Every video call, cloud application, and global transaction depends on a foundation most of us never see: the network cabling infrastructure. This isn't just a jumble of wires; it's a precisely engineered system that acts as the central nervous system for all our digital communication. It's the physical layer that dictates speed, reliability, and the potential for future growth.

The Unseen Foundation of Digital Communication

The best way to think about a well-designed cabling infrastructure is to compare it to a national highway system. When planned with care, it lets enormous amounts of data traffic flow smoothly from point A to point B without hitting a snag.

On the flip side, an unplanned, haphazard approach is like a city with nothing but dirt roads and no traffic lights. It doesn't take long for everything to grind to a halt, creating bottlenecks and frustrating delays. For data center operators, internet service providers, and telecom carriers, getting this physical layer right is directly tied to uptime and performance.

A tangled mess of cables simply can't handle the demands of today's operations. This is where structured cabling comes in, providing a standardized, organized framework for this critical foundation. This methodical approach ensures the system is not just reliable today but is also ready for whatever technology comes next.

Why a Structured Approach Matters

The difference between a "rat's nest" of wires and a professional installation is about more than just looking good—it impacts every single aspect of network performance. For any large-scale operator, the benefits are clear and measurable. A structured system delivers:

- Predictable Performance: When you stick to industry standards for installation and termination, signals travel with minimal interference. The result is consistent speed and low latency.

- Simplified Troubleshooting: Problems are inevitable. With clear labeling and documentation, technicians can isolate issues in minutes instead of hours, dramatically cutting down on expensive downtime.

- Future-Ready Scalability: A modular design makes upgrades straightforward. Adding new servers or moving from 100G to 400G becomes a manageable project instead of a complete, network-wide overhaul.

A robust network cabling infrastructure is the bedrock of digital services. It's an asset that, when built correctly, pays dividends in reliability and operational efficiency for years to come. Neglecting it is like building a skyscraper on a weak foundation—failure is not a matter of if, but when.

Ultimately, you have to see your cabling infrastructure not as a cost center, but as a strategic asset. From the massive undersea cables connecting continents to the fiber optic runs inside a hyperscale data center, this physical layer is what makes our connected world possible.

Understanding its components, design principles, and best practices is essential for anyone responsible for delivering dependable digital services. This guide will walk you through the practical insights needed to build and maintain a network foundation that stands the test of time.

Choosing Between Fiber Optics and Copper Cabling

When you’re mapping out a network’s physical layer, the choice between fiber optics and copper is one of the first and most critical decisions you'll make. This isn't a simple "which is better?" question. It's about picking the right tool for the right job. Think of it this way: fiber is the interstate highway system for your data, built for speed and long distances, while copper is the network of city streets—essential for connecting individual destinations.

Copper cabling, like the ever-reliable Category 6A (Cat6a), is still the go-to for many day-to-day applications. It’s perfect for the "last mile" inside a building, connecting desktops, VoIP phones, and wireless access points back to a local communications closet. Its main draws are straightforward: it’s cheaper and most technicians are already comfortable terminating it, which keeps installation costs down.

But copper has its limits. Since it transmits data using electrical signals, it's vulnerable to electromagnetic interference (EMI) from things like heavy machinery or even fluorescent lighting. The signal also weakens (a process called attenuation) over long distances, making copper a poor choice for connecting buildings across a campus or for building the high-capacity backbones that modern data centers demand.

The Unmatched Power of Fiber Optics

This is where fiber optic cabling completely changes the game. Instead of electricity, it uses pulses of light traveling through impossibly thin glass strands. This simple difference gives it three massive advantages: raw speed, incredible distance, and total immunity to interference.

Fiber can handle vastly more data over much greater distances without any signal loss. And because light isn't affected by electrical fields, fiber is rock-solid reliable, even in the most electrically noisy industrial environments.

These traits make fiber the undisputed champion for any network's most critical pathways. It's the standard for data center backbones, links between buildings, and the massive long-haul networks that form the internet's skeleton. While the initial investment can be higher, the payoff in performance and longevity is almost always worth it.

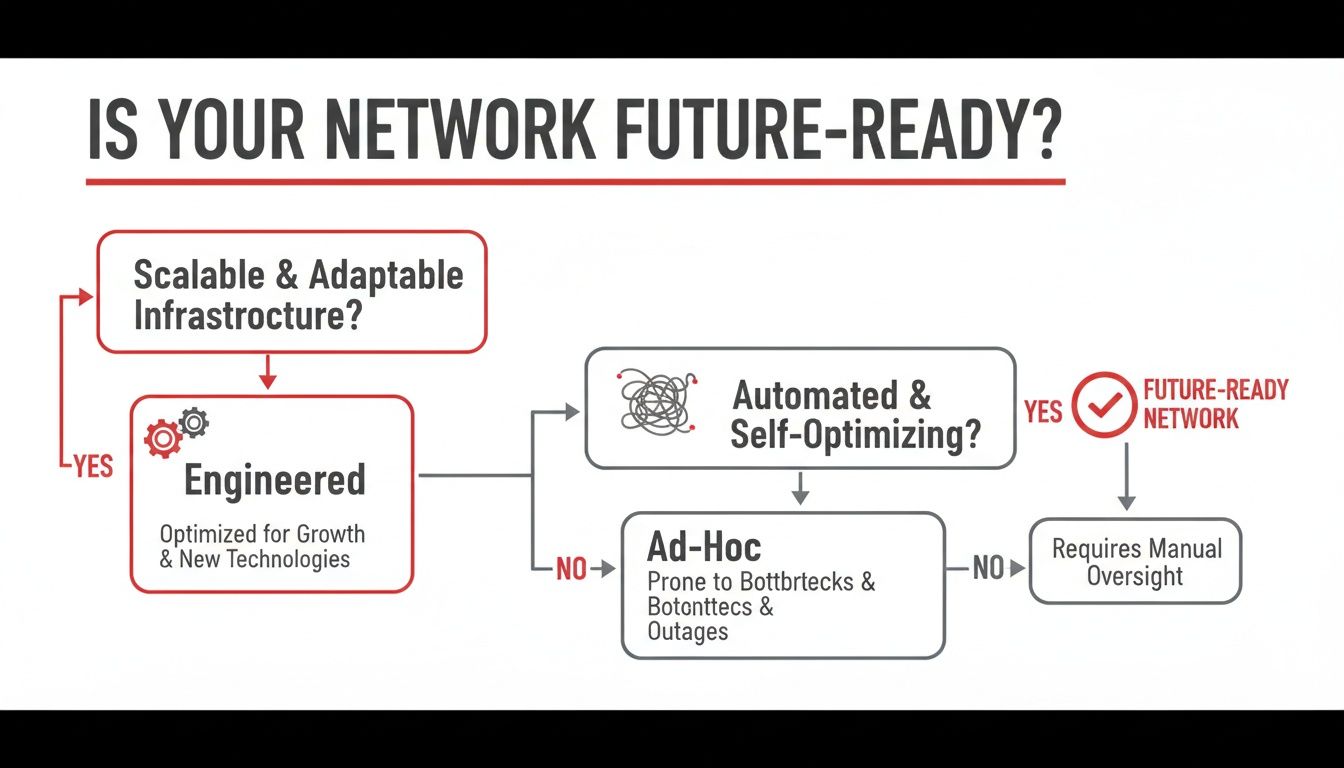

This flowchart helps illustrate the kind of strategic thinking that goes into building a network that’s ready for tomorrow's demands, not just today's.

The takeaway here is that a well-engineered plan avoids the expensive chaos that comes from patching together an infrastructure as an afterthought.

Strategic Roles in a Hybrid Infrastructure

In the real world, you rarely see a network that's 100% fiber or 100% copper. The smartest designs use both in a tiered approach that balances performance with cost.

- Fiber for the Backbone: You’ll see high-speed fiber forming the core data highway, linking main distribution hubs and connecting different floors or buildings.

- Copper for the Edge: Once the data reaches a local closet, more affordable copper cabling takes over, branching out to connect individual user devices.

The art of network design isn’t about choosing one technology over the other. It’s about knowing exactly where to build the high-speed fiber highway and where the versatile city streets of copper will get the job done efficiently.

In the hyperscale data center world, the debate is largely over—fiber has won. It's on track to command 59.3% of the global data center cabling market by 2025. This isn't surprising when you consider the insatiable hunger for bandwidth driven by cloud computing, AI, and big data. The market itself is projected to explode from USD 7.1 billion in 2025 to USD 18.1 billion by 2035, underscoring just how central fiber has become.

For a deeper dive into the technical pros and cons, this fiber internet vs cable internet comparison is a great resource. Ultimately, making the right call requires a solid grasp of your current needs and a realistic vision for future growth—the foundation of professional broadband and telecom services.

Navigating Critical Cabling Standards and Compliance

Trying to build a high-performance network without following industry standards is a recipe for disaster. It’s like an orchestra without a conductor—everyone might be playing an instrument, but the result is chaos, not music. Standards are the shared language and engineering principles that guarantee performance, safety, and, most importantly, interoperability.

These frameworks aren't just arbitrary rules; they are the distillation of decades of collective experience, rigorous testing, and hard-won lessons. Sticking to them means that a connector from one company will work perfectly with a cable from another, and the whole system will deliver the speed and reliability you paid for. For any serious carrier, data center, or ISP, compliance isn't just a box to check—it’s the bedrock of a dependable service.

Without these guidelines, every project would devolve into a custom-built mess, creating endless troubleshooting nightmares and making future upgrades nearly impossible. Standards provide a proven, repeatable path to success.

Understanding the Key Governing Bodies

When it comes to the blueprints for network cabling, two organizations stand out as the global leaders: the Telecommunications Industry Association (TIA) and the International Organization for Standardization (ISO). While their standards often cover similar ground, they cater to different geographic and regulatory environments.

-

TIA (Telecommunications Industry Association): This is the dominant standards body in North America. TIA's guidelines are known for being practical and performance-focused, covering everything from structured cabling in office buildings to the intricate designs of modern data centers.

-

ISO/IEC (International Organization for Standardization / International Electrotechnical Commission): As the name suggests, this body sets the benchmarks for the rest of the world. ISO/IEC standards provide a global framework for quality and performance, ensuring consistency across international markets.

A good way to think about it is that TIA sets the specific building codes for a project in the United States, while ISO establishes the international engineering principles that ensure a skyscraper built in Dubai meets the same fundamental safety criteria as one in Tokyo.

Core Standards You Must Know

While the full library of standards is vast, a few key documents form the foundation of almost every network design project. For anyone in this field, knowing these is non-negotiable. The absolute cornerstone is the TIA-568 series, which is the master blueprint for telecommunications cabling in commercial buildings.

This standard dictates everything from cable types and maximum distances to termination practices and testing parameters. It’s what defines the performance categories for copper cabling (like Cat6A) and the classifications for fiber, giving you a predictable benchmark for every installed link.

For mission-critical facilities, the TIA-942 Telecommunications Infrastructure Standard for Data Centers is paramount. It goes beyond basic connectivity, specifying detailed requirements for redundancy, security, and architectural design to achieve specific uptime tiers.

This standard provides a clear roadmap for building facilities that can withstand failures and meet demanding service-level agreements (SLAs). It doesn't just look at cabling; it integrates the physical pathways, cooling, and power systems that support the network. Adherence to TIA-942 is often a major selling point for colocation providers, as it signals an unwavering commitment to reliability.

To help clarify the roles of these key standards, here's a quick overview of the most common ones you'll encounter.

Key Cabling Standards at a Glance

| Standard | Governing Body | Primary Application | Key Focus Area |

|---|---|---|---|

| ANSI/TIA-568 Series | TIA | Commercial Buildings | The foundational standard for structured cabling systems, defining performance for copper and fiber components. |

| ANSI/TIA-942 | TIA | Data Centers | Comprehensive design guidelines for data centers, including topology, redundancy tiers, and environmental controls. |

| ISO/IEC 11801 | ISO/IEC | International Commercial Buildings | The global equivalent of TIA-568, providing a framework for general-purpose telecommunications cabling worldwide. |

| BICSI 002 | BICSI | Data Centers | A best-practices standard for data center design and implementation, often used alongside TIA-942 for operational excellence. |

Ultimately, for network operators, these standards transform a complex, potentially chaotic process into a predictable, engineering-driven discipline. They ensure the final product isn't just functional but is also robust, scalable, and manageable for its entire lifecycle.

Designing for Future Scalability and Growth

Anyone who builds a network just for today’s needs is setting themselves up for failure. The best network cabling infrastructures are always designed with tomorrow in mind, anticipating the inevitable growth in traffic and the constant march of new technology. Think of it like building with LEGO bricks instead of welded steel beams—you want the ability to expand and adapt without having to tear the whole thing down.

This forward-thinking approach is critical in two very different, yet equally demanding, environments: the sprawling Outside Plant (OSP) networks run by carriers and the incredibly dense, high-performance world of the modern data center. While the scale is different, the core mission is the same: build a physical layer that can evolve gracefully. Skimp on planning today, and you’re guaranteed an expensive, disruptive overhaul tomorrow.

This isn't just about dodging future expenses; it's about staying competitive. In a world where data consumption doubles at a dizzying pace, an infrastructure that can't keep up quickly becomes a serious liability.

OSP Strategies for Long-Term Expansion

For telecom carriers and city-wide broadband projects, the network literally covers the map—cities, states, sometimes even continents. Here, scalability isn't measured in years but in decades, and every design choice has massive financial consequences. Two architectural decisions, in particular, will make or break an OSP network's ability to grow.

-

Point-to-Point (P2P) vs. Passive Optical Network (PON): A P2P design gives every customer a dedicated fiber strand all the way back to a central office. It’s the ultimate in flexibility and bandwidth. In contrast, a PON architecture uses optical splitters to share a single fiber among many users. While PON is often cheaper for initial residential rollouts, P2P offers a much cleaner, simpler path for upgrading capacity or adding high-value business services down the road.

-

Laying Down Dark Fiber: This is one of the smartest moves you can make. It simply means installing more fiber strands than you need right now. These unused strands, known as dark fiber, are like pre-installed capacity waiting to be lit up. The extra cost of adding more fiber during the initial trenching is a rounding error compared to the astronomical expense of digging up streets a second time.

In OSP, you have to treat the ground itself as a one-time opportunity. Once those trenches are open, you pull as much fiber as you can. It becomes an invaluable strategic asset for decades.

This kind of long-range thinking is what supports our planet's relentless demand for data. The global undersea cable network, a massive piece of OSP infrastructure, was projected to hit a total length of 1,886,107 km by 2025, spread across 630 different cables. In that year alone, 31 new cables added 144,320 km just to keep up with cloud services and 5G backhaul. With 5G subscriptions expected to triple to 7.51 billion by 2028, the need for denser metro fiber networks is only accelerating. You can see a fantastic visualization of this global network and learn more about these incredible infrastructure projects.

Data Center Architectures for Hyperscale Growth

Inside a data center, the scalability challenge is completely different. You aren't worried about distance; you're battling extreme density and the need for constant technology upgrades. The goal is to build a physical network that lets you move smoothly from 100G to 400G and, eventually, 800G speeds without having to rip everything out.

A smart and widely used design to achieve this is the Top-of-Rack (ToR) architecture. In a ToR setup, a network switch is placed in every single server cabinet. The servers in that rack connect to it with short, easy-to-manage copper or fiber patch cords. These ToR switches then connect up to a central aggregation switch using high-speed fiber.

This modular design brings some huge advantages for scalability:

- Simplified Cabling: It massively cuts down on the mess of long, horizontal cable runs, which keeps overhead trays and underfloor plenums from becoming a congested nightmare.

- Contained Upgrades: When you need to upgrade a rack to a higher speed, the work is contained to that one cabinet and its link to the aggregation layer. You avoid a painful "rip and replace" that disrupts the whole data hall.

- Pay-as-You-Grow Model: You can add switching capacity one rack at a time, which means your capital spending stays in lockstep with actual growth, not wishful thinking.

Ultimately, whether you're designing a fiber network for an entire city or a hyperscale data center, the underlying principles of modularity and foresight are identical. A well-planned network cabling infrastructure is a direct investment in your future agility. And that planning shouldn’t stop at deployment; a truly complete strategy includes responsible IT Asset Disposition strategies for when hardware reaches its end of life, ensuring a sustainable lifecycle from day one to decommissioning.

Best Practices for Flawless Installation and Testing

A brilliant network design is just a plan on paper. The real make-or-break moment comes during the physical installation and testing, where one tiny mistake can cripple performance and haunt you for years. Getting this part right isn't just a goal—it’s the only way to make sure the network actually delivers on its promise.

This is where the theoretical blueprint becomes a tangible, high-speed reality. It demands an almost surgical precision, strict adherence to standards, and a real-world understanding of how every component works together. From the microscopic alignment of glass fibers to the big-picture organization of cable pathways, every single detail counts.

Mastering Precision Fiber Terminations

With fiber optics, the connection points are almost always the weakest link. An ultra-low-loss connection hinges entirely on the quality of the splices and connectors. The gold standard here is fusion splicing, a process where an electric arc literally melts two fiber ends together, creating a connection that's as close to seamless as you can get.

A properly executed fusion splice can result in a signal loss of less than 0.02 decibels (dB)—so small it’s practically invisible to the network. This is non-negotiable for long-haul carrier routes and high-speed data center backbones where every fraction of a decibel matters. The same precision is required for MPO/MTP connectors, which pack multiple fibers into one small interface. They’re essential for 400G and 800G networks, but their density makes them incredibly sensitive to dust. A single speck can knock out several channels at once.

Proper fiber installation is a craft that blends science and skill. The goal is to create a continuous path for light, and any imperfection—a misaligned splice, a dirty connector, a sharp bend—acts like a bottleneck, restricting the flow of data.

The Non-Negotiable Rules of Cable Management

Great cable management isn't just about making things look tidy; it's fundamental to the network's long-term health and sanity. A "rat's nest" of tangled, kinked, or over-tensioned cables directly degrades signal quality and turns future troubleshooting into a nightmare. Two rules are absolute.

- Respect the Bend Radius: Every cable has a minimum bend radius. Think of it as the tightest corner it can take without damaging its internal structure. Ignoring this is one of the most common and damaging installation mistakes, often leading to mysterious packet loss and errors that are tough to track down.

- Implement Clear Labeling: This one sounds simple, but it’s a game-changer. Every cable, port, and patch panel needs a clear, logical label at both ends. This simple act transforms a frantic, chaotic search during an outage into a calm, methodical process.

If you're looking to get your hands dirty, this guide on how to install fiber optic cable breaks down these critical steps in more detail.

Certifying Performance with Rigorous Testing

You can't manage what you don't measure. Once the physical work is done, every single link has to be put through its paces to certify it meets the performance standards laid out by groups like TIA. This isn't just a spot-check; it's a full-system validation.

Technicians rely on two key pieces of equipment for this, each with a specific job:

- Optical Loss Test Set (OLTS): This is your go-to for Tier 1 certification. It gives you a straightforward pass/fail by measuring the total signal loss (insertion loss) from one end of a link to the other.

- Optical Time Domain Reflectometer (OTDR): For a deeper dive (Tier 2 certification), the OTDR is like radar for the fiber. It sends a pulse of light down the cable and analyzes the reflections to map out the entire run, pinpointing the exact location and quality of every splice, connector, and potential fault.

Keeping detailed documentation of these test results creates a "birth certificate" for the network. This baseline data is invaluable for future maintenance, proving the quality of the install and making it exponentially faster to diagnose any problems that pop up down the road.

Avoiding Common and Costly Cabling Mistakes

Even the most carefully planned network infrastructure can fall apart because of simple, preventable mistakes. It usually comes down to focusing too much on upfront costs instead of thinking about the long-term value. This kind of shortsightedness leads to performance bottlenecks, expensive downtime, and having to rip everything out and start over way too soon. The best way to protect your investment is to learn from the mistakes others have already made.

One of the biggest blunders is underestimating how much bandwidth you'll need down the road. A system built only for today's needs is already behind the curve. For instance, a company might install Cat5e cable to save a little money, but then find out a few years later it can’t handle the 10Gbps speeds their new servers and Wi-Fi access points demand. This mistake forces a "rip and replace" job that shuts down operations and costs a fortune—far more than if they had just installed future-ready Cat6A from the get-go.

Ignoring Environmental and Material Mismatches

Another common—and dangerous—error is picking the wrong cable jacket for the job. That outer sheath is engineered for very specific environments, and if you get it wrong, you’re looking at premature failure and serious safety risks.

-

Plenum vs. Riser: Putting a standard PVC-jacketed (riser-rated) cable in a plenum space—like the area above a drop ceiling used for air circulation—is a major fire code violation. Plenum-rated cables are built with fire-retardant materials that produce far less smoke, a non-negotiable safety feature.

-

Outdoor and Direct Burial: If you run an indoor-rated cable outside, it's not going to last. UV radiation, moisture, and big temperature swings will cause the jacket to crack and fall apart, letting water seep in and ruin the copper or fiber inside. You absolutely need properly rated OSP (Outside Plant) cables for any run that leaves the building.

A network’s reliability is only as strong as its weakest component. Choosing the wrong materials or cutting corners on installation best practices introduces vulnerabilities that will inevitably lead to failure, often at the most inconvenient times.

The High Cost of Skipping Certification

Perhaps the most damaging mistake is trying to save a buck by skipping proper testing and certification. Some crews might think this final step is an optional expense and just run a quick "continuity check." This is a huge miscalculation. A continuity test just tells you that a wire is connected from end to end; it tells you absolutely nothing about its ability to actually carry high-speed data without errors.

Proper certification using tools like an OTDR for fiber or a cable analyzer for copper confirms that every single link meets strict TIA performance standards. These tests check for things like signal loss, crosstalk, and other issues that kill performance. Without this documented proof, you're flying blind. We've seen data centers wrestle with random, intermittent packet loss that’s impossible to diagnose, only to finally discover it was all caused by poorly terminated connectors—a problem a 30-second certification test would have flagged immediately. For complex projects, it's critical to partner with pros. Taking the time to review how to select from top-tier cable contractor companies can ensure your project is built to last from day one.

The global structured cabling market was valued at over USD 20 billion in 2025 and is expected to hit USD 38.47 billion by 2034. North America accounts for a massive 34% to 38.2% of that, largely driven by 5G and industrial IoT rollouts. This level of investment shows just how critical it is to get these installations right the first time. You can learn more about the growth of the structured cabling market and see why paying attention to these foundational details is so important.

Got Questions About Network Cabling? We've Got Answers.

When you're planning a major network project, a handful of questions always seem to pop up. Getting straight, practical answers is key to making the right calls—the kind that ensure your network is reliable and ready for whatever comes next. Here are a few of the most common questions we hear from clients.

What's the Real Difference Between Structured and Unstructured Cabling?

Think of structured cabling as the master-planned electrical grid for a new city. Everything is organized, standardized, and built from a single blueprint. Wires run through designated conduits, every connection is labeled, and it all terminates neatly in a central hub. This disciplined approach is the backbone of any modern, high-performance network.

Unstructured cabling is the exact opposite. It’s like running a dozen extension cords from a single wall outlet every time you need to plug something new in. It’s a point-to-point, reactive mess that might solve a problem today but creates a nightmare tomorrow. This "spaghetti" approach makes troubleshooting a guessing game, invites signal problems, and makes future upgrades incredibly difficult.

The core difference really comes down to discipline versus disorder. Structured cabling is a properly engineered system designed for scalability and reliability. Unstructured cabling is just a short-term fix that almost always creates long-term headaches.

How Often Should I Plan on Upgrading My Cabling Infrastructure?

There's no magic "best before" date on a cabling system. Instead, upgrades are driven by the real-world demands of your business and the technology you need to support, not just the calendar. A professionally designed and installed system can easily have a useful life of 10-15 years, sometimes even longer.

The true catalyst for an upgrade is when your existing cables can't keep up with the speeds you need. For instance, the jump from 10G to 40G and now 400G Ethernet has pushed data centers to swap out older copper for high-capacity fiber. The same thing happens in offices—a new Wi-Fi 6 or 7 deployment is pointless if the cables feeding the access points are a bottleneck. The decision should always be strategic, tied directly to a clear business need for more bandwidth.

What Makes a Cabling Installation "High-Quality"?

A top-tier installation is about so much more than just plugging in cables. It's a craft, and you can spot professional work by looking for three key things.

- Commitment to Standards: The job has to follow TIA and ISO standards to the letter. This covers everything from how cables are routed and secured to maintaining the proper bend radius. Following these rules is what guarantees the system actually performs the way it was designed to.

- Proof Through Testing: Every single connection needs to be tested and certified with professional-grade equipment. The installer should provide you with a complete report showing that every link passes the required performance benchmarks. This isn't just a suggestion; it's your proof of quality.

- Crystal-Clear Documentation: This is non-negotiable. It means logical, easy-to-read labels on every cable, jack, and patch panel, plus up-to-date "as-built" diagrams that map out the entire system. Good documentation turns future troubleshooting from a week-long headache into a ten-minute fix.

At Southern Tier Resources, we don't just install cables; we build future-ready network foundations. With a focus on quality, strict compliance, and smart design, we deliver the reliability your operations depend on, from complex OSP projects to data center builds. Learn how our end-to-end services can support your next project.