Fiber to the Home, or FTTH, represents the pinnacle of modern internet service. It's a connection where a pure fiber optic cable runs directly into your home, creating a dedicated, lightning-fast link to the digital world. This isn't just another incremental speed bump; it’s the most reliable and future-proof internet infrastructure available.

What Is Fiber to the Home and Why It Matters

Let's use a simple analogy. Think of older internet technologies like cable or DSL as shared neighborhood roads. During rush hour, everyone's traffic merges, causing congestion and slowdowns for all. Fiber to the Home is completely different. It's your own private superhighway, with multiple lanes running directly to your front door.

This direct, dedicated connection is the key. It completely bypasses the bottlenecks and signal degradation common in legacy copper networks. Data literally travels at the speed of light through impossibly thin strands of glass, immune to the electrical interference and distance issues that plague older systems.

The Real-World Impact of FTTH

You feel the difference immediately. With symmetrical speeds, your upload and download capabilities are equally impressive—something that's become essential for how we work and live online. This empowers a whole range of activities that make older connections feel ancient.

- Effortless Remote Work: Video calls are crystal-clear, and massive files transfer in seconds, not minutes. No more frozen screens or frustrating lag.

- Next-Level Entertainment: Stream multiple 8K movies at once, experience competitive online gaming without a hint of buffer, and download huge media files almost instantly.

- A Truly Smart Home: Your network can easily handle dozens of connected devices—from security cameras to smart thermostats—without ever slowing down.

- Ready for What's Next: With massive bandwidth to spare, FTTH is built to handle the demands of tomorrow's innovations, like AI applications and immersive virtual reality.

The real magic of a true FTTH network lies in its enormous capacity and incredibly low https://southerntierresources.com/goodscode/latency/411962433. This powerful combination delivers a consistently fast and responsive experience that copper-based networks just can't touch.

A Market Poised for Explosive Growth

The unstoppable demand for better internet is fueling a massive global investment boom. The worldwide FTTH market is projected to reach an incredible USD 185.45 billion by 2031, driven by a powerful 18.95% compound annual growth rate.

This isn't just a fleeting trend. It's a fundamental shift as governments and service providers race to build the infrastructure needed for remote work, advanced streaming, and the ever-growing smart home ecosystem. For a great primer on the basics, check out this guide on What Is Fiber to the Home and How Does It Work.

FTTH vs Legacy Connections At a Glance

To put it all in perspective, here’s a quick comparison of how FTTH stacks up against the technologies it’s replacing.

| Attribute | Fiber to the Home (FTTH) | Cable Internet (DOCSIS) | DSL (Digital Subscriber Line) |

|---|---|---|---|

| Technology | Pure glass fiber optic cable | Coaxial copper cable (shared line) | Copper telephone wires (shared line) |

| Typical Speeds | 1 Gbps to 10 Gbps+ (Symmetrical) | 100 Mbps to 1 Gbps (Asymmetrical) | 5 Mbps to 100 Mbps (Asymmetrical) |

| Upload vs. Download | Symmetrical (equal speeds) | Asymmetrical (upload is much slower) | Asymmetrical (upload is much slower) |

| Reliability/Interference | Extremely high; immune to electrical interference. | Moderate; susceptible to neighborhood congestion. | Low; performance degrades over distance from the hub. |

| Latency | Very Low | Low to Moderate | Moderate to High |

| Future-Proofing | Excellent; can handle future demand for decades. | Limited; requires frequent and costly node upgrades. | Poor; largely outdated technology with limited capacity. |

As you can see, the differences aren't minor—they represent a complete leap forward in performance and capability.

Understanding Core FTTH Architectures

When we talk about bringing fiber to someone's home, we're not just talking about the cable itself. We're talking about the fundamental design—the architecture—that dictates how data flows from our central office to your living room. Getting this blueprint right is everything.

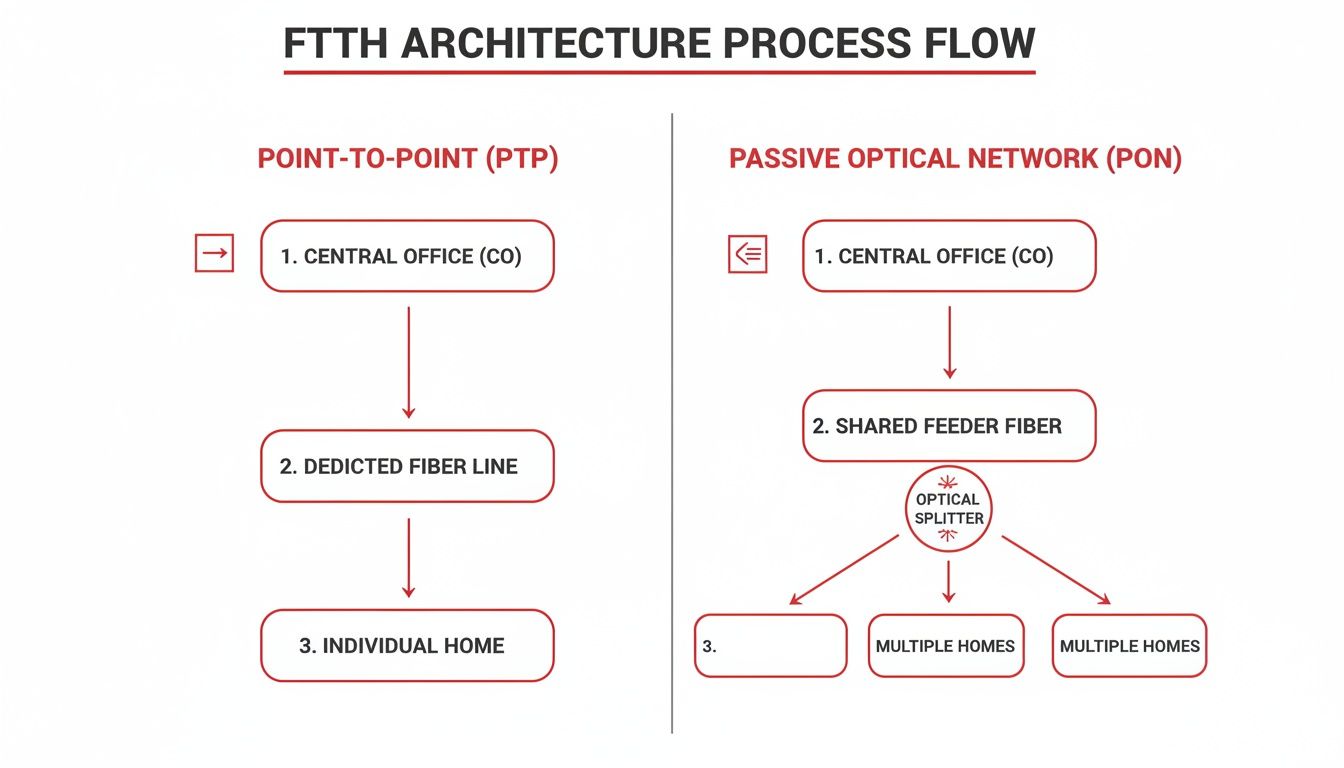

You can think of it like planning a new water system for a town. Do you give every single house its own private pipeline from the reservoir? Or do you run a massive main line and then branch off to serve each neighborhood? Both work, but they have very different implications for cost, performance, and future growth. In fiber, these two approaches are called Point-to-Point (P2P) and Passive Optical Network (PON).

The Point-to-Point (P2P) Model

The most straightforward way to build a fiber network is a Point-to-Point (P2P) architecture. It’s exactly what it sounds like: a dedicated, unbroken strand of fiber runs directly from our central office straight to a single customer.

This is the VIP treatment of internet access. You get your own private lane on the data highway, with no sharing and no contention for bandwidth with your neighbors. The result is ultimate security and guaranteed symmetrical speeds.

So, why isn't every network built this way? The cost is staggering. P2P requires a massive amount of fiber cable and a dedicated, expensive port in our central office for every single customer. It's a fantastic solution for high-value business clients or data centers that demand that level of dedicated service, but it's just not economically viable for large-scale residential rollouts.

The Passive Optical Network (PON) Model

This brings us to the workhorse of modern residential fiber to the home ftth: the Passive Optical Network, or PON. This is a much smarter, more efficient point-to-multipoint system. Instead of one fiber per home, a single fiber from our central office can serve multiple homes—often 32 or 64 at a time.

How? By using unpowered optical splitters. These simple devices take the light signal from a single fiber and divide it, sending it down multiple paths to individual customers.

Think of a PON like a tree. A thick trunk (the feeder fiber) leaves the central office. As it gets closer to a neighborhood, it splits into large branches, which then split into smaller branches, until a single leaf (the drop cable to a home) is reached. The magic is that the "splitting" happens in the field without any powered electronics.

This design is a game-changer. It drastically cuts down on the amount of fiber and central office equipment needed, which brings the cost per home down significantly. The "passive" part is also a huge operational win—no electricity needed for the splitters means lower running costs and a more resilient network.

Key Hardware in an FTTH Network

Whether it's P2P or PON, a couple of key pieces of hardware are always in the mix.

- Optical Line Terminal (OLT): This is the engine of the network, located in the service provider's central office. The OLT takes in data, converts it to light signals, and manages the entire optical network.

- Optical Network Terminal (ONT): You might also hear this called an Optical Network Unit (ONU). This is the small box installed at the customer's home that catches the light signal and turns it back into an electrical signal your router can use.

Evolving PON Standards for Greater Speed

PON technology hasn't stood still. It has continually evolved to pack more and more speed into that single fiber. The standards are all about defining the network's total shared capacity.

| PON Standard | Downstream Capacity | Upstream Capacity | Common Use Case |

|---|---|---|---|

| GPON | 2.5 Gbps | 1.25 Gbps | The long-time industry standard, perfect for delivering solid gigabit internet. |

| XG-PON | 10 Gbps | 2.5 Gbps | An upgrade supporting multi-gig speeds, great for power users and businesses. |

| XGS-PON | 10 Gbps | 10 Gbps | The current gold standard, offering symmetrical 10 Gbps speeds to future-proof networks. |

Ultimately, choosing an architecture and a PON standard is a strategic decision. It's a constant balance between the upfront deployment cost, the plan for future scalability, and the specific needs of the community we're serving. For the vast majority of residential projects, a well-designed PON architecture simply delivers the best blend of performance, reliability, and cost-efficiency.

Mapping the FTTH Deployment Lifecycle

Bringing a fiber to the home (FTTH) network to life isn’t as simple as flipping a switch. It’s a complex, multi-stage journey that takes an idea on a whiteboard and transforms it into powerful, living infrastructure. Think of it like building a brand-new highway system from scratch—every single phase has to be executed with precision to guarantee a smooth, reliable ride for everyone who uses it.

This lifecycle is a meticulously planned roadmap. Each step builds directly on the last, from the earliest feasibility studies all the way through to activating customers and handling the inevitable day-to-day maintenance. To pull it off, you need a smart mix of strategic foresight, deep technical expertise, and downright rigorous project management.

H3: Strategic Planning and Design

The real work starts long before the first shovel ever hits the ground. The strategic planning and design phase is the architectural blueprint for the entire project, and getting it right is non-negotiable. This is where we figure out if the project is even viable, what its scope will be, and how to build it in the most effective way.

This initial stage involves a lot of homework: deep market analysis to find unserved or underserved communities, demographic studies to forecast how many customers will actually sign up (the "take rate"), and a hard look at the competition. Engineers then take that data and start sketching out high-level network designs, mapping the most efficient routes for the main fiber lines and distribution hubs. It's here that you make the big architectural decisions—like choosing a Point-to-Point versus a PON model—that will impact costs and performance for years to come.

H3: Make-Ready Engineering and Permitting

With a solid design in hand, the next big hurdle is getting the physical world ready for construction. This is the make-ready engineering and permitting phase, a notoriously complex process that often feels like navigating a maze of regulations while coordinating with a dozen different entities.

For instance, if the plan is to run aerial fiber on existing utility poles, "make-ready" work ensures every pole has enough space and is strong enough to handle the new cables. That might mean moving old wires around or even replacing entire poles. At the same time, project managers are working the phones and filing paperwork to get all the necessary permits from towns, counties, and state agencies. Frankly, this is often the most unpredictable part of the whole build, where timelines can get derailed by administrative backlogs.

The diagram below breaks down the two main FTTH architectures we decide on during planning. It clearly shows the difference between a direct, dedicated connection and a shared, branching network.

As you can see, a Point-to-Point (P2P) architecture gives each user their own dedicated fiber line. In contrast, a Passive Optical Network (PON) uses splitters to serve multiple homes from a single fiber, which is a big reason it's so cost-effective for most residential projects.

H3: Outside Plant Construction

This is where the network finally starts to take shape in the real world. Outside Plant (OSP) construction is the boots-on-the-ground work of installing the miles and miles of fiber optic cable that form the network’s backbone and distribution lines.

There are two primary ways to get this done:

- Underground Installation: This involves digging trenches or using directional boring to place fiber in protective conduit safely below ground. It's more expensive and takes longer, but it provides fantastic protection from storms, vehicles, and other physical threats.

- Aerial Installation: This method uses existing utility poles to string fiber optic cables overhead. It’s much faster and more budget-friendly, especially in developed areas, but it does leave the network more exposed to bad weather and falling tree limbs.

The right choice really depends on the local terrain, existing infrastructure, budget, and what the local regulations will allow.

The following table provides a high-level overview of these critical stages, summarizing what happens in each phase and what STR brings to the table.

Key Stages of an FTTH Project Lifecycle

| Phase | Key Activities | Critical Deliverable | STR's Role |

|---|---|---|---|

| 1. Planning & Design | Market analysis, feasibility studies, high-level network design, architecture selection (PON vs. PTP), budgeting. | A comprehensive project blueprint and financial model. | Market intelligence, route optimization, architecture consulting. |

| 2. Make-Ready & Permitting | Pole loading analysis, coordinating with utility owners, securing municipal, county, and state permits. | Fully permitted and physically prepared rights-of-way. | Navigating complex regulatory environments and stakeholder coordination. |

| 3. OSP Construction | Trenching, directional boring, or aerial cable installation; placing conduits, vaults, and cabinets. | A physically installed fiber optic network infrastructure. | Project management, quality control, and construction oversight. |

| 4. Splicing & Termination | Fusion splicing of fiber optic cables at connection points; connecting fibers to panels and terminals. | A seamlessly connected optical distribution network. | Expert technicians and precision splicing equipment. |

| 5. Testing & Commissioning | End-to-end network testing with OTDRs and power meters to verify signal integrity and loss budgets. | Certified test results confirming the network meets all performance specs. | Rigorous quality assurance and performance validation. |

| 6. Documentation & O&M | Creating detailed as-built maps and records; transitioning the network to the operations team. | Accurate as-built documentation for future maintenance and expansion. | Comprehensive record-keeping and handover support. |

This structured lifecycle ensures that nothing is left to chance, transforming a complex undertaking into a manageable and successful deployment.

H3: Precision Fiber Splicing and Termination

Once the heavy construction is done, the most delicate and technical work begins. Fiber splicing is both an art and a science, requiring technicians to join two glass fibers—each thinner than a human hair—with microscopic precision. A perfect splice creates a seamless connection, allowing the light signal to pass through with virtually zero loss.

Highly skilled specialists use advanced fusion splicers to literally melt and fuse the fiber ends together. This critical work happens all over the network: at the end of each cable reel, inside distribution cabinets, and ultimately, at the connection point to a customer's home. Expertise here is everything. A single bad splice can degrade the signal for dozens of users downstream.

A well-built FTTH network is only as strong as its weakest link. Meticulous splicing and termination aren't just best practices; they are essential for delivering the consistent, high-speed experience that customers expect from a fiber connection.

H3: Rigorous Testing and Commissioning

After every cable is laid and every fiber is spliced, the network has to be put through its paces before it's ready for prime time. The testing and commissioning phase is a thorough quality control process that validates the integrity of the entire system, from the central office all the way to the subscriber.

Technicians use specialized equipment like Optical Time Domain Reflectometers (OTDRs) to send light pulses down the fiber. This allows them to "see" the entire cable run, pinpointing the exact location of any flaws, sharp bends, or sloppy splices that could weaken the signal. Power meter tests then confirm that the light reaching the customer’s location is strong enough to meet design specifications. Only when every single strand of fiber passes these stringent tests is the network officially commissioned and cleared for service.

H3: Final As-Built Documentation

The very last step is creating the definitive record of what was actually built. As-built documentation serves as a precise, detailed map of every single network component, showing the exact routes of all conduits, the locations of splice closures, and the test data for every fiber.

This documentation is incredibly valuable for the network's long-term health. When an outage occurs, it allows maintenance crews to quickly find and fix the problem, saving precious time and money. It also provides a reliable foundation for planning future expansions. Without accurate as-builts, troubleshooting becomes a frustrating and expensive guessing game. This final deliverable ensures the network isn’t just built right, but can also be managed efficiently for decades.

This comprehensive approach to deployment is fueling incredible growth. In the Americas, FTTH is hitting its stride, with the U.S. now at 56.5% of households passed by fiber in 2024 and a take-rate climbing past 45%. Canada is seeing similar momentum, having passed over 12.1 million homes with a solid 44.6% take-rate. It's all part of a major regional push to close the digital divide, and you can learn more about how this dynamism is shaping the telecom industry.

Breaking Down FTTH Project Costs and ROI

Let’s be upfront: deploying a fiber to the home ftth network is a major investment. But it’s an investment that can pay dividends for decades. To make a sound decision, you need a clear-eyed view of the entire financial picture, from the initial capital outlay to the long-term return on investment (ROI). The costs go far beyond just the price of the fiber cable itself.

For those new to fiber builds, the biggest surprise is often where the money really goes. The physical construction—what we call civil works—frequently eats up the lion's share of the budget. In fact, all the trenching, boring, and conduit installation can easily account for 50% to 75% of the total upfront cost. This is the demanding, labor-intensive part of the job, and it’s where smart, experienced planning can make the biggest dent in your budget.

Key Factors Influencing Project Costs

There’s no magic number for the cost per home passed. That figure can swing wildly based on a few critical variables on the ground. A project in a dense city will look completely different financially than one stretching across a rural county.

Here are the main cost drivers you’ll need to account for:

- Population Density: The more homes you can reach per mile of fiber, the better your cost-per-home metric will be. This is why urban builds tend to be more efficient on a per-customer basis than rural ones.

- Local Terrain: Digging through rocky ground or navigating steep hills is a world away from laying conduit in flat, soft soil. The geology of your service area has a direct impact on the bottom line.

- Installation Method: As we've touched on, the choice between aerial and underground construction is huge. Aerial is generally faster and cheaper upfront, but underground, while more expensive to install, offers far greater protection and long-term resilience.

- Permitting and Right-of-Way: The administrative maze of securing permits and access rights can inflate costs and stretch timelines in ways that catch many by surprise.

A common mistake is focusing only on the "hard costs" of a fiber build. While the civil work is the most visible expense, the time and money spent on engineering, project management, and navigating municipal bureaucracy are significant. These "soft costs" have to be baked into any realistic financial model from day one.

Understanding Timelines and Common Bottlenecks

From the first sketch to the first connected customer, a typical FTTH project can take anywhere from 12 to 36 months. The timeline really depends on the project's scale and complexity. While construction crews can move quickly, the schedule is often at the mercy of factors they can't control.

Without a doubt, the single biggest bottleneck is the permitting process. Juggling approvals from multiple jurisdictions, coordinating pole access with other utility companies, and complying with local regulations can introduce frustrating and costly delays. This is where an experienced partner who knows how to navigate these bureaucratic hurdles becomes invaluable for keeping the project moving.

Calculating the Return on Investment

At the end of the day, an FTTH network has to be financially viable. The ROI calculation really boils down to two things: how much revenue you bring in and how much you save on operations. Getting this right is absolutely essential for securing funding and proving the project’s worth.

1. Customer Adoption (Take-Rates)

The single most important revenue metric is the take-rate—the percentage of homes you pass that actually sign up for your service. A strong take-rate means you hit your revenue goals faster and shorten the path to profitability. Most financial models start with conservative projections, around 20-30% in the first couple of years, aiming for a mature network take-rate of 40-50% or higher.

2. Long-Term Operational Savings

This is where fiber truly shines over old copper or coaxial cable systems. Fiber networks are incredibly reliable, which translates directly into fewer service calls and truck rolls.

- Reduced Maintenance: Passive optical networks have very few active electronic components out in the field that can break, which dramatically cuts down on maintenance expenses.

- Lower Power Consumption: The passive design also means the network uses far less electricity to run, creating a steady stream of operational savings.

- Future-Proof Scalability: The glass you install today can support massive speed increases for decades to come. Upgrades are often as simple as swapping out electronics, which helps you avoid expensive "rip and replace" projects down the road.

By carefully analyzing these cost drivers, anticipating timelines, and building a solid ROI model, you can approach a fiber to the home ftth project with the financial clarity needed to build a successful, sustainable network for the future.

Overcoming Common FTTH Deployment Challenges

Every big infrastructure project has its share of headaches, and building a fiber to the home network is certainly no different. Getting it right isn't just about technical know-how; it's about seeing the roadblocks before you hit them and having a solid plan to navigate around them.

The goal is always a reliable, lightning-fast network. But the road to get there is paved with variables that can blow up budgets and timelines if you're not prepared. From crowded city streets to wide-open rural areas, every environment brings its own unique set of problems to solve.

Navigating Complex Permitting and Right of Way

One of the biggest—and most frequently underestimated—bottlenecks is getting the right permits and rights-of-way (ROW). Before you can lay a single foot of fiber, you need legal permission to be there. This means dealing with a dizzying maze of city, county, and state agencies, each with its own rulebook and schedule.

One missed signature or a lost email can bring the entire project to a screeching halt for weeks, sometimes months. This is where having deep local knowledge pays off. You need proactive communication, airtight documentation, and, frankly, good relationships with the people behind the desks at the permitting offices.

The smoothest fiber builds treat permitting as a critical, strategic phase—not just administrative busywork. Nail this at the beginning, and you'll keep your schedule and budget from running off the rails.

Managing Supply Chain and Labor Shortages

The global appetite for fiber has put a serious strain on supply chains. Getting your hands on essential materials like fiber optic cable, conduit, and network gear like ONTs and OLTs requires smart forecasting and solid vendor relationships. An unexpected shortage or shipping delay can create a domino effect, throwing construction schedules into chaos.

At the same time, finding enough skilled people is a real challenge. We’re seeing a significant shortage of technicians who can do the highly specialized work, especially fiber splicing. This isn't a task you can hand off to a general laborer; it takes a steady hand and a ton of training to create the perfect, light-passing connections a fiber network depends on.

Smart teams get ahead of these issues by:

- Strategic Sourcing: Ordering materials with long lead times months before they're actually needed.

- Labor Planning: Working with partners who have a roster of experienced, certified technicians ready to go.

- Inventory Management: Keeping a small stockpile of critical materials to buffer against minor delays without stopping work in the field.

Handling Unexpected Field Conditions

No matter how perfect the engineering plans look on paper, the real world always throws you a curveball. Your crew might hit a buried utility line that wasn't on any map, discover a patch of solid rock where they expected to find dirt, or find that the utility poles they planned to use are too old or crowded to support new fiber.

These are the kinds of surprises that can stop a crew dead in their tracks. The key to pushing through is having a team that can think on its feet and a clear line of communication between the field, the project managers, and the engineers. An experienced partner can assess the problem, find a safe and workable solution, and get the paperwork approved to keep things moving. This adaptability is what separates a well-run project from a chaotic one.

Delivering Turnkey FTTH Deployment Success

Pulling off a successful fiber to the home (FTTH) build is about more than just stringing cable. It demands a single, accountable partner who can steer the project from concept to completion. When you're juggling separate vendors for design, construction, and documentation, you're practically inviting delays, budget creep, and inconsistent quality into the mix.

An integrated, turnkey solution sidesteps those headaches. It turns a massive, complex undertaking into a managed, predictable process. Every step, from the first strategic blueprints and detailed engineering to the boots-on-the-ground work of make-ready and outside plant installation, is handled under one roof. That cohesion is what keeps a project on track and ensures the network that gets built is the one that was designed.

From Splicing to As-Builts

The final, most delicate stages of the deployment are where a partner’s true expertise really comes into focus. Precision fiber splicing, for instance, is absolutely critical. It has to be done by highly skilled technicians because it’s the bedrock of signal integrity and overall network reliability. Just one bad splice can hurt performance for dozens of homes, so there's simply no room for error.

Just as important is the handover of accurate as-built documentation. Think of these records as the definitive, living map of your network. They are indispensable for efficient day-to-day operations and future maintenance. Without them, trying to solve a network issue turns into a costly, time-consuming guessing game.

A successful FTTH project isn’t finished when the last cable is laid. It’s finished when a fully tested, high-performance network is handed over with accurate as-builts, ensuring its long-term health and scalability for decades to come.

The Value of an Experienced Partner

At the end of the day, building a high-performance fiber network that you can rely on requires a partner with deep, proven experience and an unshakeable commitment to safety. By managing every single phase—from navigating complex permits to lining up skilled labor—a true turnkey provider makes sure your project gets done on time and on budget.

For carriers, ISPs, and municipalities, this unified approach delivers the clarity and peace of mind needed to connect communities to the future. With one point of contact, you can focus on serving your customers, not managing a roster of contractors. For a closer look at the skills required on the ground, check out our guide on what makes a great fiber optic technician.

Your Questions About FTTH, Answered

Even after mapping out the entire deployment process, you might still have some specific questions about how an FTTH network actually works day-to-day. Let's tackle some of the most common ones to clear up any lingering confusion.

Think of this as a quick reference guide to help you weigh the practical differences and make smarter decisions about this powerful technology.

What’s the Real Difference Between FTTH and FTTN?

The biggest difference comes down to one simple thing: where the fiber stops.

With Fiber to the Home (FTTH), you get an unbroken strand of fiber running directly into the home or business. It’s a pure, dedicated connection, which is why it delivers the fastest, most reliable service possible.

Fiber to the Node (FTTN), on the other hand, is a hybrid. The fiber runs to a shared cabinet somewhere in the neighborhood, but the final connection from that cabinet to your door relies on old-school copper phone lines. That last stretch of copper is a major bottleneck, drastically cutting speeds—especially uploads—and can’t hold a candle to a true FTTH connection.

How Long Does an FTTH Network Actually Last?

The glass fiber itself is incredibly tough, with a functional lifespan of over 25 years. Unlike copper cables that corrode and suffer from electrical interference, fiber is immune to those issues, making it a truly long-term asset.

While the physical fiber in the ground will last for decades, the electronics that light it up (like the equipment in your home and at the central office) are usually swapped out every 5 to 10 years. This lets the network keep up with new speed demands and services without the massive expense of digging up and replacing the core infrastructure. The fiber itself is ready for whatever innovations come next.

Is It Better to Bury Fiber or Run It on Poles?

There’s no single "better" way; it's all about picking the right tool for the job. Each installation method has its own clear pros and cons.

- Underground Fiber: Burying the cable offers the ultimate protection from storms, car accidents, and vandalism, making it incredibly reliable. The downside? Trenching and boring are expensive and slow, often becoming a major factor in the project's budget and timeline.

- Aerial Fiber: Stringing fiber on existing utility poles is much faster and more cost-effective. The trade-off, of course, is that it’s exposed to high winds, falling tree limbs, and other physical risks.

The choice between underground and aerial deployment is a strategic one. It's a constant balance of upfront cost and speed versus long-term durability and maintenance. Your local terrain, budget constraints, and city regulations are what ultimately drive the decision.

At Southern Tier Resources, we navigate these complexities every day, delivering end-to-end fiber deployment services built for performance and longevity. From initial engineering and permitting to expert construction and meticulous documentation, we are the trusted partner for building the next generation of digital infrastructure. Learn more about our turnkey FTTH solutions.