Think of fiber optic construction companies as the master builders of the digital age. They are the specialized contractors who lay the physical groundwork for our connected world—the superhighways of glass that power next-generation broadband, 5G networks, and the cloud.

These teams handle the entire process, from mapping out the initial route and navigating the maze of permits to the heavy civil work of trenching conduit and the delicate art of splicing glass strands thinner than a human hair. Choosing the right one isn't just a vendor decision; it's a foundational choice for your network's future.

Why Your Choice of Fiber Construction Partner Is So Critical

Selecting a fiber construction partner is one of the most consequential decisions you'll make. This isn't just about digging a trench and pulling cable. It's about finding a true infrastructure partner who understands how to architect the digital highways needed to support 5G, the Internet of Things, and mission-critical broadband.

A top-tier partner doesn’t just pave the road—they engineer the on-ramps, interchanges, and traffic control systems that guarantee your network performs reliably for decades. The right choice directly impacts your project timeline, budget, and long-term network health. The wrong one? That can lead to a cascade of costly rework, damaged infrastructure, and service delays that ripple through your entire business.

The Unstoppable Demand for Bandwidth

The hunger for high-speed connectivity is growing faster than ever, and a few key trends are throwing fuel on the fire:

- Data-Heavy Tech: The explosion of AI, cloud computing, and 4K/8K streaming demands a colossal amount of bandwidth that only fiber can deliver without breaking a sweat.

- 5G & IoT Networks: The 5G revolution and the ever-expanding Internet of Things are completely dependent on a dense fiber backbone to connect cell towers and billions of smart devices.

- Closing the Digital Divide: Major government and private sector investments are underway to bring high-speed internet to underserved urban and rural areas, creating massive construction opportunities.

- Hyperscale Data Center Boom: Cloud giants are building data centers the size of small cities, all of which require diverse, high-count fiber routes to connect to the rest of the world.

This relentless demand means the quality of the physical infrastructure underneath it all has never mattered more. A network built on a shaky foundation is guaranteed to crumble under the weight of future innovation and user expectations.

The sheer volume of work available to fiber optic construction companies is staggering. The global fiber optics market is on a trajectory to nearly double, jumping from an estimated $10.8 billion in 2025 to almost $20.9 billion by 2035.

In fact, the telecom sector alone accounted for about 42% of this market in 2024, a clear indicator of just how much growth is tied directly to the outside and inside plant projects these contractors specialize in. You can explore more insights into this growth in the latest fiber optics market analysis from Precedence Research.

Ultimately, your partner's ability to navigate complex permitting, manage intricate civil work, and execute precise technical tasks is what makes the difference. A skilled, versatile construction company is the bedrock for launching next-generation services on time and on budget, ensuring your network becomes a powerful asset, not a persistent liability.

What Top Fiber Contractors Really Do: A Look at Their Core Services

A full-service fiber project involves much more than just digging trenches and laying cable. The best fiber optic construction companies are really end-to-end project managers, responsible for taking a network from a concept on a whiteboard to a fully lit, high-performance asset. This journey requires a precise sequence of engineering, physical construction, and highly technical execution.

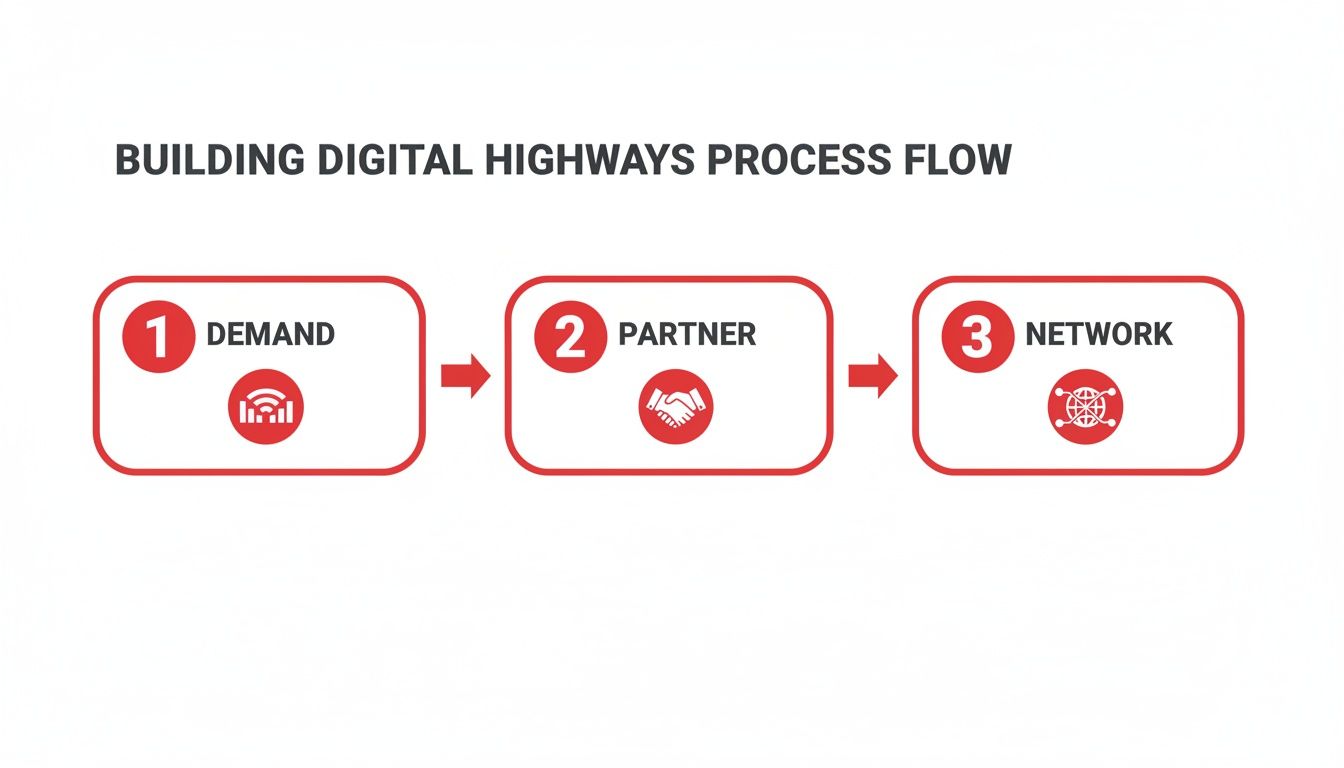

Think of it like building a new national highway system. You don't just send out the paving crews. First, you need surveyors, civil engineers, and logistics experts to map every mile, secure land rights, and prepare the ground. That same depth of planning is critical when you're building the digital highways of tomorrow.

This process moves from identifying real-world bandwidth demand to activating a new network with a partner you can trust.

As the visual shows, a successful network deployment starts long before any ground is broken. It all begins with smart demand analysis and choosing the right partner.

Engineering the Network Blueprint

Before the first shovel ever hits the dirt, a huge amount of engineering work is done to set the project up for success. This is where the project’s route, methodology, and overall viability are hammered out. It’s the architectural blueprint that guides the entire build.

This critical phase usually includes:

- Route Engineering and Design: This is far more complex than just drawing lines on a map. Engineers get out in the field to conduct detailed surveys, identifying the most efficient and cost-effective path. They have to account for terrain, existing utilities, and environmental hurdles.

- Permitting and Right-of-Way (ROW) Acquisition: Navigating the maze of municipal, state, and private approvals is a job in itself. Experienced contractors have teams dedicated to securing permits and negotiating ROW agreements—a process that can easily bring a project to a halt if not handled by experts.

- Make-Ready Engineering: This is all about preparing existing infrastructure for the new fiber. For aerial builds, it means assessing utility poles to ensure they have the space and structural integrity. For underground routes, it involves getting existing conduits ready for new cable.

The Construction Phase: Aerial vs. Underground

Once the plan is locked in, construction begins. The two main approaches—aerial and underground—each have their own pros and cons, and the right choice depends on the environment, budget, and local rules.

A professional contractor will help you weigh the options. For example, aerial construction is typically faster and cheaper because it uses existing utility poles. The downside? It’s more exposed to bad weather and physical damage. On the other hand, underground construction, whether done by trenching or directional boring, offers far better protection and a cleaner look, but it comes with a higher price tag and more disruption at street level. Getting a clear overview of different fiber optic construction methods is the best way to determine which path fits your project’s goals.

Choosing the right construction method isn't just a technical decision; it's a strategic one. It impacts your network's long-term resilience, maintenance costs, and public perception. A seasoned partner provides the data to make an informed choice.

Precision Splicing, Testing, and Final Documentation

The final leg of the journey is where the network truly comes alive. This stage demands immense technical skill, as the work is incredibly precise and has a direct impact on signal quality and reliability.

- Fiber Splicing: This is the delicate art of joining two fiber optic cables. Technicians use high-tech fusion splicers to perfectly align and melt together glass cores that are thinner than a human hair, creating a flawless path for light to travel. It’s a job that requires specialized training, since even a tiny misalignment can cripple the network’s performance.

- Testing and Commissioning: After splicing, every single connection is rigorously tested. Crews use tools like Optical Time Domain Reflectometers (OTDRs) to measure any signal loss and pinpoint faults. This step is non-negotiable—it ensures the network performs exactly to spec before it goes live.

- As-Built Documentation: Finally, the contractor creates detailed "as-built" maps and records. Think of these as the definitive blueprint of the finished network, showing precise splice locations, cable paths, and connection points. This documentation is absolutely invaluable for any future maintenance, troubleshooting, or upgrades.

How to Evaluate Your Next Construction Partner

Choosing a fiber optic construction partner is one of the most critical decisions you'll make. It directly impacts the future reliability and performance of your entire network. This isn't just about hiring a crew to dig trenches and pull cable; it's about finding a partner with the technical savvy, operational discipline, and project management chops to bring your vision to life without a hitch.

The right partner becomes an extension of your own team, bringing years of field-tested experience and proactive problem-solving to the table. A methodical evaluation process is your best defense against the budget overruns, painful schedule delays, and nagging network issues that can plague a poorly executed build. You need a solid framework for vetting potential fiber optic construction companies that goes far beyond a simple price sheet.

Assessing Technical Expertise and Experience

First things first: you have to dig into their proven technical capabilities. A company’s resume should align perfectly with the specifics of your project, from the network architecture you’re deploying to the unique physical environment you’re building in.

Start by grilling them on their direct experience with your chosen technology. Are you building a GPON network for a sprawling residential FTTH rollout? Or is it a high-density XGS-PON system for a congested urban core? A partner’s deep familiarity with these architectures is non-negotiable.

Beyond the tech, look at the diversity of their project portfolio. A contractor who has only ever worked in flat, suburban greenfield developments will likely be unprepared for the complexities of a historic downtown, where every street corner hides a new utility conflict.

Get specific with your questions in these key areas:

- Network Architecture: Probe their hands-on experience with technologies like GPON, XGS-PON, or point-to-point Ethernet.

- Environmental Diversity: Ask for project examples in environments similar to yours—be it dense urban, sprawling suburban, or rugged rural terrain.

- Construction Methods: Confirm their proficiency in both aerial and underground construction, including specialized techniques like directional boring or microtrenching that your project might demand.

Certifications and Safety Records Are Non-Negotiable

A truly professional contractor's commitment to quality and safety shines through in their certifications and documented safety programs. These aren't just pieces of paper to hang on a wall; they are objective proof of a company's dedication to industry best practices and, most importantly, to the well-being of their crews and the public.

Industry-recognized certifications from respected organizations like the Fiber Optic Association (FOA) or BICSI establish a baseline of technical competence. Insist on seeing the credentials for the specific technicians and project managers who would be assigned to your build. This ensures the people actually doing the work have been properly trained and tested.

A company’s safety record is the clearest indicator of its operational discipline. A low Experience Modification Rate (EMR) and clean OSHA logs show a proactive, well-managed organization that prioritizes risk mitigation—a trait that translates directly to project success.

It's also worth looking at how a potential partner embraces modern tools. For example, their approach to drone use in construction can reveal a lot about their commitment to efficiency and precision. This kind of forward-thinking adoption often correlates with more accurate surveying, better progress tracking, and improved safety oversight on the job site.

Evaluating Project Management and Communication

Here’s where many projects go completely off the rails. Even the most technically gifted crew will stumble without strong project management and crystal-clear communication. Your evaluation must scrutinize how a potential partner manages timelines, budgets, and the inevitable curveballs that pop up in the field.

A mature project management process is built on transparency and structure. The company should be able to walk you through its communication protocols without hesitation, from daily progress reports to formal change order procedures. This rigid structure is what keeps a complex build on track and ensures every stakeholder is on the same page.

Don't be shy—ask direct questions about their process:

- Reporting: What’s your standard procedure for daily, weekly, and monthly progress reporting? Can we see an example?

- Issue Resolution: How do you document and tackle unforeseen field issues, like hitting unmarked utilities or running into permitting roadblocks?

- Change Orders: What is your formal process for managing change orders to ensure budget and schedule impacts are spelled out clearly before work proceeds?

- Client Collaboration: What tools or platforms do you use to give us real-time visibility into project status?

A partner who gives confident, detailed answers is one who values collaboration and transparency. They get that building a network is a partnership, and keeping you in the loop is every bit as important as the physical construction itself. This collaborative spirit is the foundation of any successful, long-term relationship.

Key Evaluation Criteria for Fiber Optic Construction Partners

Choosing the right partner requires a systematic approach. This checklist can help you systematically compare and score potential fiber construction companies across the capabilities that matter most for a successful deployment.

| Evaluation Category | Key Performance Indicators (KPIs) | Why It Matters |

|---|---|---|

| Technical Expertise | Experience with specific architectures (GPON, XGS-PON), construction methods (boring, aerial), and diverse environments (urban, rural). | Ensures the contractor has the practical skills to handle the unique technical and geographical challenges of your specific project. |

| Certifications & Safety | FOA/BICSI certifications, low Experience Modification Rate (EMR), clean OSHA 300 logs, and a documented safety program. | Verifies a commitment to industry standards, quality work, and operational discipline, which reduces project risk and liability. |

| Project Management | Clear communication protocols, established change order processes, use of project management software, and regular reporting cadence. | Indicates an organized, transparent partner who can keep the project on schedule and on budget while managing unforeseen issues effectively. |

| Financial Stability | Positive credit history, proof of sufficient insurance and bonding capacity, and transparent financial statements. | Confirms the company has the financial resources to see a large-scale project through to completion without interruptions. |

| Client References | Verifiable references from past projects of similar scope and complexity, with a focus on communication and problem-solving. | Provides real-world proof of their performance, reliability, and ability to maintain a positive, collaborative client relationship. |

By using this table as a scorecard, you can move beyond gut feelings and make an objective, data-driven decision. The time invested in this thorough vetting process pays for itself by preventing costly mistakes and ensuring your network is built right the first time.

Real-World Project Scopes Across Different Industries

It’s one thing to talk about the services fiber optic construction companies offer in the abstract. It’s another to see how those skills translate into real-world projects.

The truth is, the needs of a rural broadband initiative are worlds apart from those of a hyperscale data center. A truly experienced partner knows this instinctively and has the flexibility and deep expertise to pivot between vastly different project goals.

Let's walk through a few common scenarios to show you how these construction partnerships look in practice. This will give you a feel for the unique challenges and creative solutions that come with each type of build.

Telecom Carriers: A Greenfield FTTH Build

Picture a growing suburban community where a major telecom carrier wants to deploy a brand new Fiber-to-the-Home (FTTH) network. This is a classic "greenfield" project—building everything from scratch where no fiber infrastructure existed before.

The primary mission here is massive scale: pass thousands of potential homes and businesses with high-capacity fiber. For a fiber construction partner, the scope is a symphony of logistics.

- Extensive Route Design: The first step is deep in the planning phase. Engineering teams meticulously map the entire community, figuring out the most efficient paths for the mainline "feeder" fiber and the smaller "distribution" cables that spiderweb down individual streets. This includes using modern tools and even drone use in construction for initial surveys.

- High-Volume Make-Ready: This project will inevitably involve a huge amount of make-ready work. That means constant coordination with power and telephone utilities to get hundreds, or even thousands, of poles ready for new aerial cable.

- High-Density Splicing: At each neighborhood cabinet, technicians have to perform incredibly precise, high-density splicing. They’re connecting large feeder cables to dozens of smaller distribution fibers. It’s a job that demands extreme organization to ensure every single home gets a clean, powerful signal.

A project like this is a masterclass in coordination. The contractor's ability to manage multiple crews, navigate complex permitting, and maintain a rock-solid supply chain is what makes or breaks the timeline for connecting new subscribers.

Data Center Operators: A Diverse-Path Campus Buildout

Now, let's shift gears to a data center operator building a new hyperscale campus. The priorities here are completely different. It’s not about reaching individual homes; it’s about creating bulletproof, high-density connections between massive buildings and out to the global internet. Redundancy and near-zero latency are everything.

For a data center, the construction partner's scope is all about security, reliability, and raw performance.

- Diverse-Path Redundancy: The non-negotiable task is building at least two physically separate—or "diverse"—fiber routes into each facility. If a backhoe cuts one path, the other keeps the entire data center online without a blip. This often requires complex https://southerntierresources.com/heavy-civil-construction/ work to create secure, dedicated underground pathways.

- High-Count, High-Density Cabling: Forget small subscriber cables. Here, the contractor is installing monster fiber trunks, often with 864 fibers or more in a single cable. Inside the facility, they terminate these with high-density connectors to handle staggering amounts of data.

- Rigorous Testing and Documentation: Every single strand of glass is meticulously tested for performance metrics like insertion loss and reflection. The "as-built" documentation that’s handed over isn't just a record; it’s the operational bible for the facility’s network team.

The demands on fiber construction are only getting more intense. We've moved beyond simple FTTH networks into a world of dense 5G, edge computing, and massive data center ecosystems. The global market for fiber optic connectors reflects this, projected to more than double from USD 6.42 billion in 2025 to USD 13.86 billion by 2034. As connection density skyrockets, contractors are no longer just laying cable—they are essential integrators of incredibly complex systems.

Municipalities: A Public Broadband Initiative

Finally, let's look at a city or county aiming to bridge the digital divide. Their goal is to connect key "community anchor institutions"—think schools, libraries, fire stations, and government offices. This kind of project is a hybrid, borrowing elements from carrier and enterprise builds but with its own set of public-facing pressures.

The success of a municipal project is often measured not just by technical performance but also by public perception and fiscal responsibility. The construction partner must be an excellent communicator and a careful steward of taxpayer funds.

The scope for a municipal build often includes these unique elements:

- Multi-Stakeholder Coordination: The contractor has to be a diplomat, working closely with various city departments, community groups, and public utility commissions. Strong communication and public relations skills are just as important as technical ability.

- Phased Deployment: Public budgets are often allocated in stages, meaning a project might unfold over several years. The construction partner has to be skilled at long-range planning and breaking the build into logical, functional phases.

- Connecting Diverse Facilities: This work involves linking a wide variety of buildings, and each one has its own internal wiring quirks and challenges. It requires a versatile team that is equally comfortable with large-scale outside plant (OSP) work and nuanced inside plant (ISP) installations.

The Essential RFP and Contractor Questions Checklist

When you’re choosing a fiber optic construction company, the lowest bid is rarely the best value. To find a true partner, you need to ask tough, specific questions that go far beyond the price tag. Your Request for Proposal (RFP) is the single most important tool for this job.

Think of your RFP less like a shopping list and more like a detailed job interview. You aren't just buying a service; you're hiring a team to build one of your most critical assets. The questions you ask should be designed to peel back the layers and reveal a company’s operational discipline, technical depth, and overall stability.

This checklist is your framework for a thorough evaluation. It’s designed to help you identify a partner who is genuinely invested in your project's success.

Safety and Compliance

A contractor's attitude toward safety tells you everything you need to know about their professionalism and how they manage risk. A team that cuts corners on safety will inevitably cut corners elsewhere. Don't just ask if they "have a safety program"—dig into the specifics with questions that demand real proof.

When building out your RFP, be sure to inquire about their track record with specific regulations, including their adherence to critical electrical safety standards like NFPA 70E.

- Can you provide your Experience Modification Rate (EMR) for the past three years? An EMR below 1.0 is a strong indicator of a better-than-average safety record. It’s a number that doesn’t lie.

- May we review your OSHA 300 logs? These logs offer a transparent, documented history of any workplace injuries or illnesses.

- How do you conduct job site safety analysis (JSA) and daily "tailgate" meetings? You want to see a proactive, daily commitment to identifying and mitigating risks before the work even starts.

- What percentage of your field staff holds OSHA 10 or OSHA 30 certifications? This shows a direct investment in formal, structured safety training for the entire crew.

Technical Capability and Experience

This is where the rubber meets the road. You need to confirm the contractor has the actual hands-on skills required for your project. Vague claims of "experience" are meaningless. Your questions should force them to provide concrete evidence of their expertise.

Don’t just ask what they can do; ask what they have done. Requesting case studies from projects with similar scope, complexity, and geographic challenges is one of the most effective ways to validate their capabilities.

- Describe your company's experience with high-count ribbon splicing and mass fusion splicing. This is absolutely critical for any high-density network build.

- What types of OTDR and power meter testing equipment do you own and use? A serious player will own their own modern, calibrated equipment, not rent it on a whim.

- Provide examples of projects where you performed extensive make-ready engineering and coordination with utility pole owners. This reveals their real-world experience navigating the tricky relationships with third parties.

- Detail your quality assurance process for splicing, testing, and documentation. Look for a systematic, repeatable process—not just an informal checklist.

Project Management and Financial Stability

Even the most skilled crew will fail without strong project management and a solid financial footing. These questions are designed to assess their ability to manage a complex timeline, communicate clearly, and weather the financial ups and downs of a large-scale project.

- What project management software do you use for scheduling, resource allocation, and client reporting? This is a window into their commitment to transparent, structured management.

- What is your formal process for managing change orders? A clear, documented process is your best defense against scope creep and surprise budget overruns.

- Can you provide proof of your bonding capacity for a project of this size? This is non-negotiable. It confirms they have the financial backing to guarantee the project gets completed, no matter what.

- Please provide three client references for projects of a similar scale completed in the last 24 months. There's no substitute for due diligence. Actually calling past clients is the ultimate gut check.

Building a Partnership for Long-Term Network Success

Choosing a fiber optic construction company isn’t just about hiring a vendor—it’s about starting a long-term partnership. The decisions you make today will directly impact your network's performance and reliability for years, so it's critical to build this relationship on a foundation of proven skill and trust.

This decision really boils down to four key pillars. You need a partner with deep technical mastery—the kind that only comes from years of hands-on experience with complex construction and precision splicing. You also need an unshakeable commitment to safety, which is often the clearest indicator of a company's overall discipline. The third pillar is transparent project management, ensuring you’re never in the dark about progress. And finally, you need clear, consistent communication, which is the glue that holds the entire partnership together.

Your Network's Long-Term Steward

Think of your network as a digital highway. The right partner doesn’t just lay the asphalt and disappear. They’re the expert engineers and maintenance crews who keep that highway running smoothly for its entire lifespan, becoming invested in your success and ready to help you navigate whatever comes next.

Your goal is to find a team that sees beyond the initial build. The ideal partner is prepared to support future upgrades, troubleshoot issues, and help you adapt as technology and demand evolve, ensuring your investment remains valuable for decades.

This forward-thinking mindset is what separates a simple contractor from a true infrastructure partner. A company that offers comprehensive, turnkey network solutions is built from the ground up to provide this level of end-to-end support, from the first blueprint to long-term maintenance cycles.

Ultimately, you’re choosing a steward for one of your most critical assets. When you prioritize technical depth, safety, transparency, and a truly collaborative spirit, you can confidently select a partner who will not only build your network right but help it thrive for the long haul.

Common Questions About Fiber Construction

Even with a solid plan, a few questions always pop up during a fiber deployment. Getting a handle on the key variables that drive costs and timelines is the best way to set realistic expectations for your team, your stakeholders, and the fiber optic construction companies you partner with.

Let's break down some of the most frequent questions we hear.

What Really Drives Fiber Construction Costs?

It's easy to assume the biggest expense is the fiber optic cable itself, but that’s rarely the case. The materials are often just a small fraction of the total budget. The real costs are buried in the labor, logistics, and legwork required to physically place that cable where it needs to go.

You can boil down the primary cost drivers into four main categories:

- Labor: This is almost always the biggest line item. It covers everyone from the crew running a directional drill to the highly specialized technician splicing the glass fibers together.

- Materials: This bucket includes the fiber cable, of course, but also the conduit to protect it, connectors, splice enclosures, and all the other hardware needed to build the network.

- Permitting Fees: The administrative side of construction can be surprisingly expensive. Securing right-of-way access and construction permits from local governments, DOTs, and utilities adds up.

- Make-Ready Engineering: Before you can hang a new cable on a utility pole, that pole has to be ready for it. This prep work, which involves analyzing pole load and moving existing attachments, is a critical and often costly step.

How Long Does a Fiber Project Actually Take?

This is the classic "it depends" answer, but for good reason. A short point-to-point connection between two buildings might be done in a few weeks. A city-wide Fiber-to-the-Home (FTTH) network could easily take a few years.

What's interesting is that the biggest delays often have nothing to do with the physical construction work.

The real schedule-killers are the administrative hurdles you have to clear before the first shovel ever hits the ground. Getting ahead of these is the secret to keeping a project on track.

Permitting approvals, right-of-way negotiations, and pole attachment agreements with utility companies can all stretch a timeline. And don't forget Mother Nature—bad weather can bring both aerial and underground work to a complete standstill for days or even weeks.

What’s the Difference Between OSP and ISP Construction?

These acronyms get thrown around a lot, but the distinction is pretty simple. Outside Plant (OSP) and Inside Plant (ISP) just refer to where the work happens, but each requires a completely different set of skills, tools, and expertise.

- Outside Plant (OSP): Think of this as all the heavy lifting that happens outdoors. It’s the civil construction work—directional boring under a road, trenching through a field, or hanging new aerial cable on a line of utility poles.

- Inside Plant (ISP): This is everything that takes place inside a building. It could be running structured cabling through a data center, connecting fiber to individual apartments in a high-rise, or setting up the equipment in an office's telecom closet.

A truly end-to-end network build demands a partner who is fluent in both. This ensures a clean handoff from the outdoor network backbone to the final connection point inside your building, avoiding the communication gaps and technical hiccups that can happen when two separate teams are involved.

At Southern Tier Resources, we provide the end-to-end engineering, construction, and maintenance expertise to build reliable, high-performance fiber networks. Learn more about our turnkey solutions at southerntierresources.com.