If you're looking for a simple, one-size-fits-all price for fiber optic installation, you won't find one. The truth is, the cost to build a fiber network can swing dramatically, generally falling between $40,000 to over $80,000 per route mile.

That massive range comes down to one key factor: where and how you're building. Stringing cable on existing utility poles is always going to be the most budget-friendly route. But if you need to bury that cable, especially under the crowded streets of a city, the complexity—and the cost—skyrockets.

What Is the Real Cost of Fiber Optic Installation

Trying to nail down the true cost of a fiber project is a lot like pricing out a custom-built house. The final number depends entirely on the blueprint, the materials you choose, and the challenges of the land you're building on. There's simply no sticker price. Instead, your final budget is a blend of dozens of variables, from labor and materials to permits and heavy civil work.

For any organization—whether you’re an ISP, a municipality, or a data center operator—getting a handle on these variables is the first and most critical step in planning a realistic budget. The single biggest cost driver is the environment itself. A dense urban core, a quiet suburb, and a sprawling rural landscape each present a completely unique set of challenges and expenses.

Comparing Costs Across Different Environments

To get a realistic feel for budgeting, it’s helpful to see how these numbers shift from one environment to the next. Looking at industry data, a clear pattern emerges: the more complex and populated the area, the higher the price tag.

We've seen costs climb significantly in recent years. Today, building out a Fiber-to-the-Home (FTTH) network with underground construction in a city averages between $60,000 and $80,000 per route mile. On the other hand, aerial projects that "overlash" new fiber onto existing poles are far more economical, typically running between $40,000 and $60,000 per route mile.

This upward trend isn't slowing down. In fact, a recent survey showed that 88% of industry professionals expect costs to keep rising due to persistent labor shortages and material price hikes. You can dig deeper into these trends in this report on the cost of fiber optic cable.

To give you a clearer picture, here’s a quick breakdown of what you can expect in different settings.

At-a-Glance Fiber Installation Cost Estimates by Environment

This table provides a high-level summary of estimated costs for different fiber optic deployment scenarios, helping stakeholders quickly gauge budget requirements.

| Deployment Type | Typical Cost Per Route Mile | Typical Cost Per Household Passed |

|---|---|---|

| Dense Urban | $60,000 – $100,000+ | $700 – $1,500 |

| Suburban | $40,000 – $70,000 | $1,200 – $2,500 |

| Rural | $50,000 – $90,000 | $3,000 – $6,000+ |

These figures underscore just how much the environment dictates the investment required for a successful fiber build.

The Value of an Experienced Partner

Navigating all these financial variables requires a team with deep, hands-on expertise in engineering, construction, and project management. A small miscalculation in permitting fees or an unexpected rock ledge discovered during trenching can easily lead to major budget overruns and painful project delays.

This is exactly why choosing an experienced turnkey partner is so crucial. When a single, accountable team manages every phase—from initial design and route planning to final testing and closeout documentation—you gain control. This integrated approach ensures all cost drivers are identified and managed from the start, keeping your project on time and on budget.

What Really Drives the Cost of a Fiber Project?

Think of budgeting for a fiber network like building a custom home. You don't just get a single, flat price. Instead, the final cost is the sum of every single component—every material, every hour of skilled work, and all the foundational groundwork needed to turn the blueprint into reality. Getting a handle on these individual cost drivers is the only way to build a realistic budget and sidestep major financial surprises later on.

A home builder has to track the cost of lumber, concrete, and wiring. In the same way, a fiber project manager has to account for every foot of cable, conduit, and every single connector. While these material costs seem small individually, they add up fast over a multi-mile network. But here’s the thing most people miss: the biggest line items often aren't what you're installing, but where and how. The actual physical work of getting that fiber in the ground or on a pole is where the majority of your budget is going to go.

This is exactly why a detailed, unit-based pricing model is so crucial. It gives you a transparent, line-by-line view, so you know precisely what you're paying for.

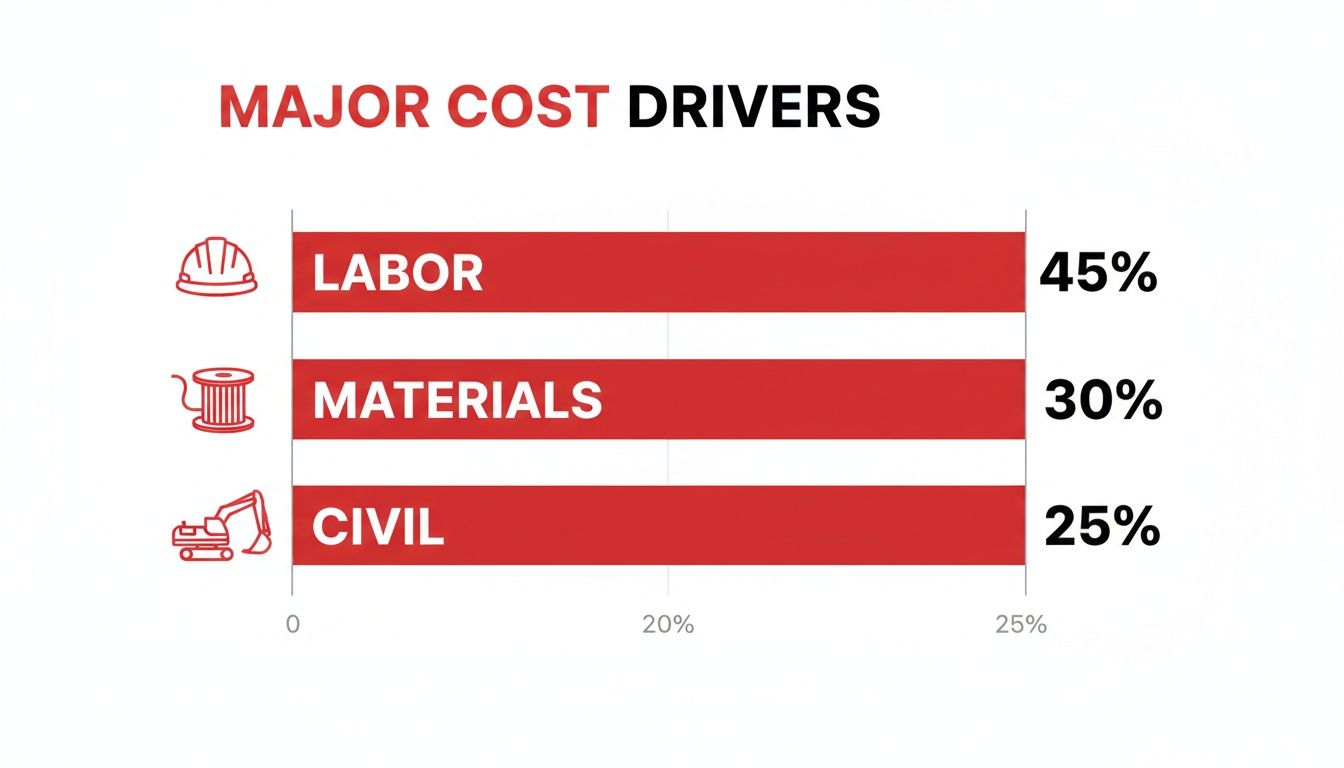

The Big Three: Materials, Labor, and Civil Work

When you look at your capital expenditure (CAPEX), the vast majority of it will fall into three main buckets. Each is a critical piece of the puzzle, and their costs can swing wildly depending on the project's location and specific challenges.

Material Costs: This is the "lumber and nails" of your network. We're talking about the fiber optic cable itself, the protective conduit it's housed in, splice closures, connectors, and all the mounting hardware for an aerial build. Material prices do fluctuate with the market, but they tend to be a fairly predictable slice of the budget pie.

Labor Expenses: These are your skilled tradespeople—the "carpenters" and "electricians" of the fiber world. This category covers the wages for highly trained splicing technicians, linemen who work on the poles, heavy equipment operators, and the project managers keeping everything on track. Local wage rates, how complex the job is, and the need for specialized skills all play a big role here.

Civil Works: This is the heavy lifting, the literal "foundation" of your network. It's all the construction required to clear a path for the fiber, especially for underground projects. Civil work can easily become the single most expensive part of a build, often accounting for over 50% of the total fiber optic installation cost.

For any buried fiber project, a huge part of that civil cost comes from the work done by utility trenching contractors. This isn't just digging a ditch; it involves trenching, directional boring to get under roads and rivers, and then putting the landscape back exactly as it was.

Don't Forget the "Soft Costs"

Beyond the hard hats and heavy machinery, a successful project depends on a mountain of planning, paperwork, and administrative oversight. These "soft costs" might be less tangible, but they are absolutely critical to your budget.

A classic mistake we see is when project owners focus entirely on the construction costs. They forget to budget for the significant time and money spent on planning, design, and navigating the regulatory maze. These upfront steps actually dictate how efficient and cost-effective the entire build will be.

These essential background tasks are what ensure your network gets built correctly, legally, and on schedule. Skimp on them, and you're asking for delays and costly fines.

Key Soft Costs to Build Into Your Budget

Engineering and Design: This is your network's architectural blueprint. It’s not just a line on a map; it involves meticulous route planning, detailed pole surveys for aerial runs, and creating the construction-ready schematics your crews will work from. Solid engineering is your first and best defense against budget overruns.

Permitting and Right-of-Way (ROW): You can't touch a shovel to dirt without permission. This means securing permits from cities, counties, and departments of transportation. It also involves the often-tricky process of negotiating access rights with private property owners. The fees and legal legwork here can be surprisingly time-consuming and expensive.

By breaking down your project into these core drivers—both the hard and soft costs—you get a much more accurate picture of your total investment. This level of detail makes for better forecasting and highlights the incredible value of a true turnkey partner who can manage all these moving parts from day one.

Putting It All Together: Cost Scenarios for Common Fiber Builds

Theory is one thing, but seeing how the numbers play out in the real world is what really matters for budgeting. The final price tag for a fiber optic installation is almost entirely dictated by the environment. Connecting a packed downtown, a quiet suburb, or a sprawling rural area? Each comes with its own set of challenges that directly hit the bottom line.

To get a clearer picture, let's walk through a few common scenarios. These examples show how the core cost drivers—materials, labor, and civil work—stack up differently based on the project’s specific demands. This gives network operators and IT teams a practical framework for seeing how expert planning can make a budget work in any environment.

This chart quickly shows where the money typically goes in a fiber project. It’s a great visual for understanding where the biggest investments are made.

As you can see, labor and the civil work needed to clear the path are consistently the biggest line items, often dwarfing the cost of the fiber cable itself.

Scenario 1: The Urban Aerial Overlash

In a dense city core, digging up streets to bury new cable is often a non-starter—it’s just too expensive and disruptive. The smart play is usually an aerial "overlash," which involves attaching new fiber to existing utility poles. This move sidesteps a huge chunk of the civil work costs.

- Scope: A 5-mile network build connecting multiple commercial buildings in a busy downtown.

- Key Cost Drivers: The budget here is driven by make-ready engineering (getting poles ready for new attachments), pole attachment fees, and the specialized labor required to work safely in high-traffic urban areas.

- Estimated Cost: You could be looking at $40,000 to $60,000 per route mile. The biggest wildcards are the condition of the existing poles and what the pole owners charge for access.

Scenario 2: The Suburban Underground Trench

Now, picture a classic suburban neighborhood where curb appeal is key and most utilities are already underground. The go-to method is trenching, where crews dig a shallow channel to lay conduit and pull the fiber through.

This is a much more hands-on process than an aerial build. It demands heavy machinery, meticulous coordination to avoid hitting existing utility lines, and a fair amount of restoration work to put lawns, sidewalks, and driveways back together.

For residential projects, the "cost-per-home-passed" is the number everyone watches. It's the investment needed to make service available to a potential customer, even before they sign up.

Globally, the average cost to pass a home with fiber hovers between $1,000 and $1,250. But this number can swing wildly based on the environment. A tightly packed city might come in at $700 to $1,500 per home, while a spread-out rural area can easily push that to $3,000 to $6,000.

To illustrate how these costs break down in a suburban environment, let's look at a sample project. The table below outlines the budget allocation for a typical 10-mile Fiber-to-the-Home (FTTH) build, showing how different components contribute to the total expense.

Sample Cost Breakdown for a 10-Mile Suburban FTTH Project

| Cost Component | Estimated Percentage of Total Budget | Notes and Key Considerations |

|---|---|---|

| Civil Work (Trenching & Restoration) | 40% | The largest single expense. Includes machinery, fuel, and significant labor for digging and repairing surfaces like asphalt and lawns. |

| Labor (Splicing, Testing, PM) | 25% | Covers skilled technicians for fusion splicing, OTDR testing, and overall project management to keep things on schedule. |

| Materials (Cable, Conduit, Handholes) | 15% | Includes the fiber optic cable itself, protective conduit, splice closures, and underground vaults (handholes). |

| Make-Ready & Permitting | 10% | Costs for engineering studies, municipal permits, traffic control plans, and fees for crossing roads or existing utility lines. |

| Equipment & Electronics (OLTs/ONTs) | 5% | Covers the active electronics in the central office (OLT) and at the customer premises (ONT). |

| Documentation & As-Builts | 3% | The critical final step of creating detailed maps of the finished network for future maintenance and troubleshooting. |

| Contingency Fund | 2% | A necessary buffer for unexpected issues, like hitting underground rock or discovering unmapped utilities. |

This breakdown makes it clear that the physical work of placing the fiber underground is, by far, the most significant investment in a suburban build.

Scenario 3: The Rural FTTH Build

Connecting rural communities is a whole different ballgame. The distances are vast and the homes are few and far between, which completely changes the economic equation. These projects usually require a mix of aerial and buried construction to handle the varied terrain.

- Scope: A 20-mile FTTH network designed to bring high-speed internet to 500 homes in an area that’s never had it.

- Key Cost Drivers: The sheer distance cranks up both material and labor costs. You’ll often need directional boring to get under rivers or major roads, which adds another significant expense.

- Estimated Cost: Rural builds frequently have the highest per-mile costs, sometimes landing in the $50,000 to $90,000 per route mile range, all depending on the terrain and the mix of construction methods.

Scenario 4: The Data Center Interconnect

Finally, let’s talk about a high-stakes data center interconnect. Here, the priorities are rock-solid redundancy and ultra-low latency. The mission is to build a bulletproof, high-capacity link between two mission-critical facilities. For a deeper dive, check out our guide on designing a high-speed data center connection.

These projects almost always demand fully redundant, buried pathways. That means digging two completely separate routes to ensure a single backhoe accident can’t take down the entire connection. The depth of the trenches and the quality of the conduit are absolutely non-negotiable, which adds to the cost. With these builds, the focus is squarely on 100% reliability, a goal that easily justifies the higher upfront investment.

Budgeting for the Full Network Lifecycle

The initial price tag for a fiber build-out is a serious capital expense, but it’s really just the first chapter of the network’s financial story. To get a true grasp of the fiber optic installation cost, you have to look beyond the upfront investment and consider the Total Cost of Ownership (TCO) over the network's entire life.

This means shifting your focus from the one-time capital expense (CAPEX) of construction to the ongoing operational expenses (OPEX) needed to keep the lights on.

From CAPEX to OPEX

Think of OPEX as the routine care for a high-performance machine; it's essential for longevity and reliability. Once your network goes live, your budget must account for these recurring activities that ensure its health and performance.

- Network Monitoring: This is your 24/7 watchtower, keeping an eye on performance to catch issues before they ever reach your customers.

- Routine Maintenance: Proactive work, like inspecting splice enclosures or managing vegetation near aerial cables, is what prevents expensive, middle-of-the-night emergency calls.

- Emergency Repairs: Let's be realistic. Even the most robust networks can get hit by storms or backhoes. You absolutely have to budget for "truck rolls" and emergency splicing.

- Future Upgrades: The glass itself is incredibly future-proof, but the electronics on either end of it will eventually need an upgrade to deliver the next generation of speed and services.

The immense global demand for this technology is a huge factor in these cost dynamics. The fiber optic cable market, valued at $84.15 billion in 2025, is expected to surge to $115.79 billion by 2030, largely thanks to 5G rollouts and the explosive growth of data centers. Here in North America, the market is projected to hit a $3.47 billion share in 2025—a clear sign of the massive investments pouring into this infrastructure. You can dig into more detailed projections for the fiber optical cable market to see how these trends are shaping project budgets.

The Long-Term Value of a Quality Build

This is where fiber truly pulls away from the pack. While that initial CAPEX can be substantial, the long-term value proposition is undeniable. Fiber optic cables have a remarkable lifespan, often performing reliably for 20 to 30 years, or even longer.

A well-engineered and properly installed fiber network is one of the most durable infrastructure assets you can build. It requires significantly less maintenance than legacy copper or coaxial networks, which are prone to corrosion and signal degradation.

This durability pays direct dividends in the form of lower OPEX down the road. A high-quality initial build, backed by meticulous testing and documentation, drastically cuts down on future troubleshooting and repairs.

For instance, starting with thorough as-built surveys and documentation makes future maintenance calls faster and far more efficient, directly slashing your operational costs for decades to come.

Ultimately, investing a bit more upfront in quality engineering and construction pays for itself many times over. It minimizes long-term operational headaches and delivers a much stronger, more predictable return on your investment, turning a one-time cost into a generational asset.

How to Choose the Right Installation Partner

Here’s the thing about fiber projects: the single biggest factor influencing your fiber optic installation cost isn't the cable or the route. It's the people you hire to build it. A great partner becomes an extension of your own team, navigating around expensive problems before they even happen. The wrong one can send your budget spiraling, blow past deadlines, and leave you with a network that’s a headache for years to come.

Finding the right installation partner means finding a team that can juggle every complex piece of the puzzle, from the first survey to the final test. This is why a true turnkey provider is so valuable. They offer a single point of accountability, which means no finger-pointing between different subcontractors when things get tough. When one team owns the entire outcome, you get the transparency and control you need to protect your investment.

Vetting Your Potential Partners

It’s tempting to jump at the lowest bid, but that’s often a trap. A cheap quote can hide inexperience or a tendency to cut corners, both of which will cost you dearly down the road. To really understand who you’re dealing with, you need a structured way to vet potential installers. This helps you compare apples to apples and pick a partner who’s in it for the long haul.

Your evaluation needs to be tough, focusing on real-world experience and what they can actually do in-house. A partner's ability to handle everything from engineering to construction without outsourcing every step is a huge green flag. It shows they have the resources and expertise to run the project smoothly and efficiently.

The real measure of a partner isn't just their ability to put fiber in the ground. It's their commitment to meticulous planning, transparent communication, and delivering a network that is documented, tested, and built to perform for decades.

A Non-Negotiable Checklist for Partner Selection

When you start talking to potential partners, think of it as an audit. Don’t just take their word for it—ask for proof. Here are the essentials you need to dig into:

- Proven Experience: Have they actually built projects like yours before? Ask for specific case studies and references for builds of a similar scope, scale, and environment, whether it's urban aerial, suburban trenching, or rural FTTH.

- Verifiable Safety Record: What is their Experience Modification Rate (EMR) and overall safety culture like? A solid safety record is non-negotiable. It speaks volumes about a company’s discipline and professionalism.

- In-House Expertise: Do they have their own teams for engineering, permitting, construction, and splicing? A heavy reliance on subcontractors is a recipe for communication breakdowns and accountability problems.

- Comprehensive Testing Protocols: How will they prove the network works? Insist on seeing their testing procedures. You want end-to-end certification using OTDRs and power meters to confirm every strand meets spec before you sign off on the project.

- As-Built Documentation: Will they provide detailed, geo-referenced as-built maps when they’re finished? This documentation is absolutely critical for future maintenance, repairs, and expansion. Operating a network without it is like flying blind.

Focusing on these core competencies will help you cut through the sales pitches and find a single, accountable partner. You’ll be choosing a team that will not only protect your investment but also build a high-quality network designed to deliver value for decades.

Answering Your Top Questions About Fiber Installation Costs

Even with a solid plan in hand, you're bound to have specific questions about the real-world costs of a fiber installation. Let's tackle some of the most common ones we hear from clients to give you a clearer picture of what to expect for your budget.

Why Is Underground Fiber Installation So Expensive?

The short answer? It's all about the civil work. Putting fiber underground isn't just about burying a cable; it involves a whole lot of heavy lifting.

You’re looking at major earth-moving activities like trenching (digging a long, open channel) or directional boring (drilling a precise path under roads, driveways, or sensitive landscapes). This work demands specialized machinery, a skilled crew, and often, a mountain of paperwork for permits. Then, you have the added cost of installing protective conduit and restoring everything—from lawns to pavement—back to its original state.

Compare that to an aerial installation, which piggybacks on existing utility poles. While not free, it sidesteps most of the heavy civil work. The big expenses shift to pole attachment fees and getting the poles ready, but it's almost always a faster and more budget-friendly route when the infrastructure is already there.

What Are Make-Ready Costs and Why Are They Important?

"Make-ready" is the industry term for all the prep work needed to get existing utility poles ready for your new fiber cable. Think of it like preparing a wall before you paint it. You can't just string up a new line wherever you want.

This process often involves shuffling existing cables from the power company or other providers to make room. Sometimes, older poles need to be replaced entirely because they can't handle the new weight or meet modern safety codes. It's a complex dance of engineering, coordination, and physical labor.

Don't underestimate this step. Make-ready costs can easily eat up 20-30% of an entire aerial construction budget. A good partner will insist on doing detailed pole surveys early on to give you an accurate estimate. Skipping this diligence is one of the quickest ways to blow your budget.

Make-ready isn't just another line item; it's a critical phase that can make or break the timeline and budget of an aerial build. Underestimating it is one of the most common—and costly—mistakes we see.

How Much Does the Final Drop Add to the Cost?

The "fiber drop" is that last crucial link—the connection from the main fiber line running down the street to an actual home or business. While you might budget for the core network based on cost-per-mile or per-home-passed (which can run from $700 in dense urban areas to over $3,000 in rural ones), the drop is a separate, additional expense.

A single fiber drop typically costs between $250 and $1,000 per location. The final price tag depends on a few things: how far the building is from the street, whether the drop is buried or hung from a pole, and how complex it is to get the cable inside. This cost covers the final piece of cable, the labor for splicing and connection, and the testing to light up the service.

How Do Different Pricing Models Affect My Budget?

Choosing the right pricing model is crucial for controlling your budget and managing financial risk. Each approach comes with its own set of pros and cons.

- Per-Foot Model: This is simple and easy to track. You pay for exactly what you build. The downside is that you carry all the risk—if unforeseen obstacles pop up, the final bill can climb quickly.

- Per-Home-Passed Model: This model ties the cost directly to your potential revenue base, which is perfect for ISPs building out new residential networks. It aligns your investment with your business goals.

- Turnkey (Fixed-Price) Model: This offers the highest level of budget security. The contractor gives you a single, all-in price and assumes the risk of any cost overruns. It's a favorite for public-funded projects or for organizations that need absolute cost predictability.

The best fit really depends on how predictable your project is, its overall scale, and how much financial risk your organization is comfortable taking on.

Navigating these complexities is what we do best. At Southern Tier Resources, we provide the end-to-end expertise to manage every cost driver and deliver your network on time and within budget. Contact us today to discuss your project.