Every single part has to be perfectly matched, because one incompatible component can create a bottleneck that drags the whole system down. It’s like building a race car engine—you wouldn't mix and match premium parts with generic ones and still expect to win.

To get everything working in harmony, you have to nail three key areas of compatibility:

- Fiber-to-Fiber Splicing: When you're extending or repairing a line, you have to match the fiber types exactly. You can splice a standard G.652.D single-mode fiber to a G.657 bend-insensitive one, but it takes specialized fusion splicer settings to handle the different mode field diameters. Get it wrong, and you'll create reflection points and signal loss that are notoriously difficult to track down later.

- Connectors and Hardware: It might sound obvious, but your physical connectors have to match your hardware ports. The most common types you'll see are LC (Lucent Connector) and SC (Subscriber Connector). LCs are smaller and great for high-density data centers, while the bigger SC connectors are known for being tough and durable. Ordering patch panels with the wrong connectors is a surefire way to grind a project to a halt.

- Transceivers and Active Equipment: Your active gear, like your transceivers (SFPs, QSFPs), has to be designed for the specific fiber you’re using. A multimode transceiver simply won't work on a single-mode fiber, and vice versa. Always double-check that the transceiver's wavelength and supported distance fit your fiber type and link budget.

Decoding Corning Technical Datasheets

Your best friend for guaranteeing compatibility is the manufacturer's technical datasheet. This document is the bible, giving you every critical spec you need to make the right call before you buy.

Don't just glance at datasheets. They're the engineering blueprints for your network. A few minutes spent verifying part numbers and specs upfront can save you days of expensive rework and project delays down the road.

When you're looking over a datasheet for Corning fiber optic cables, zoom in on these details:

- Fiber Type: Confirm the exact fiber standard (e.g., G.657.A1, OM4) to make sure it's what your application demands.

- Attenuation: Check the attenuation rating (in dB/km) at the right wavelengths. This has to line up with your link loss budget.

- Cable Construction: Make sure the jacket material (e.g., plenum, riser) meets local fire codes and the construction type (e.g., loose tube, ribbon) is right for the environment you're installing in.

Beyond just picking the right parts, building strong relationships with your suppliers is key to long-term success. Check out these IT vendor management best practices to help keep your procurement and support channels running smoothly. When you pair smart sourcing with obsessive compatibility checks, you're building a network foundation that’s reliable, secure, and ready to perform.

Building a Future-Proof Fiber Infrastructure

At the end of the day, building a high-performance network is about more than just buying the best parts. It’s about turning premium materials into a resilient, long-term asset. All the principles we've covered—from picking the right Corning fiber optic cables to getting the deployment just right—aren't just best practices. They're the absolute foundation for an infrastructure that can handle today’s massive data loads and whatever comes next.

You really see a network's strength not when things are easy, but when it's under pressure. That’s where smart planning and expert execution make all the difference. Top-tier fiber is the right start, but you only realize its true potential through precise installation, demanding tests, and a solid maintenance plan.

From Components to a Cohesive Network

Getting from a pallet of cable reels to a live, future-ready network is a complicated journey. It demands a real grasp of how every single choice—from the first blueprint and splicing method to the final OTDR sweep—shapes the final product. This is precisely where a skilled infrastructure partner proves their worth.

True network resilience is born when superior materials meet deep operational expertise. It's the blend of engineering precision and hands-on experience that ensures your network is built not just for today, but for the innovations of the next decade.

Specialized knowledge is what turns a pile of high-quality components into a successful network. An experienced partner brings essential skills you can't overlook:

- Strategic Design: They map out efficient, scalable network layouts that keep potential failure points to an absolute minimum.

- Precision Execution: They handle the fiber with the care it needs, protecting its optical integrity from the get-go.

- Thorough Validation: They use advanced testing to certify performance and establish a clear baseline for future upkeep.

- Holistic Project Management: They manage every last detail, making sure the project hits its deadline and meets the highest quality standards.

Partnering for Long-Term Success

Ultimately, the real goal is to build an infrastructure that delivers rock-solid performance and a strong return on your investment. The physical layer you put in the ground today is the bedrock for the services you’ll be offering for years—from 5G and IoT to the next wave of AI applications.

Choosing the right Corning fiber optic cables is a critical first step. But teaming up with an expert who can bring that vision to life is what guarantees your network is truly built to last.

Frequently Asked Questions

Got questions? We've got answers. Here are some of the most common things network pros ask us about choosing and installing Corning fiber optic cables. We'll get straight to the practical, real-world answers you need.

What Is the Main Difference Between SMF-28 and ClearCurve Fibers?

The biggest difference comes down to bend performance. You can think of the classic SMF-28® fiber as the workhorse for long, straight shots. It's the go-to for protected pathways in metro and long-haul networks where the cable isn't going to be bent tightly. It’s an incredibly reliable G.652.D standard fiber, but it can suffer from signal loss if you force it around a sharp corner.

Corning’s ClearCurve®, on the other hand, is a bend-insensitive fiber (BIF) built to the G.657 standard. It has a clever design—an optical trench that acts like a guardrail for the light signal. This keeps the light from leaking out, even when the cable is bent around tight corners. That's why it's the perfect choice for crowded spaces like data centers and Fiber-to-the-Home (FTTx) drops where sharp bends are just part of the job.

Can I Splice Standard Singlemode Fiber to Corning Bend-Insensitive Fiber?

Absolutely. Splicing a standard G.652.D singlemode fiber to a bend-insensitive one like ClearCurve® is not only possible but also a very common practice. Corning knew network operators would need to connect new fiber to the massive amount of existing G.652.D infrastructure, so they designed their G.657.A series fibers to be fully backward-compatible. This allows for seamless network expansions and upgrades.

That said, you have to be precise. There are subtle differences in the mode field diameters of the two fiber types. A sloppy splice can cause a slight signal loss at the connection point.

A modern, well-maintained fusion splicer is your best friend here. Following industry best practices is crucial for creating a solid, low-loss connection between these different fiber generations. For any link that really matters, there's no cutting corners on this step.

Why Is Sourcing From an Authorized Corning Distributor Important?

Buying from an authorized Corning distributor is the only surefire way to protect your network from counterfeit products. It’s your guarantee of product authenticity, quality, and complete traceability all the way from the factory floor to your job site. The market is unfortunately full of look-alike products that don't meet spec, which can lead to frustrating network outages and troubleshooting nightmares down the road.

Going through an authorized channel gives you three critical things:

- Genuine Products: You get the real deal—authentic Corning cables that are built to perform as promised.

- Manufacturer Warranty: Your purchase is backed by Corning's full warranty and access to their technical support.

- Network Integrity: You're building your network on a trusted foundation, avoiding the huge risks that come with unverified, subpar materials.

How Do High-Density Cables Like RocketRibbon Help Network Builds?

High-density cables like RocketRibbon® are game-changers for one of today's biggest challenges: cramming more fiber into less space. These cables use an innovative ribbon design that can be easily split into smaller groups of fibers without needing special tools.

This gives network builders the best of both worlds. You get the speed of mass-fusion splicing that comes with traditional ribbon cables, plus the routing ease of individual fibers. For you, this means you can pack significantly more capacity into existing ducts, which cuts down on expensive construction work and sets your network up for future growth. The smaller, lighter cable also frees up a ton of room in congested conduits and data center pathways, making it a smart choice for any network expansion.

At Southern Tier Resources, we don't just supply components; we build the resilient, high-performance networks that run on them. As your end-to-end telecom infrastructure partner, we bring the expert engineering, construction, and maintenance you need to build for today and scale for tomorrow. Learn how our expertise can power your next project.