From a video conference call that spans continents to the immense data transfers powering the cloud, nearly every digital interaction we have travels through a hidden network of optical fiber. Corning optical fiber cable is the bedrock of this global network, forming the physical superhighways for telecom carriers, ISPs, and data centers. Getting a handle on this technology is the first step to building the kind of reliable, high-speed networks our world now runs on.

Why Corning Fiber Is the Foundation of Modern Networks

At its heart, a fiber optic cable is an incredibly thin strand of glass that sends data as pulses of light. It’s a simple idea with massive implications. This design allows information to travel at nearly the speed of light with remarkably little interference, but the quality of that glass highway is what truly sets it apart.

Corning isn't just another name in the industry; they're the ones who invented the first low-loss optical fiber back in 1970, a breakthrough that made long-distance data transmission practical for the first time. That legacy of innovation is still at the core of their products, which are engineered to handle the extreme demands of today’s digital infrastructure. With data consumption skyrocketing thanks to AI, cloud services, and 5G, a tough, scalable physical network is more critical than ever.

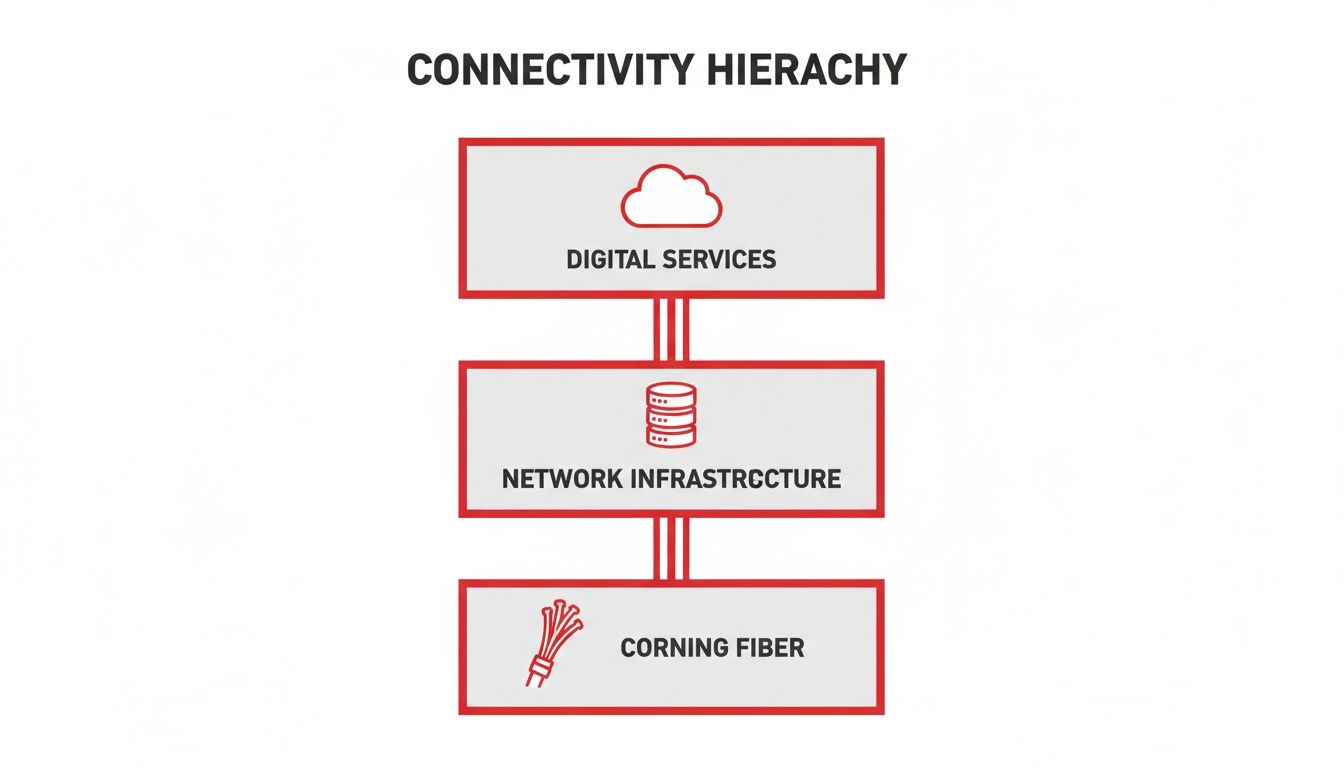

The Unseen Infrastructure for Digital Services

Think about the journey a simple video stream takes. It starts in a massive data center, travels across the country through a long-haul network, gets handed off to a local ISP, and finally arrives at your screen. It's highly likely that every single leg of that journey was carried over Corning optical fiber cable.

The right fiber optic infrastructure isn't just about connecting Point A to Point B. It's about building a resilient, high-capacity foundation that can handle future technologies without needing a complete and costly overhaul.

This guide will walk you through everything you need to know about this essential technology. We'll break down the key differences between fiber types, explain what the various cable constructions are for, and demystify the performance metrics that actually matter. For anyone running a carrier, data center, or ISP, choosing the right fiber isn't just a technical detail—it's a fundamental business decision.

Selecting the right cable ensures your network is ready for tomorrow's bandwidth demands, which helps keep your operational costs in check and delivers the consistent reliability your customers count on. It's all about building a network that’s not just fast today, but ready for whatever comes next.

Single-Mode vs. Multi-Mode Fiber: What’s the Real Difference?

When you get down to the brass tacks of any fiber optic network, the first and most critical decision is choosing between single-mode and multi-mode fiber. It’s a choice that dictates everything that follows—from how far your network can reach to the specific transceivers you’ll need to light it up. Getting this right from the start saves a world of headaches and ensures your network can actually deliver on its promise.

Let's use a simple analogy. Imagine trying to send a signal through a pipe.

Single-mode fiber (SMF) acts like a perfectly straight, incredibly thin pipe with a laser beam shooting down the middle. That single, focused pulse of light travels a direct path with practically nothing to interfere with it. This is why it’s the undisputed king of long-haul networks, effortlessly connecting cities, states, and even continents with minimal signal loss.

On the other hand, multi-mode fiber (MMF) is like a much wider pipe with mirrored walls. Instead of a laser, you’re using a flashlight. The light enters and immediately splits into multiple beams—or modes—that bounce off the walls as they travel. All that bouncing, a phenomenon called modal dispersion, jumbles the signal over distance, making MMF suitable only for shorter runs.

This diagram shows how everything we do online, from cloud computing to simple video calls, ultimately relies on the physical bedrock of network infrastructure, with Corning fiber as the foundation.

It’s a great visual reminder that without a high-quality physical layer like Corning optical fiber cable, none of our modern digital services would be possible.

The OS Standards for Single-Mode Fiber

To keep things consistent, the industry uses "OS" (Optical Single-mode) standards. These classifications give engineers a clear roadmap for selecting the right cable for the job.

- OS1: This is an older, legacy standard you’ll typically find in tight-buffered indoor applications. It works well enough for shorter runs, but its performance is limited to about 10 kilometers due to higher signal loss (attenuation).

- OS2: This is the current champion and the workhorse of modern networks. OS2 fiber is engineered for low water peak performance, which basically means it can handle a wider range of light wavelengths. This versatility makes it perfect for long-haul, metro, and Fiber-to-the-Home (FTTx) networks, capable of pushing data up to 200 kilometers before needing a boost.

For any new network build of significant distance, OS2 is the clear winner. It provides the reach and bandwidth that carriers and ISPs depend on.

The OM Standards for Multi-Mode Fiber

For shorter distances, like inside a data center or across a corporate campus, we turn to multi-mode fiber and its "OM" (Optical Multi-mode) standards. Each new generation has brought significant improvements in bandwidth and distance.

The fundamental difference comes down to the size of the fiber's core. Single-mode has a tiny core, just 9 microns in diameter. Multi-mode fiber has a much larger core—either 50 or 62.5 microns—which is what allows multiple modes of light to travel through it at once.

Let's break down the common OM standards:

- OM1 & OM2: You can spot these legacy cables by their orange jackets. OM1 has a 62.5-micron core, while OM2 has a 50-micron core. They were designed for older, LED-based light sources and top out around 1 Gbps.

- OM3 & OM4: These are laser-optimized multi-mode fibers (LOMMF) with a 50-micron core, easily identified by their aqua jackets. They are built for speed. OM3 can handle 10 Gbps up to 300 meters, while OM4 pushes that same speed out to an impressive 400 meters.

- OM5: The newest player on the block is OM5, also known as wideband multi-mode fiber (look for the lime green jacket). It uses a 50-micron core but is designed to support multiple wavelengths at the same time using a technology called SWDM. This makes it a fantastic choice for new data centers gearing up for 400 Gbps and beyond.

The legacy behind this technology is staggering. Corning, a pioneer in this field since inventing low-loss fiber back in 1970, celebrated delivering its 1 billionth kilometer of optical fiber in 2017. Their fibers achieve incredibly low signal loss—often less than 0.35 dB/km—which is the secret sauce behind today’s massive multi-terabit networks.

To make selection easier, here's a quick comparison of the common fiber standards.

Comparison of Corning Fiber Types OS vs OM Standards

This table breaks down the key differences between the most common single-mode (OS) and multi-mode (OM) fiber standards, helping you align the right cable with your network’s specific needs.

| Standard | Fiber Type | Core Diameter | Typical Application | Max Distance (10 Gbps) |

|---|---|---|---|---|

| OS2 | Single-Mode | 9 µm | Long-Haul, Metro, FTTx | >10,000 meters |

| OM1 | Multi-Mode | 62.5 µm | Legacy LAN (1 Gbps) | 33 meters |

| OM2 | Multi-Mode | 50 µm | Legacy LAN (1 Gbps) | 82 meters |

| OM3 | Multi-Mode | 50 µm | Data Center, Enterprise (10G) | 300 meters |

| OM4 | Multi-Mode | 50 µm | Data Center, Enterprise (10/40G) | 400 meters |

| OM5 | Multi-Mode | 50 µm | High-Speed Data Center (40/100G+) | 400 meters |

Ultimately, the choice between SMF and MMF comes down to your application. A telecom provider building a regional backbone will rely exclusively on OS2 single-mode. A data center architect connecting server racks will find that OM4 or OM5 multi-mode offers the perfect, cost-effective blend of density and performance for those shorter links.

You can explore a variety of these high-performance Corning fiber options right here in our product catalog.

Decoding Different Cable Constructions

Think of the delicate glass fiber as the engine of your network. The cable construction surrounding it is the vehicle—the chassis, armor, and suspension—that protects that engine and determines exactly where it can go. A Corning optical fiber cable is far more than just the glass core; its outer layers are meticulously designed to handle specific environmental challenges.

Getting this choice right is critical. If you pick the wrong construction, you’re setting yourself up for premature failures, expensive repairs, and significant network downtime. Using an indoor-rated cable in an underground conduit, for instance, is a recipe for disaster. It simply doesn't have the moisture and stress protection to survive. The construction is every bit as important as the fiber type itself.

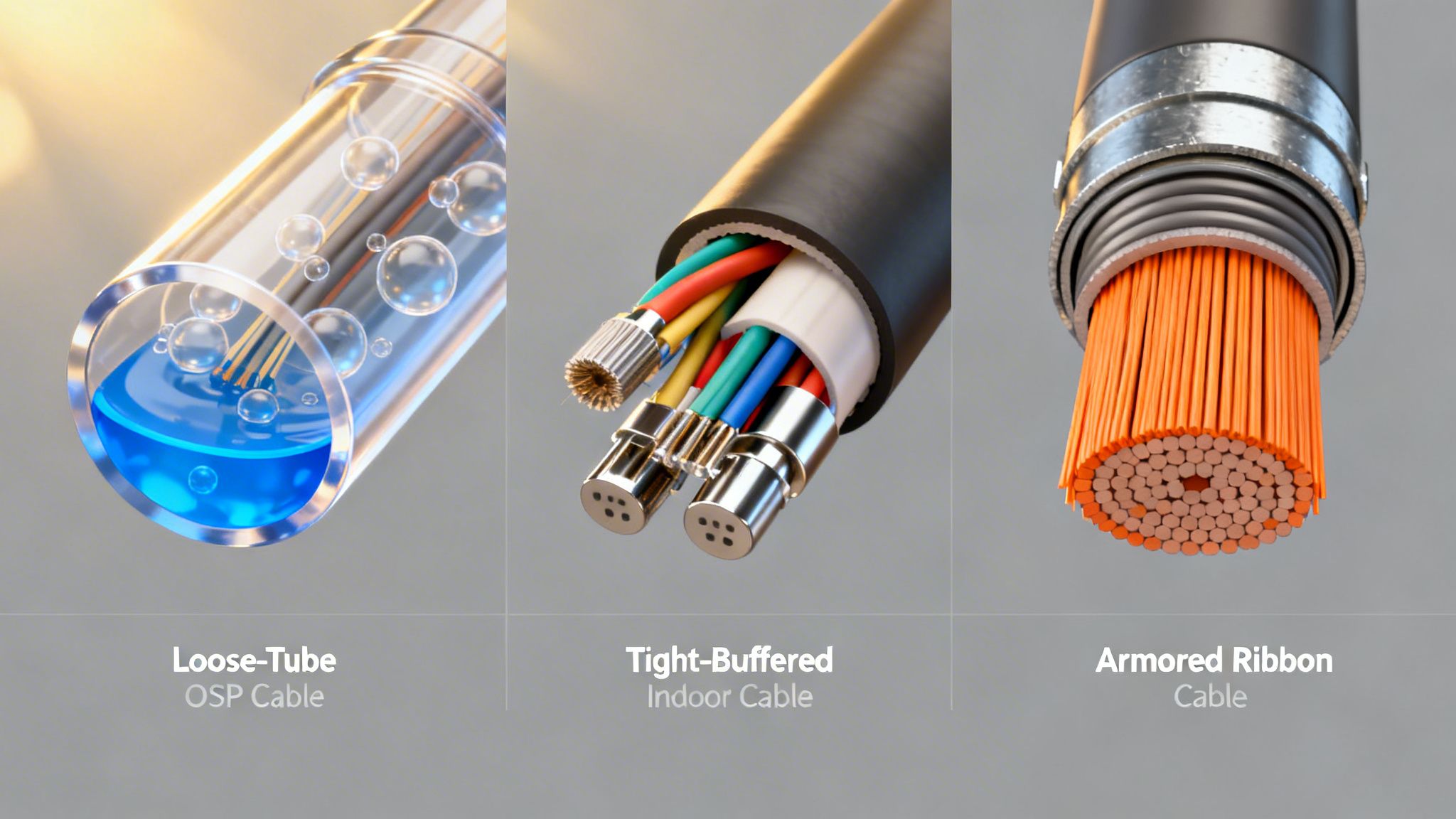

Let's break down the key designs you'll run into, from the rugged cables built for the harshest outdoor conditions to the high-density options made for controlled data center environments.

Outside Plant Cables Built for Survival

Outside Plant (OSP) cables are the frontline soldiers of a fiber network. They are engineered to endure a life of constant environmental assault, from moisture and extreme temperature swings to UV radiation and the physical stress of being buried, pulled through conduits, or lashed to utility poles.

The workhorse of OSP deployments is the loose-tube cable. In this design, the optical fibers float inside a bundle of small, hollow straws called buffer tubes. These tubes are filled with a water-blocking gel or powder, creating a robust first line of defense against moisture.

This "loose" structure also cleverly isolates the fibers from outside forces. As the cable expands and contracts with temperature changes or gets pulled during installation, the fibers have room to move inside the tubes without being stretched or damaged. It's why loose-tube is the go-to standard for long-haul and metro networks.

The primary goal of OSP cable construction is protection and longevity. The design ensures that the fragile glass fibers within remain pristine and functional for decades, regardless of whether they are buried underground or exposed to the elements.

Indoor Cables Optimized for Density and Safety

Once that fiber network makes its way into a building, the rules of the game change. Indoor cables don't face the same environmental threats, but they have to meet strict fire safety codes and be flexible enough for installation in tight spaces like data centers and wiring closets.

Here, the leading design is the tight-buffered cable. Instead of floating in a tube, each fiber is coated with a thicker, 900-micron protective layer. This extra buffering makes the individual fiber much easier for a technician to handle and terminate directly onto connectors, often eliminating the need for a separate fan-out kit. You can dive deeper into the specifics of these cables in our in-depth product guide.

Because they are more flexible but offer less protection against pulling forces, tight-buffered cables are ideal for shorter, protected runs—think patch cords connecting equipment or horizontal cabling running through walls and ceilings.

Specialized Constructions for Unique Challenges

Beyond the two mainstays, Corning has developed a whole range of specialized constructions to solve very specific problems. These innovative designs tackle everything from rodent damage to the ever-increasing demand for higher fiber density in crowded spaces.

Two of the most common specialized types are armored and ribbon cables.

- Armored Cables: When you’re deploying in an area where rodents or crush damage are a real threat, an armored cable is your best bet. These cables add a layer of corrugated steel tape or interlocking armor around the core, making them incredibly resistant to gnawing and physical impact. They are perfect for direct-buried applications or tough industrial settings.

- Ribbon Cables: As data centers and network hubs grow, so does the need to pack more and more fiber into a finite amount of space. Ribbon cables are the answer. Instead of dealing with individual fibers, these cables group 12 or more fibers together into a flat, ribbon-like strip.

This ribbon architecture allows for a massive leap in fiber density. A cable that's the same diameter as a traditional 144-fiber loose-tube cable can suddenly hold 864 fibers or more in a ribbon design. This doesn't just save precious conduit space; it also dramatically speeds up installation time, since a technician can splice an entire 12-fiber ribbon at once with a mass fusion splicer.

Corning is always pushing the envelope on cable design. New developments like their Contour™ Flow cable, which fits double the fiber into the same diameter as older designs, are a direct response to the needs of AI and hyperscale data centers. The right construction isn't just a protective shell; it's a strategic decision that shapes your network's capacity, installation efficiency, and long-term reliability.

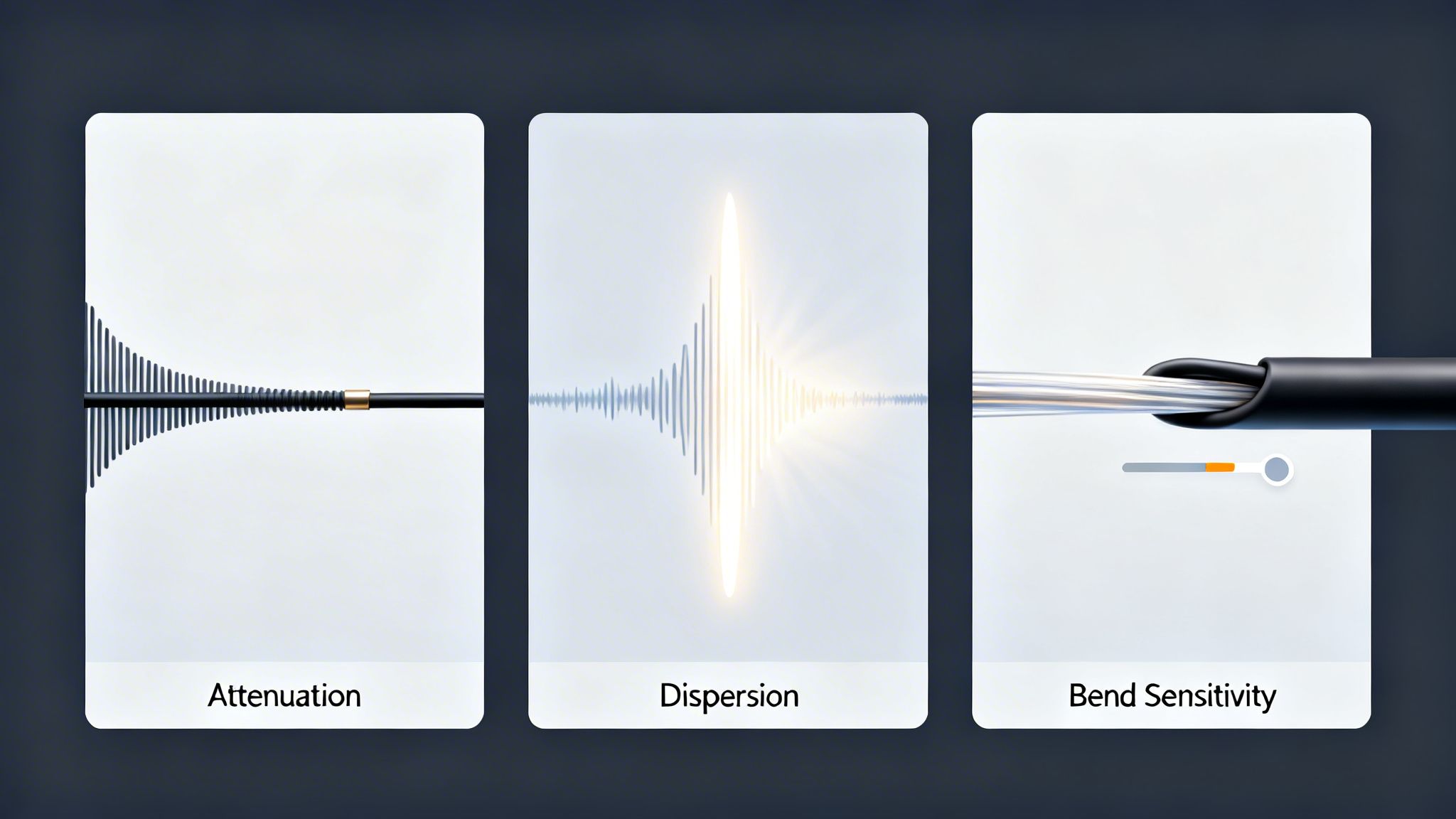

Understanding Key Performance Metrics

When you're choosing a Corning optical fiber cable, you have to look past the basic fiber type and cable construction. The real story of how a network will perform is told by its key metrics—the specifications that define its efficiency and reliability. These aren't just abstract numbers on a data sheet; they have a direct impact on your business, influencing everything from operational costs to service uptime.

Think of it like evaluating a high-performance engine. You wouldn't just look at its size. You’d dig into its horsepower, torque, and fuel efficiency. For optical fiber, the equivalent metrics are attenuation, dispersion, and bend sensitivity. These are what tell you the cable's true capabilities out in the field.

These factors ultimately determine how clean, strong, and fast your data signal is when it gets from point A to point B, whether that’s across a data center or across the country.

Attenuation: The Enemy of Distance

In simple terms, attenuation is the gradual loss of signal strength as light travels down the fiber. Imagine shouting to someone across a huge field—the farther they are, the fainter your voice gets. That's exactly what happens to the light pulse in a fiber optic cable. We measure this signal loss in decibels per kilometer (dB/km).

A lower attenuation value is always what you want. For long-haul carriers, this is a massive economic consideration. A fiber with lower attenuation, like one of Corning's advanced single-mode options, lets the signal travel significantly farther before it needs a boost from an expensive amplifier. Fewer amplifiers mean less capital spending upfront and lower operational costs for power and maintenance down the road.

Dispersion: Signal Distortion Over Time

If attenuation is about the signal getting weaker, dispersion is about it getting sloppier. As a pulse of light travels down the fiber, different components of the light can arrive at slightly different times. This causes the initially sharp pulse to spread out and become blurry.

When the distortion gets bad enough, the receiving equipment can no longer tell one pulse from another, which leads to bit errors and corrupted data. While there are a few types of dispersion, the main thing to know is that it’s what ultimately limits a fiber’s bandwidth and reach. This is precisely why advanced fibers are engineered to fight these effects, ensuring a crisp signal for networks pushing 400G and beyond.

Understanding these performance metrics allows network architects to move beyond the spec sheet. It enables them to predict real-world reliability, calculate the total cost of ownership, and build a network that is both efficient today and scalable for tomorrow.

The demand for this level of performance is exploding. Corning's Optical Communications segment recently pulled in $1.56 billion in revenue in a single quarter, a 41% jump year-over-year, largely thanks to massive investments from enterprise networks and data centers. You can find more details on this growth over at Nasdaq.com.

Bend Sensitivity: A Practical Measure of Resilience

Finally, there’s bend sensitivity, which measures how much signal loss occurs when a fiber is physically bent. This is a huge deal in the real world, where cables are constantly being routed through tight conduits, crowded splice enclosures, and packed server cabinets. A fiber that's too sensitive will literally leak light when bent too sharply, causing major signal loss and even network outages.

This is an area where Corning’s engineering really shines. Their bend-insensitive fibers, like the SMF-28® Ultra fiber, are designed to keep the signal locked in even with very tight bend radii. For installers, this practical feature provides a vital safety margin, ensuring the network remains reliable long-term, even in the most cramped and chaotic environments. A less bend-sensitive Corning optical fiber cable is simply more forgiving and resilient, helping you avoid those hard-to-diagnose service calls.

How To Choose The Right Corning Cable

When it comes to selecting the right Corning optical fiber cable, there isn't a single "best" answer. The real goal is to match the right technology to the specific job at hand. Think of it as a strategic decision, one that needs to balance immediate performance needs, the physical environment, and your network's future growth. Nailing this choice upfront saves you from expensive overhauls down the road and ensures your network is ready for whatever comes next.

The first move is always to get a crystal-clear picture of your application. Are you engineering a long-haul network that stretches between cities? Building out a dense fiber ring in a metro area? Or are you deploying a Fiber-to-the-Home (FTTx) network to connect local subscribers? Each of these scenarios puts very different stresses on the cable and the glass inside. A cross-country backbone, for instance, is all about minimizing signal loss, while a congested urban build demands a tough, compact cable that can be pulled through crowded conduits.

To get there, you need a solid framework—a checklist of critical questions that will systematically narrow the field and point you toward the perfect fit for your performance targets, budget, and operational reality.

Assessing Your Deployment Environment

The physical world your cable will live in is the most critical factor driving your choice of construction. An indoor-rated cable won't last a season outdoors, and using a heavy-duty Outside Plant (OSP) cable for a simple run inside a building is just throwing money away. You have to walk the entire proposed route, from start to finish, and map out every challenge that cable will face over its decades-long service life.

Start by considering these key environmental factors:

- Underground vs. Aerial: Is the plan to bury the cable directly, pull it through existing conduit, or string it up on utility poles? Direct-buried cable absolutely requires armoring to protect against crushing pressure and rodents. Aerial runs, on the other hand, need high tensile strength and UV-resistant jackets to survive years of wind, ice, and direct sunlight.

- Indoor Spaces: Once you're inside a building, fire safety codes are the law of the land. Cables must carry the proper fire rating—either plenum for air-handling spaces like drop ceilings or riser for vertical shafts between floors. These ratings are non-negotiable and ensure the cable jacket won't release toxic fumes in a fire.

- Transitional Routes: Many networks don't live in just one environment. A common path runs from an OSP manhole straight into a data center. For these situations, an indoor/outdoor cable is a game-changer. It eliminates the need for a splice point right at the building entrance, which saves time, money, and a potential point of failure.

Choosing the right cable construction is the foundation of a reliable network. You're selecting a design that offers bulletproof protection from the specific threats of its environment, effectively safeguarding those fragile glass fibers for decades of service.

Matching Fiber Type to Network Scale

After you've locked in the right cable construction, the focus shifts inward to the fiber itself. As we covered earlier, the choice between single-mode and multi-mode fiber really comes down to two things: distance and bandwidth. Your network’s physical scale will make this decision pretty clear.

Take a rural ISP building a new FTTx network across a wide territory. They will, without question, use OS2 single-mode fiber. Its ability to push massive bandwidth over many kilometers with almost no signal degradation is exactly what's needed to serve a spread-out customer base. They’d likely spec a rugged, armored loose-tube Corning optical fiber cable to handle the rough conditions of direct burial.

Now, flip the script to a financial firm outfitting a new data center. Their needs are completely different. Here, every connection—from servers to switches to storage arrays—is incredibly short, usually well under 100 meters. This is the perfect use case for OM4 or OM5 multi-mode fiber. Housing it in a high-density, plenum-rated ribbon cable provides all the bandwidth they could need for internal traffic, saves precious space in cable trays, and dramatically speeds up installation with mass fusion splicing.

This kind of scenario-based thinking ensures the cable you choose isn't just a technical match, but is truly optimized for the job you need it to do, giving you the best possible return on your investment.

Expert Installation and Network Maintenance

You can have the best Corning optical fiber cable in the world, but its performance is only as good as the team that installs it. The true potential of a fiber network is unlocked during deployment, where expertise and an almost obsessive attention to detail make all the difference. Professional installation isn’t just about pulling cable from point A to point B; it’s about building a foundation for long-term reliability and getting the most out of your infrastructure investment.

This process starts long before the first reel of fiber arrives. It involves careful route planning to navigate potential hazards and meticulous cable handling to prevent the tiny, invisible microbends or physical stresses that can quietly degrade signal quality over the years. Every step, from unspooling to final placement, is calculated to protect the delicate glass fibers inside.

At the heart of any high-performance network is the quality of its connections. This is where the skill of a technician truly shines.

The Art of Precision Fusion Splicing

A fusion splice is the act of melting two optical fibers together with an electric arc to form a single, continuous strand. The goal is to create a bond so perfect that light passes through with virtually zero reflection or signal loss. A bad splice, on the other hand, is a hidden point of failure that introduces signal degradation and can be a nightmare to track down later.

An experienced technician can consistently achieve splice losses well below 0.05 dB—a nearly flawless connection that preserves the integrity of your data. Hitting that number isn’t just about having the right machine; it requires a deep understanding of fiber geometry, cleanliness, and how to adapt to environmental conditions on the fly.

A professional installation ensures that every component, from the cable itself to the final connection point, performs exactly as engineered. It’s the difference between a network that merely functions and one that operates at its peak potential for decades.

This dedication to quality goes beyond the splice itself. It includes properly managing the spliced fibers within enclosures, respecting the cable’s bend radius limits, and creating detailed documentation. These practices are the hallmarks of a professional job, preventing future problems and making life much easier when it comes to maintenance or troubleshooting.

Validating Performance with Advanced Testing

Once everything is physically connected, the work is far from over. The only way to be certain the network meets its performance goals is through rigorous testing. The undisputed king of this process is the Optical Time Domain Reflectometer (OTDR).

Think of an OTDR as a kind of radar for fiber optic cable. It sends a high-powered pulse of light down the line and then analyzes the light that reflects back. This incredibly powerful tool allows us to:

- Pinpoint Fault Locations: It can identify the exact location of a break, a sharp bend, or a subpar splice with pinpoint accuracy.

- Measure Signal Loss: It quantifies the total signal degradation (attenuation) across the entire link and measures the specific loss at every single splice and connector.

- Verify Overall Quality: The final OTDR trace acts as a "birth certificate" for that network segment, providing a detailed performance baseline that's invaluable for future reference.

Proactive maintenance, built on this initial data, is what keeps a network running smoothly and ensures operational continuity. Partnering with an experienced team like Southern Tier Resources gives you access to the specialized skills and equipment required for flawless execution. You can learn more about our commitment to quality in our guide to insulation and protection standards.

Common Questions, Answered

When you're dealing with something as critical as network infrastructure, questions are a good thing. They lead to better decisions. Let's tackle a few of the most common ones we hear about Corning optical fiber cable.

What’s the Big Deal With Corning Fiber, Anyway?

It really comes down to history and performance. Back in 1970, Corning invented the first practical, low-loss optical fiber, and they’ve been setting the standard ever since. It’s not just a brand name; it’s a mark of serious engineering.

Corning fibers are famous for their incredibly low attenuation, which means your signal stays stronger over longer distances. They also lead the pack in bend insensitivity—a crucial feature when you’re pulling cable through tight conduits or crowded server racks. This isn't just about specs on a datasheet; it translates directly into a more reliable network and fewer headaches down the road.

So, Is Single-Mode Just Better Than Multi-Mode?

Not necessarily. It's like asking if a semi-truck is better than a sports car—it completely depends on what you need to do.

Single-mode fiber is your long-haul champion. Its tiny core is built for sending a single, focused beam of light over massive distances, which is why it's the go-to for telecom carriers and anyone building out a large-scale FTTx network.

Multi-mode fiber, with its larger core, is perfect for shorter runs. It's the workhorse inside data centers and across corporate campuses, connecting servers and switches in a way that's both effective and more budget-friendly for those distances.

Here’s a piece of advice we always give: When in doubt, pull more fiber than you think you need. The cost of adding a few extra strands to a cable during manufacturing is tiny compared to the expense of trenching and installing a whole new cable a few years from now.

Think about the long game. Choosing a modern fiber standard like OS2 for single-mode or OM5 for multi-mode gives your network the headroom to handle future bandwidth demands. This kind of planning saves a lot of money and disruption later on.

Building a network that lasts requires more than just good materials; it requires a partner who understands how to put them together. The team at Southern Tier Resources has the hands-on experience to engineer and install your fiber infrastructure right the first time. Visit our website to learn how we can help.