Data center cable management isn't just about keeping things tidy. It's the entire system of hardware and best practices you use to organize all the power, data, and fiber optic cables that keep a facility running. The end game? A highly structured environment that boosts airflow, makes maintenance a breeze, and locks in maximum uptime and scalability.

Why Organized Cables Are a Data Center’s Secret Weapon

It's tempting to think of cable management as glorified housekeeping, but that's a huge mistake. In reality, it's the very foundation of your data center's performance, safety, and reliability. As rack densities skyrocket thanks to AI and cloud computing, messy cabling goes from a minor annoyance to a major operational risk. That tangled mess of cables—what we all call "spaghetti"—does more than just look bad; it actively sabotages your infrastructure's efficiency.

This guide treats cable management as what it truly is: a strategic necessity. It's how you optimize airflow, sidestep expensive downtime, and ensure your facility is ready for whatever comes next. Think of it as the secret to operational excellence in any high-stakes IT environment.

The True Cost of Disorganized Cabling

Letting cables run wild creates a domino effect of problems that go way beyond looks. The first and most immediate hit is to your thermal management. Messy cables block the pathways for cool air to get to your equipment and prevent hot air from getting out. This creates hotspots, which means your cooling systems have to work overtime, burning through energy and money.

On top of that, a disorganized rack turns routine maintenance into a technician's worst nightmare. What should be a simple job—like tracing and replacing a bad cable—can stretch from minutes into hours. This blows up your Mean Time To Repair (MTTR) and dramatically increases the chances of someone making a mistake that takes down a critical service.

When every minute of downtime can cost thousands of dollars, the initial investment in a structured cabling system pays for itself by safeguarding against these preventable failures. Organized infrastructure is a direct investment in business continuity.

A Market Reflecting Critical Demand

You don't have to take my word for it—just look at the market. The data center cable management sector is booming, projected to be worth USD 7.7 billion in 2025 and on a trajectory to hit USD 18.1 billion by 2035. This explosive growth is being driven by the non-stop expansion of cloud services and the demand for faster connectivity, where the slightest hiccup caused by poor cabling can have massive consequences. You can dig deeper into this market forecast and its drivers over at Future Market Insights.

Ultimately, putting a solid data center cable management solution in place brings a host of benefits that directly impact your bottom line:

- Improved Airflow and Cooling Efficiency: Clean cable runs mean clear air paths. This keeps equipment from overheating and slashes your cooling costs.

- Enhanced Maintenance and Accessibility: Technicians can get in and out quickly and safely, identifying and servicing gear without accidentally unplugging something next to it.

- Increased Reliability and Uptime: By reducing physical strain on cables and preventing accidental disconnects, you minimize the risk of network failures and unexpected downtime.

- Future-Proof Scalability: A well-designed system makes adding new hardware much faster and easier, allowing you to grow and adopt new tech without a major overhaul.

Exploring Core Data Center Cabling Hardware

Let’s move from theory to the physical world. The real-world effectiveness of any data center cable management strategy comes down to the hardware you choose. These components are the literal building blocks of an organized, efficient, and scalable infrastructure. It helps to think of them not just as pieces of metal and plastic, but as the essential skeleton that supports every single byte flowing through your facility.

The foundation of this whole framework is the network of pathways that guide cables from point A to point B. Just like a city's road system, these pathways ensure data traffic flows smoothly and predictably, preventing the digital equivalent of a frustrating traffic jam. Getting to know these core components is the first step toward building a data center that’s robust and, most importantly, manageable.

The Main Arteries: Cable Trays and Ladder Racks

The primary "highways" for routing large bundles of cables are cable trays and ladder racks. These systems are designed to create dedicated, protected routes that get cables off the floor and out of the way, forming the absolute backbone of your cabling plant. While people sometimes use the terms interchangeably, they do have slightly different jobs.

- Ladder Racks: With a simple design of two side rails connected by rungs, ladder racks are the workhorses for heavy-duty power cables and thick bundles of copper data cables. Their open structure is great for easy access and lets heat dissipate naturally.

- Cable Trays: These come in a few different flavors, including solid bottom, ventilated, and wire mesh (which you'll often hear called basket trays). They provide more continuous support, which makes them perfect for routing huge quantities of smaller data cables, especially delicate fiber optics that can be damaged by sagging.

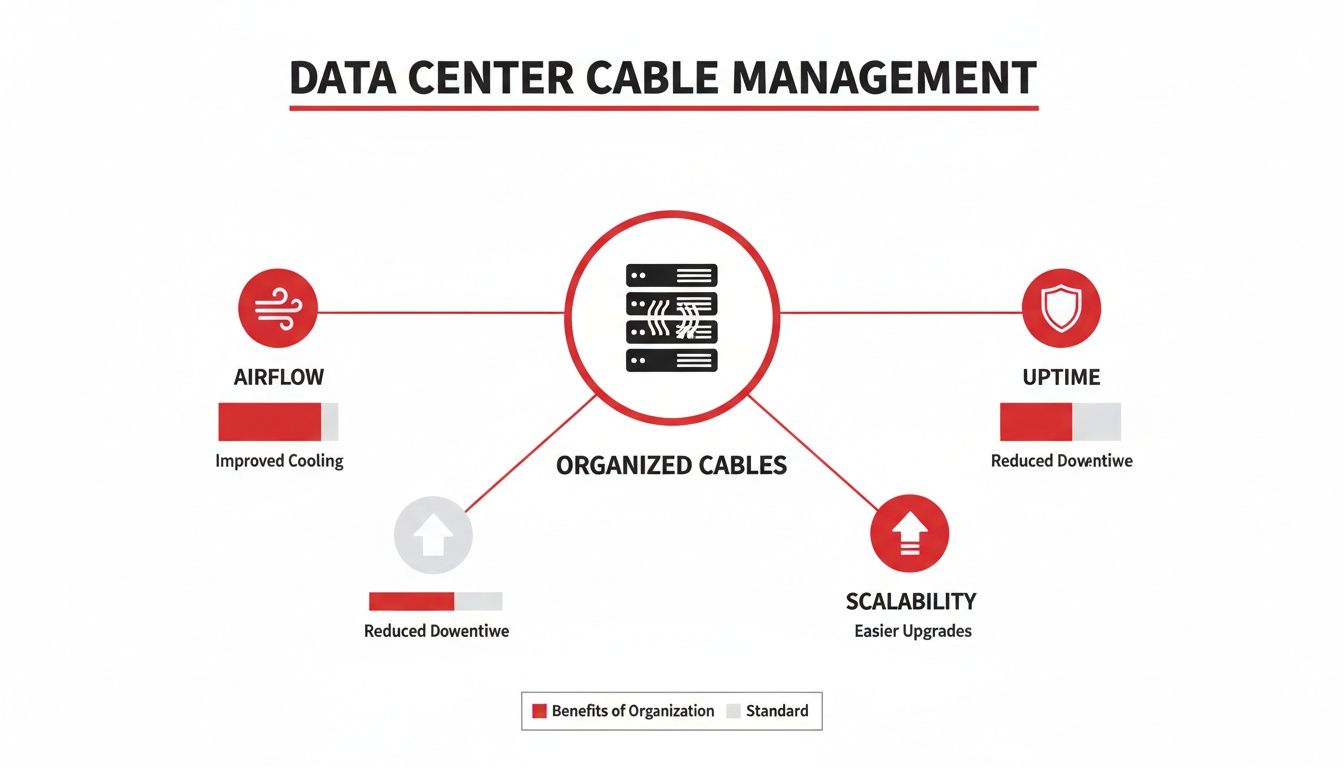

The infographic below really drives home how using organized hardware solutions like these directly boosts key performance metrics like airflow, uptime, and your ability to scale.

This visual highlights a critical truth: thoughtful cabling hardware isn't just about making things look tidy. It's a strategic investment in the fundamental operational health of your data center.

Overhead vs. Underfloor Pathways

Once you’ve settled on using trays or ladders, the next big question is where to put them. The two main schools of thought are overhead and underfloor, and your choice has massive implications for airflow, cooling efficiency, and day-to-day accessibility.

Overhead pathways have become the gold standard for most new data center builds. By suspending trays and racks from the ceiling, you leave the subfloor completely clear for cold air distribution—a non-negotiable factor in today's high-density computing environments. This approach also makes a technician's life much easier, as they can see and get to cables without having to lift heavy, awkward floor tiles.

Underfloor pathways, often found in older facilities built on raised floors, involve running all the cabling beneath the floor tiles. While this does a great job of hiding the cables from view, it can create major airflow obstructions if it isn't managed with near-perfect discipline. A "rat's nest" of cables under the floor can literally block the path of cold air, leading to equipment hotspots and forcing your cooling systems to work overtime. When planning your pathways, it's also essential to consider the power infrastructure, including the details of a three-phase power installation, which is crucial for supporting high-density racks.

The table below breaks down the key differences between these two approaches.

Comparison of Cable Management Pathway Solutions

Here's a side-by-side look at how overhead and underfloor cabling pathways stack up against each other, comparing the critical factors that influence data center design and long-term operations.

| Factor | Overhead Systems (Ladder Racks/Trays) | Underfloor Systems (Raised Floors) |

|---|---|---|

| Cooling Efficiency | Excellent. Keeps the subfloor clear, allowing for unobstructed cold air delivery to server intakes. | Can be problematic. Poorly managed cables can create "dams" that block airflow, leading to hotspots. |

| Accessibility | High. Technicians can easily see and access cables without disrupting operations or lifting floor tiles. | Low. Requires lifting heavy floor tiles, which is time-consuming and can disrupt airflow patterns. |

| Scalability | Very high. Easy to add new trays or pathways to accommodate growth without major structural changes. | Moderate. Adding new cabling can be difficult and may require re-routing existing bundles to maintain airflow. |

| Initial Cost | Generally lower installation cost compared to building a full raised-floor environment. | Higher initial cost due to the structural requirements of the raised floor system itself. |

| Best For | Modern, high-density data centers, hot/cold aisle containment, and environments prioritizing cooling. | Older facilities, low-density environments, or specific designs where aesthetics are a primary concern. |

Ultimately, the choice depends on your facility's design, but for new builds, the advantages of overhead pathways in cooling and maintenance are hard to ignore.

In a raised-floor environment, every unsealed opening and every bundle of cable blocking an air path can reduce cooling efficiency by creating bypass airflow, effectively stranding cooling capacity and driving up energy costs.

Managing Cables Inside the Rack

Now, let's zoom in from the facility-wide highways to the "local roads" inside your individual server racks and cabinets. This is where precision becomes paramount. Vertical and horizontal cable managers are the unsung heroes that prevent connector strain, maintain the proper bend radius for cables, and stop your cabinets from descending into a tangled mess.

- Horizontal Managers: These are usually 1U or 2U rack-mounted units with finger ducts or D-rings that guide patch cords cleanly from switches to patch panels.

- Vertical Managers: Installed along the sides of the rack, these create a dedicated channel for routing large cable bundles up and down, keeping them organized and—critically—out of the way of hot air exhausting from your equipment.

For specialized connections like fiber optics, you need dedicated hardware. Fiber enclosures and cassettes provide a secure, clean environment for delicate terminations. This not only protects signal integrity but also makes future adds, moves, and changes a thousand times simpler. To get a better grasp of the principles behind these installations, feel free to explore our in-depth guide on https://southerntierresources.com/network-cabling-infrastructures/. All of these pieces have to work together to create a complete and effective cable management solution for your data center.

Putting Standards to Work for Flawless Execution

Great data center cable management isn’t magic—it’s a discipline. It’s built on a foundation of proven industry standards that act as a universal blueprint for a resilient, reliable, and maintainable infrastructure. When you follow these guidelines, you transform potential chaos into a model of operational efficiency, ensuring every cable is an asset, not a liability.

This isn’t just about making things look tidy. Following a clear playbook is a strategic move that directly boosts your facility's cooling efficiency, uptime, and ability to grow. You systematically eliminate the variables that cause outages, creating an environment where troubleshooting and upgrades are straightforward and predictable.

Prioritizing Airflow and Thermal Management

One of the first things you’ll notice from standards-based cable management is a massive improvement in airflow. Messy, disorganized cables are like dams in a river, blocking the pathways designed to bring cold air to your equipment and vent hot air out. This creates dangerous hotspots and forces your cooling systems to work overtime, burning through energy just to keep temperatures stable.

Best practices are clear: cable pathways, whether overhead or underfloor, must be planned to minimize obstruction. In a raised-floor environment, for example, running cable trays parallel to the airflow direction is a simple rule with huge impact. It prevents air turbulence and ensures cool air gets exactly where it's needed most—the server intakes.

A classic mistake we see is overstuffing cable trays. A tray packed to 100% capacity can choke airflow by more than 50%, essentially wrapping your cables in an insulating blanket that traps heat and threatens equipment health.

The Critical Separation of Cable Types

Another non-negotiable rule is keeping power, copper data, and fiber optic cables physically separate. Running high-voltage power lines right next to sensitive data cables is asking for trouble. The electromagnetic interference (EMI) from power cables can easily corrupt data signals, causing network errors and performance dips that are a nightmare to diagnose.

The standards provide a simple, effective solution:

- Keep Your Distance: Use separate pathways for power and data cables whenever you can.

- Use Protection: If they must run near each other, use shielded copper cabling (STP) to guard against EMI.

- Cross at 90 Degrees: If power and data lines absolutely have to cross, make sure they do it at a right angle to minimize the interference zone.

This intentional separation is fundamental to signal integrity and network reliability. It's a foundational step that will save you countless hours of frustrating troubleshooting later on.

Mastering Slack Management and Labeling

Getting cable slack right is a bit of an art. You need just enough extra length to handle future moves, adds, and changes without creating a tangled mess. Too much slack just adds to the clutter and blocks airflow; too little means you can't perform basic maintenance without running a whole new cable. The sweet spot is a neat, manageable service loop, properly secured and tucked out of the way.

Just as critical is a logical and comprehensive labeling system. The TIA-606 standard for administration gives you a solid framework for creating unique IDs for every single component, from patch panels down to individual ports. A well-executed labeling plan is worth its weight in gold during an outage.

When a server dies at 2 a.m., clear labels allow a technician to trace the entire connection in minutes, not hours. Instead of manually untangling one cable from a bundle of hundreds, they can pinpoint the problem and fix it fast, drastically reducing your Mean Time To Repair (MTTR). For a deeper look at these guidelines, you can explore the core principles of data center cabling standards that inform these practices.

Documentation as Your Infrastructure Bible

Finally, meticulous documentation pulls everything together. Your "as-built" diagrams, cable run sheets, and port maps are the single source of truth for your physical infrastructure. They ensure everyone on your team is on the same page and make planning for future growth far more efficient. In fact, solid cable management and standards are essential for any major facility change; understanding these data center migration best practices is key to a smooth transition.

The market certainly recognizes the value of this structured approach. The global data center cabling market, valued at USD 7.1 billion, is projected to grow at a strong 8.9% CAGR from 2025 to 2034. This trend highlights just how vital structured cabling is for supporting the explosive demand for data driven by AI and cloud computing. You can find more details about this market's rapid expansion on gminsights.com.

Choosing the Right Cable Management Solution

When it's time to select a data center cable management solution, looking at the upfront hardware cost is just the tip of the iceberg. I've seen it happen time and again: a seemingly "cheap" solution ends up costing a fortune down the road in maintenance headaches, troubleshooting nightmares, and stifled growth. A smart investment requires a strategic approach, one that lines up each option with your facility’s unique operational needs and long-term goals.

Forget the sticker price and start thinking in terms of Total Cost of Ownership (TCO). TCO gives you the full picture. It includes the initial purchase, yes, but also installation, ongoing upkeep, and—most importantly—the hidden cost of downtime that stems from poor cable management. The right choice adds value over its entire lifecycle, not just on the day you buy it.

Aligning Solutions with Scalability and Density

Your data center is a dynamic environment, not a museum piece. It has to evolve to handle new technologies and ever-increasing demand. That’s why the first real test of any cable management system is scalability. Will it support your rack density today and handle the inevitable jump in bandwidth and connections tomorrow?

A system that’s perfectly fine for your 10G network could become a tangled, performance-killing bottleneck when you’re ready for 400G. Think about how easily you can perform adds, moves, and changes. A system designed with accessible pathways and modular parts can turn a weekend-long overhaul into a quick, targeted fix. That kind of flexibility is what separates a good infrastructure from a great one.

The global demand for this kind of forward-thinking infrastructure is staggering. The data center wire and cable market is expected to explode from USD 20.91 billion in 2025 to USD 54.82 billion by 2031. This growth is being driven by hyperscalers rolling out massive, gigawatt-scale facilities that demand incredible efficiency. You can get more details on this global market growth on datainsightsmarket.com.

Prioritizing Maintainability and Uptime

In the data center world, every minute of downtime has a price. An intelligent data center cable management solution is one of your strongest lines of defense against those preventable outages. When something goes wrong, your team’s ability to fix it fast comes down to one thing: how easily they can find, access, and swap out the failing component.

This is where your Mean Time To Repair (MTTR) comes into play. A messy, unlabeled spaghetti junction of cables can turn a five-minute fix into a five-hour crisis, sending your MTTR through the roof. On the other hand, a logically organized, clearly labeled system allows a technician to trace a connection in seconds and make repairs with surgical precision. The result is minimal disruption.

A cable management strategy should be evaluated on a simple principle: Does it make a technician's job easier or harder during a high-pressure outage? The answer directly correlates to your facility's resilience and operational continuity.

As you weigh your options, ask yourself these critical questions:

- Accessibility: How fast can a technician get to a specific cable without disrupting everything around it?

- Identification: Does the system support clear, standards-based labeling that makes tracing a connection foolproof?

- Protection: Is the hardware actually protecting cables from physical stress, sharp bends, and other damage that leads to failure?

Making the Final Decision

At the end of the day, the right choice is a careful balance of cost, scalability, and maintainability. You're not just investing in hardware; you're investing in operational efficiency and future-proofing your facility. A solution that slashes your MTTR, simplifies upgrades, and supports higher densities will pay for itself by maximizing uptime and ensuring your data center can grow without costly, disruptive overhauls. Choose the system that empowers your team to work smarter, not harder.

Your Partner for End-to-End Infrastructure Success

Pulling off a sophisticated data center cabling project takes a lot more than just good hardware. It requires a true partner—a team of experts who can take a complex blueprint and turn it into a high-performance reality. A successful deployment is all about seamless execution, from the first design sketches and engineering plans all the way through construction, fiber splicing, and final testing.

This holistic approach is critical. It makes sure every single piece of the puzzle, from the cable pathways to the power distribution, works in perfect harmony. Without a unified strategy, projects can easily fall prey to scope creep, blown budgets, and painful delays. Having a single, accountable partner closes the communication gaps and coordination headaches that plague projects juggling multiple vendors, leading to a much smoother and more efficient build.

From Blueprint to Live Environment

A genuine turnkey provider doesn't just show up for one part of the job; they manage the entire lifecycle of your infrastructure build-out. With over two decades of hands-on experience fitting out both enterprise and hyperscale data centers, a seasoned partner knows the immense pressure to deliver on time and to the absolute highest quality standards. This is where deep expertise becomes your most valuable asset.

The process always starts with a deep dive into your specific needs, which informs a detailed plan that accounts for every possible variable.

- Initial Design and Engineering: We work side-by-side with your team to architect a solid plan that not only meets today's demands but also has the flexibility for future growth.

- Meticulous Construction: We deploy skilled crews who live and breathe the unique requirements of mission-critical environments, ensuring every installation is done by the book.

- Precision Fiber Splicing and Testing: We guarantee every connection delivers peak performance and rock-solid reliability through rigorous, standards-based testing and validation.

This comprehensive oversight is what turns a vision on paper into a scalable, resilient infrastructure ready to support your most critical operations.

The real value of a turnkey partner isn't just in the final product, but in the certainty of the process. It's the confidence that comes from knowing an experienced team is managing every detail to mitigate risk and guarantee operational continuity.

Why Partnership Matters for Scalability

Choosing the right implementation partner is just as critical as selecting the right hardware. An experienced team ensures your data center cable management solutions are not only installed correctly but are also optimized for long-term maintainability and easy scalability. This forward-thinking approach prevents future bottlenecks and simplifies upgrades, which has a direct, positive impact on your total cost of ownership.

By entrusting your project to a team with a proven track record, you’re not just building a data center—you're securing a foundation built for reliability.

Ready to see how a dedicated team can elevate your next project? Learn more about the advantages of working with top-tier cable contractor companies and discover how expert partnership drives infrastructure success. When you're ready to build an infrastructure that is both powerful today and prepared for tomorrow, engaging a turnkey provider is the most strategic decision you can make.

Common Cable Management Questions Answered

Even the best-laid plans run into real-world questions on the data center floor. When you're in the middle of a major cabling project, these are the kinds of practical issues that pop up time and again. Getting them right is what separates a smooth, professional installation from a future maintenance headache.

So, let's tackle some of the most frequent questions we hear from teams in the field.

What's the Real Deal with Cable Tray Fill Ratios?

This one comes up on almost every project. It's always tempting to pack as much as you can into a cable tray to save space, but the standards are there for a very good reason. The industry best practice, backed by guidelines like ANSI/BICSI 002, is to never go past 50% fill capacity.

That number isn't just arbitrary. When you overfill a tray, you choke off airflow and trap a ton of heat right where you don't want it—around your mission-critical cables. It also makes pulling a new line or fixing a bad one a nightmare. Think of that extra space as breathing room for your infrastructure, giving it the capacity to grow and making it easier to manage down the road.

Do Fiber and Copper Really Need Different Management?

Absolutely, yes. While you want both to be neat and tidy, that's where the similarities end. Fiber optic cabling is incredibly sensitive and needs to be handled with a different mindset.

- Bend Radius: This is the big one. Fiber is made of glass, and if you bend it too sharply, you'll create microfractures that kill your signal. Specialized fiber raceways and managers are built with gentle, sweeping corners specifically to prevent this.

- Connector Protection: The ends of fiber connectors are notoriously easy to contaminate with dust or damage from a simple bump. That's why dedicated enclosures and cassettes are non-negotiable for keeping them clean and safe.

- Cable Strain: Copper is definitely tougher, but you still need managers that prevent the cable's weight from yanking or kinking the connection at the patch panel or switch port.

Separating power, copper, and fiber is standard practice for avoiding interference, but the physical handling requirements are just as important. They are fundamentally different beasts.

Proper cable management is proactive, not reactive. The goal is to engineer an environment that prevents problems like signal degradation and overheating before they ever have a chance to cause an outage.

How Much Does Cabling Actually Block Airflow?

This is a tougher one to eyeball, but its impact is huge. While a full-blown Computational Fluid Dynamics (CFD) analysis will give you the most precise data, you can rely on a simple principle: any obstruction messes with air pressure and hurts your cooling.

Here’s a startlingly common example: an unsealed cable opening in a raised floor. A single 6×9 inch floor cutout that is only a quarter full of cables can still allow 22% of the chilled air to completely bypass the servers it was intended for. That's a massive waste of cooling energy.

Simple fixes like brush grommets can seal those gaps and instantly reclaim that stranded cooling capacity. In the same way, making sure your vertical cable managers aren't blocking the back of a server rack is crucial for preventing hot air from getting sucked right back into the server intakes. The entire game is about creating a clean, unobstructed path for air to do its job. It’s a simple discipline that pays huge dividends in thermal efficiency.

At Southern Tier Resources, we don't just talk about best practices—we build them. Our end-to-end services are designed to engineer a data center infrastructure that delivers peak performance, rock-solid reliability, and smart scalability from day one. See how we make it happen at southerntierresources.com.