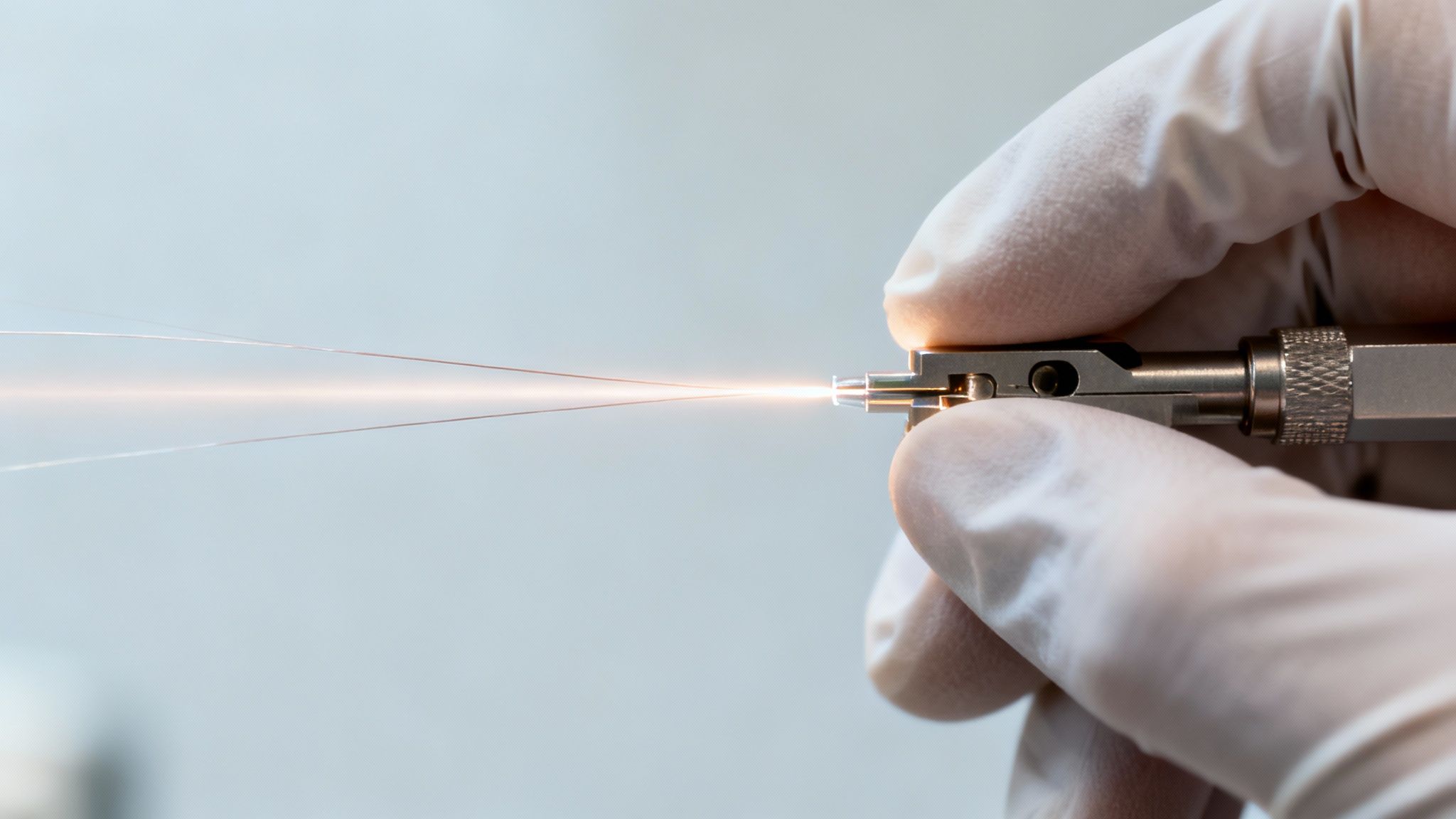

At its core, fiber splicing is the highly specialized craft of joining two fiber optic cables end-to-end. It's a meticulous process designed to ensure light signals can leap from one fiber to the next with minimal loss, creating a single, unbroken pathway for data to fly at nearly the speed of light.

The Hidden Backbone of Modern Networks

Behind every cloud transaction, video call, or stream is an invisible network that relies on an uninterrupted flow of data. Think of it like a massive water pipeline. For water to move efficiently from the reservoir to your tap, every joint must be perfectly sealed—no leaks, no blockages. Fiber splicing services provide that same flawless connection for our digital world.

Technicians use specialized equipment to align and permanently join two glass fibers, each thinner than a human hair. This isn't like twisting together a couple of copper wires; it’s a delicate, high-tech procedure that requires real expertise to fuse glass cores together into one seamless connection.

Why Quality Splicing Is Essential

The quality of a splice directly dictates network speed and reliability. A poorly executed splice acts like a bottleneck, weakening the light signal, slowing down data, and even causing complete outages. On the other hand, a perfect splice is virtually as good as an unbroken strand of fiber. It’s what makes modern network infrastructure possible.

This work is critical across several key areas:

- 5G Networks: Building the massive data backhaul needed to support next-generation wireless speeds.

- Fiber to the Home (FTTH): Bringing high-speed internet directly into neighborhoods and homes.

- Data Center Connectivity: Linking servers and switches with the high-bandwidth, low-latency connections they demand.

Expert fiber splicing is the lifeblood for network expansion and performance, especially in mission-critical facilities like large-scale data centers.

A flawless splice is invisible to the data traveling through it. The goal of every technician is to create a connection so perfect that the network operates as if the splice isn't even there, guaranteeing maximum performance and uptime.

This meticulous work is more than just a technical task; it's a fundamental pillar of network integrity. As our hunger for data continues to grow, so does the demand for these precise connections. The market for optical fiber splices was projected to hit $769.1 million by 2025, driven by an estimated 200 million splice units being deployed every single year.

Fusion vs. Mechanical Splicing: Choosing the Right Method

When you need to join two fiber optic cables, the goal is always the same: create a connection so seamless that light passes through as if the cable was never cut. Think of it like welding two pipes together so perfectly that water flows without a single drop lost. In the world of fiber optics, we have two main ways to do this: fusion splicing and mechanical splicing.

While they both get the job done, they are worlds apart in how they work, the performance they deliver, and where you’d want to use them.

Fusion Splicing: The Gold Standard for Network Performance

Fusion splicing is the closest thing we have to perfection. It's less of a connection and more of a re-creation, using a high-precision machine to literally melt the glass ends of two fibers and fuse them into one continuous piece. The result is a bond that's incredibly strong and offers the lowest possible signal loss.

For any network where performance is the top priority, fusion splicing is the only real choice. The process itself is meticulous, demanding clean conditions and a skilled hand, but the payoff is a connection that's virtually identical to a brand-new, unbroken fiber. We're talking about an insertion loss of less than 0.1 decibels (dB) and almost no back reflection—the kind of quality essential for moving massive amounts of data over long distances.

You'll find fusion splicing is the go-to method for:

- Long-Haul & Metro Networks: When your signal is crossing cities or states, every tiny bit of loss adds up. Fusion splicing keeps that loss to an absolute minimum.

- Data Center Interconnects: In an environment where every nanosecond counts, you can't afford the signal degradation from lesser connection methods.

- Submarine Cables: Under the ocean, repairs are next to impossible, so the initial connection has to be permanent and flawless.

- FTTH Backbones: Building the core infrastructure that brings high-speed internet to thousands of homes requires rock-solid, high-performance connections.

Yes, the equipment for fusion splicing is a significant investment, and it takes a true professional to do it right. But for critical infrastructure, the incredible reliability and long-term stability make it the most cost-effective decision in the long run.

A high-quality fusion splice is an investment in future-proofing your network. By creating a connection with near-zero signal degradation, you ensure the infrastructure can support next-generation bandwidth demands without needing premature upgrades or repairs.

Mechanical Splicing: A Fast and Flexible Tool for Specific Jobs

So if fusion splicing is the best, why does mechanical splicing even exist? Because sometimes, speed and simplicity are more important than perfect performance.

Think of a mechanical splice as a high-tech, miniature clamp. It doesn't permanently fuse the fibers. Instead, it aligns the two ends with microscopic precision inside a small housing and uses a special index-matching gel to help the light bridge the tiny gap between them. It’s a clever and effective solution, but it’s not a true weld.

This method is a lifesaver in certain situations. Imagine a backhoe rips through a major fiber line, knocking a whole neighborhood offline. The top priority isn't creating a perfect, long-term splice; it's getting service back up now. A technician can perform a mechanical splice in just a few minutes, restoring the connection and getting people back online while a permanent fusion repair can be scheduled for later.

Mechanical splicing shines in scenarios like:

- Emergency Cable Restorations: Its speed is unmatched for minimizing downtime during an outage.

- Temporary Setups: Perfect for events, construction sites, or testing where a permanent link isn't needed yet.

- "Last Mile" Connections: In some Fiber-to-the-Home (FTTH) applications, the connection from the curb to the house doesn't face the same extreme performance demands as the core network.

The trade-off, of course, is performance. A mechanical splice typically introduces much higher signal loss (from 0.3 dB to 0.75 dB) and significantly more back reflection. That's perfectly fine for a short, temporary fix, but it's a non-starter for a high-performance network backbone. To get a better sense of the technology involved, you can learn more about fusion splicing tools and techniques and see how the equipment itself dictates the outcome.

Fusion Splicing vs Mechanical Splicing At a Glance

To make the choice clearer, here’s a straightforward breakdown of how the two methods stack up against each other. This table gives you a quick snapshot of the key differences in performance, cost, and best-use cases.

| Attribute | Fusion Splicing | Mechanical Splicing |

|---|---|---|

| Performance | Extremely low signal loss (<0.1 dB) and minimal reflection. | Higher signal loss (0.3 dB+) and more reflection. |

| Durability | Permanent, robust, and stable connection resistant to environmental changes. | Less permanent; susceptible to temperature changes and vibration over time. |

| Upfront Cost | High initial investment in precision splicing machines. | Lower cost for tools and individual splice components. |

| Per-Splice Cost | Lower cost for consumable materials per splice. | Higher recurring cost per individual mechanical splice unit. |

| Required Skill | Requires highly trained and experienced technicians. | Can be performed with moderate training. |

| Best For | Core networks, long-haul links, data centers, and permanent installations. | Emergency repairs, temporary links, and some "last mile" applications. |

Ultimately, the choice isn't about which method is "better" overall, but which one is the right tool for the specific job at hand. For permanent, critical infrastructure, fusion splicing is the undisputed champion. For quick fixes and temporary links, a mechanical splice is an invaluable tool in any technician's kit.

Inside the Professional Splicing Workflow

Professional fiber splicing services are about much more than just joining two cables. It's a disciplined, multi-stage process where precision is everything, all geared toward long-term reliability. When you understand the workflow, you start to see the level of expertise required to build and maintain the high-performance networks we all depend on.

Think of it less like a simple repair and more like a surgical procedure for your network. Each step is meticulously planned and executed, building on the last to ensure the final connection is clean, strong, and virtually invisible to the data flowing through it.

Phase 1: Site Preparation and Cable Access

The real work starts long before a single fiber is touched. The first order of business is always preparation. Technicians begin with a thorough site audit, verifying cable routes, checking access points like manholes or aerial enclosures, and making sure every necessary tool and piece of safety gear is ready to go.

A clean, controlled environment is non-negotiable. Dust is the mortal enemy of a perfect splice.

Once on site, technicians carefully access the fiber optic cable. They use specialized tools to strip away the protective outer jacket, armor, and buffer tubes without nicking the delicate glass fibers inside. Each individual fiber is then painstakingly cleaned with isopropyl alcohol to remove any spec of residue that could compromise the connection.

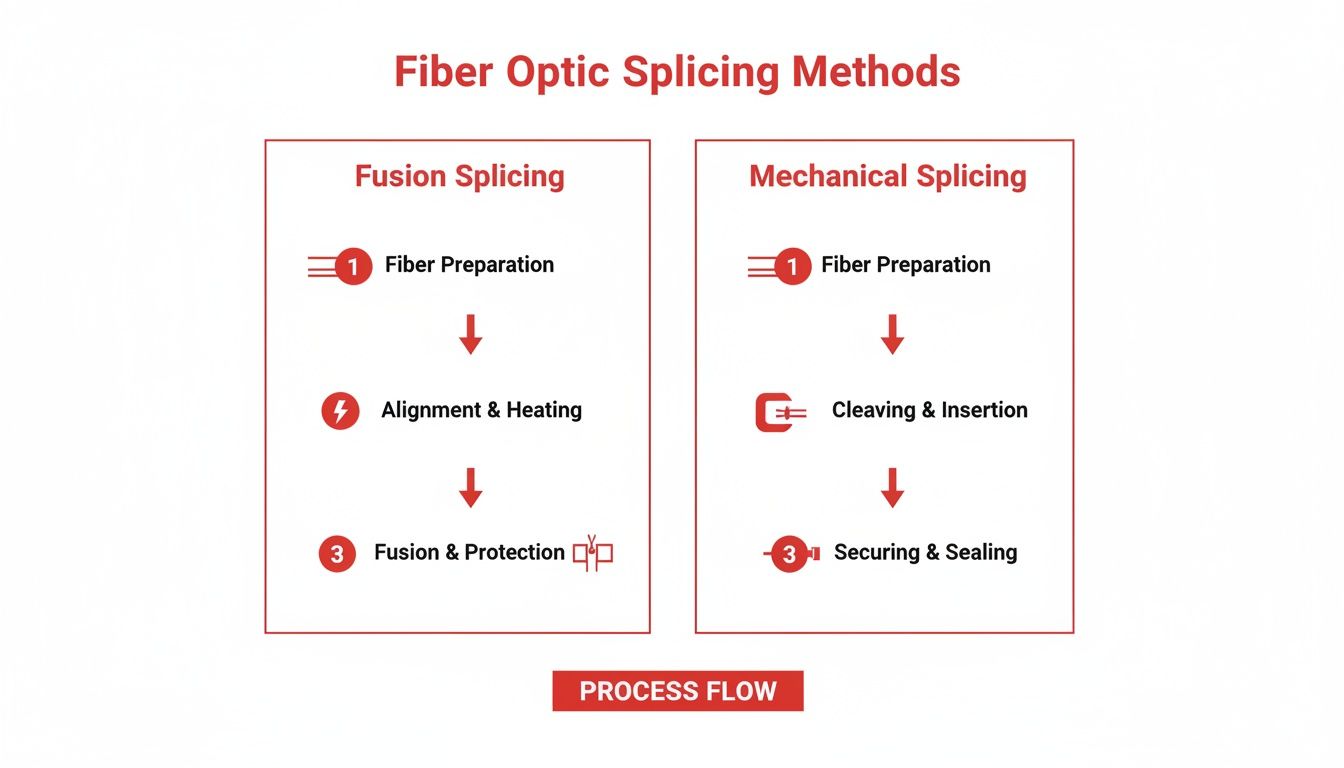

This diagram breaks down the fundamental actions in both fusion and mechanical splicing.

You can see how fusion splicing creates a permanent, welded bond, while mechanical splicing focuses on precise physical alignment—a key difference that informs when to use each method.

Phase 2: Cleaving and Splicing

With the fibers prepped, we get to the most critical step of all: cleaving. Using a high-precision cleaver, the technician scores and breaks the glass fiber to create a perfectly flat, mirror-smooth end face. This face must be exactly perpendicular to the fiber's axis.

Any imperfection here—even a microscopic chip or a slight angle—guarantees a bad splice with high signal loss.

The freshly cleaved fibers are then placed into a fusion splicer. From here, the machine’s automated system takes over for a few key seconds:

- Alignment: Tiny motors and microscopic cameras work together, aligning the fiber cores with sub-micron accuracy.

- Cleaning Burn: A small electric arc zaps away any remaining dust particles from the fiber ends.

- Fusion: A much more powerful electric arc melts the glass, permanently welding the two ends into a single, continuous strand.

The splicer even provides an immediate loss estimate, giving the technician instant feedback on the quality of the splice.

"A perfect cleave is the foundation of a great splice. It's an often-overlooked step by amateurs, but it's where professionals distinguish themselves. Without a pristine, 90-degree end face, even the most advanced fusion splicer in the world can't produce a reliable, low-loss connection."

Phase 3: Protection and Housing

A brand-new splice is incredibly fragile. To shield it from physical stress and the elements, the technician immediately slides a splice protection sleeve over the connection. This small tube, which contains a tiny steel rod for strength, is heated in an oven built right into the splicer. It shrinks down to form a rigid, protective shell around the bare fiber.

Finally, the protected splices are carefully arranged in a splice tray, which is then secured inside a larger splice enclosure. This housing is the final line of defense against moisture, temperature swings, and any physical impact, locking in the integrity of the connection for years to come. The broader toolkit for this work is also important, as detailed in our overview of fiber optic crimping and connection tools.

The job isn't done until the paperwork is. Technicians record splice locations, fiber assignments, and test results, creating an essential "as-built" record. This documentation is invaluable for future maintenance and troubleshooting, turning a simple repair into a lasting network asset.

Verifying Performance with Advanced Network Testing

A physically complete splice is only half the job. The real measure of quality for any fiber splicing service comes down to its tested performance. Without rigorous verification, a connection that looks perfect on the outside could be hiding microscopic flaws that lead to slow speeds, frustrating outages, and expensive troubleshooting later on. Advanced network testing is the critical quality assurance step that proves every connection is solid and the network performs exactly as designed.

This isn't just about a simple pass/fail grade. The verification process gives you a detailed profile of the entire fiber link, confirming that each splice meets strict industry standards. It's what gives network owners peace of mind, knowing their infrastructure is robust, reliable, and ready to handle whatever bandwidth demands come next. It’s the difference between hoping a job was done right and proving it with hard data.

The demand for this level of quality is exploding. The fiber optic cable market, which depends entirely on professional splicing, was valued at $13.45 billion in 2025 and is projected to hit $36.48 billion by 2034. This incredible growth is driven by hyperscale data centers and other critical industries that simply can't afford network imperfections.

Mapping Fiber Integrity with an OTDR

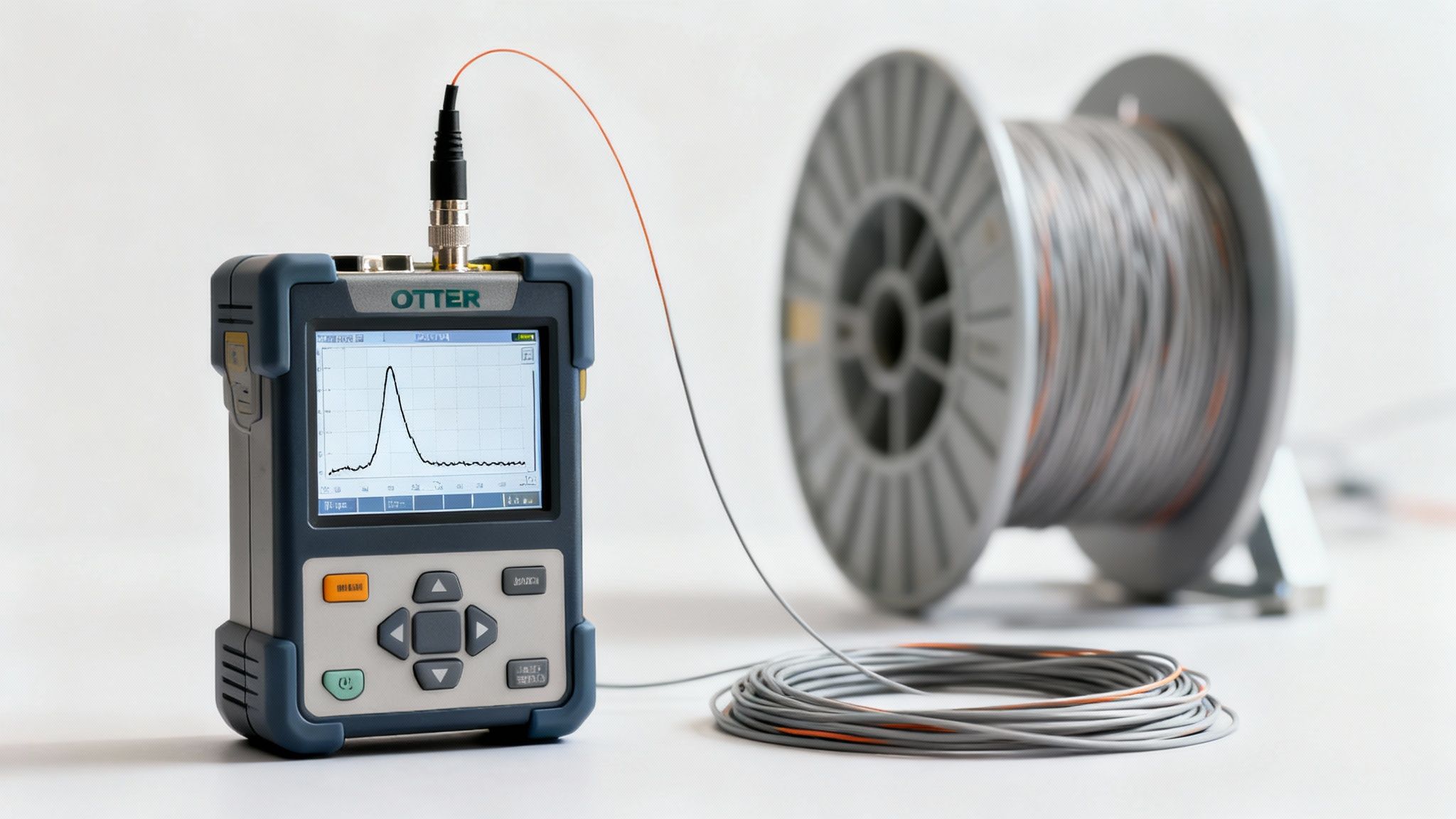

The most powerful tool in a fiber technician’s kit is the Optical Time-Domain Reflectometer (OTDR). Think of it as a sophisticated sonar system for your fiber optic cable. The OTDR shoots a powerful pulse of light down the fiber and then meticulously "listens" for the reflections that bounce back from every point along the line.

By analyzing the timing and strength of these returning signals, the OTDR creates a detailed map—or "trace"—of the entire cable run. This trace tells a technician everything they need to know:

- Pinpointing Splice Quality: It shows the exact location and performance of every splice, measuring the precise signal loss at each connection.

- Identifying Faults: It can instantly detect issues like sharp bends, breaks, or other stress points that compromise the signal, even if they are miles away.

- Verifying Cable Length: It gives an accurate measurement of the total length of the fiber segment being tested.

This diagnostic power is essential. It allows technicians to not only certify the quality of new splices but also to troubleshoot existing network problems quickly and without any guesswork.

An OTDR trace is the official birth certificate for a fiber optic link. It provides an undeniable, data-backed record of the cable's health at the moment of installation, serving as a critical baseline for all future maintenance and performance verification.

Measuring Critical Performance Metrics

While the OTDR gives you the big picture, two specific metrics are the final judges of splice quality: Insertion Loss (IL) and Optical Return Loss (ORL). Getting a handle on these values is the key to understanding test reports and holding your service provider accountable. These metrics are fundamental to ensuring that every connection works flawlessly, as you can explore further in our guide on how fiber optic signals are transmitted.

Insertion Loss (IL)

This is the most direct measurement of a splice's quality. It tells you exactly how much signal strength is lost as light passes through the connection. With IL, a lower number is always better—it means more of the original signal is successfully making it to the other end.

- Excellent Splice: < 0.1 dB

- Acceptable Splice: 0.1 dB to 0.3 dB

- Poor Splice: > 0.3 dB (This requires re-splicing, no exceptions)

Optical Return Loss (ORL)

This metric measures the amount of light that is reflected back toward the source from the splice point. High reflection is a major problem because it can destabilize the sensitive laser light sources and corrupt the data signal, leading to errors. For ORL, a higher number is better, as it indicates less light is being reflected.

Professional fiber splicing services will use an OTDR in combination with an Optical Loss Test Set (OLTS) to get precise IL and ORL readings. This two-pronged testing approach removes all doubt, certifying that every connection is optimized for maximum signal strength, clarity, and long-term network stability.

Decoding the Costs of a Splicing Project

When you're looking at a quote for a professional fiber splicing service, it’s easy to focus on the per-splice price. But the reality is, that number is just the tip of the iceberg. The final investment is a complex calculation based on the project's scale, the working environment, and just how rigorous your testing requirements are. Getting a handle on these variables early on is key to budgeting accurately and comparing quotes apples-to-apples.

The most obvious cost driver is, of course, the sheer volume of work. A project splicing a 288-count fiber cable is a completely different beast than one involving a simple 12-count cable. But it's not a simple matter of multiplication.

The Impact of Project Scale and Fiber Count

The total number of splices needed sets the baseline for any cost estimate. Most splicing providers will structure their pricing around volume, and you'll often see a lower per-splice rate for bigger projects. It just makes sense—splicing thousands of fibers in a high-count backbone cable has a different cost structure than tackling a handful of splices in a smaller lateral line.

Efficiency plays a huge role here, too. A technician who can set up once at a single location with a high fiber count can work far more efficiently than one who has to travel to ten different sites to perform just a few splices at each.

The true cost of a splice isn't just the physical act itself. It's the entire ecosystem of logistics, prep work, and verification that surrounds it. From how hard it is to access the work site to the level of testing required, every factor shapes the final price tag.

Splicing Environment and Location

Where the work actually takes place can dramatically swing the cost and timeline. There’s a world of difference between splicing in a pristine, climate-controlled data center and doing the same job in a cramped manhole or high up in a bucket truck in the middle of a storm.

- Controlled Environments: Indoor spots like data centers or telecom shelters are the ideal. They’re clean, well-lit, and shielded from the elements, which lets technicians work with maximum precision and speed.

- Outdoor or Aerial Deployments: Taking the work outside to a utility pole or down into a subterranean vault introduces a ton of complexity. Technicians have to deal with weather, manage traffic, and navigate safety hazards, all of which add time and, consequently, money.

- Emergency Call-Outs: When a line goes down and you need an emergency repair, expect to pay a premium. Immediate mobilization and the pressure to restore service mean labor rates for after-hours or emergency work can be 1.5x to 2x the standard cost.

When you're trying to nail down the financials, it's critical to use effective project cost estimation strategies that properly account for these kinds of environmental variables.

Specialized Testing and Documentation Requirements

The job isn't done when the last fiber is fused. It's done when that splice is tested, proven, and properly documented. The depth of that testing is a major cost factor. While basic OTDR testing on a single wavelength is pretty standard, some projects demand a much higher level of proof.

For example, a client might require bidirectional OTDR testing or tests on multiple wavelengths to guarantee performance for different types of network traffic. Every extra test run adds to the technician’s time on-site and requires specific gear, which naturally bumps up the budget.

The same goes for documentation. A simple pass/fail sheet is one thing. But creating detailed "as-built" documents—complete with annotated OTDR traces, diagrams of every splice location, and fiber-by-fiber records—is a significant amount of post-splicing work. That level of detail is gold for future network maintenance and troubleshooting, but it definitely adds to the upfront project cost. Understanding these components helps you have a much more productive conversation with potential providers, making sure the final quote truly matches what your network needs.

How to Select the Right Fiber Splicing Partner

Choosing a company for your fiber splicing services isn't just about finding the lowest bidder. It’s about forging a partnership that safeguards your network’s future. Think of it this way: a great partner is an extension of your own team, while a bad one can bury latent defects in your infrastructure that will inevitably surface as expensive outages down the road. To find a true expert, you have to look beyond the price tag.

The real value of a splicing provider comes down to two things: the skill of their technicians and the quality of their gear. Your vetting process should start with their people. Look for technicians with respected industry certifications, like those from the Fiber Optic Association (FOA). These credentials aren't just pieces of paper; they prove a commitment to industry-wide best practices.

Evaluating Technical Expertise and Equipment

You need to ask pointed questions about the tools they bring to the job. Top-tier providers don't skimp here—they invest in high-end, regularly calibrated fusion splicers and OTDRs from trusted manufacturers. This isn't just about having shiny new toys; it directly translates into lower-loss splices, more accurate test results, and a far more reliable network for you.

Experience is just as crucial. Ask for their track record on projects that mirror yours in both scale and complexity. A team that specializes in high-density data center work will have a completely different skillset than one that primarily handles aerial Fiber-to-the-Home (FTTH) deployments. You want the team that has already solved the problems you’re about to face.

A provider's safety record tells you a lot about their discipline and professionalism. A low Experience Modification Rate (EMR) and a well-documented safety program aren't just nice-to-haves—they should be deal-breakers for any critical infrastructure project.

Assessing Communication and Documentation Practices

Beyond the technical work, how do they handle communication and paperwork? A professional partner keeps you in the loop with clear, consistent updates and delivers meticulous records when the job is done. This means you should expect detailed "as-built" documentation, complete with annotated OTDR traces for every single splice. That paperwork becomes your roadmap for any future maintenance or troubleshooting.

Finally, take a look at their understanding of the broader market. The global appetite for fiber components is massive—the Asia-Pacific region alone is projected to account for 38.74% of the market by 2025, largely due to huge infrastructure rollouts. A partner who grasps these global supply chain dynamics is better positioned to navigate potential hurdles and keep your project on track. You can dig into more data about the global fiber component market on Mordor Intelligence.

When you're making your final choice, make sure your checklist prioritizes these areas. It’s the only way to find a partner who is truly invested in maximizing your network’s performance for the long haul.

Common Questions We Hear About Fiber Splicing

Even after you've got the basics down, real-world questions always pop up when it's time to get a fiber project off the ground. Let's tackle some of the most common things people ask us about professional fiber splicing services, focusing on the practical side of things for network operators and project managers.

How Long Does It Actually Take to Splice a Fiber?

In a perfect lab setting, a top-notch technician might knock out a single fusion splice in less than a minute. But out in the field? It’s a completely different story.

Getting the job done right involves a whole lot more than just the splice itself. We have to safely get to the cable, strip back all the protective layers, and then clean every single strand of glass with surgical precision. After the splice, each one gets its own heat-shrink sleeve for protection and has to be neatly tucked into a splice tray. For something like a 144-fiber line, you’re easily looking at several hours from start to finish. Things like bad weather, tough-to-reach locations (think working in a bucket truck versus a clean, climate-controlled vault), and rigorous testing can really add to the clock.

What's a "Good" Signal Loss for a Fusion Splice?

The official industry standard for a quality fusion splice is a signal loss of 0.1 decibels (dB) or less. That’s the baseline. However, any crew worth their salt will aim for an even tighter spec, usually shooting for a loss under 0.05 dB. This isn’t just about showing off; it’s about building a robust network that can handle future speed increases without a hitch.

An OTDR test tells the final story. If any splice shows a loss higher than the project’s limit, it gets redone. We re-cleave it and re-splice it, period. A tiny bit of signal loss might seem insignificant, but those small losses add up and can degrade the entire network over time. This is one area where you simply can't cut corners.

Can You Splice Different Kinds of Fiber Cables Together?

Technically, you can splice different fiber types, like connecting a single-mode to a multimode fiber. But should you? Absolutely not. It’s what we call a "mismatched splice," and it's a recipe for creating a massive performance bottleneck.

The problem lies in the physics. The core diameters of these fibers—the actual part that carries the light signal—are different sizes. When you join them, you create a ton of signal loss and optical reflection that can wreak havoc on your network and even destabilize sensitive equipment. The only right way to do it is to stick to splicing identical fiber types together. This ensures a clean, seamless path for your data and a reliable network for the long haul.

Your network's performance depends on the quality of its connections. Southern Tier Resources provides expert fiber splicing, testing, and documentation services to ensure your infrastructure is reliable, scalable, and built to last. Partner with us for your next network deployment or upgrade by visiting https://southerntierresources.com.