When you think of construction, the image of hard hats and paper blueprints probably comes to mind. But that picture is fading fast. Today, the world of tech in construction is what’s really building modern telecom, data center, and wireless networks. It’s a complete shift away from manual, often guesswork-heavy processes to a digital-first mindset that meets the relentless demand for speed, accuracy, and efficiency.

The New Blueprint for Telecom Infrastructure

The construction industry, for so long rooted in tradition, is finally in the middle of a major evolution. In this new environment, sticking with outdated processes is a losing game. Competitors are completing projects faster, safer, and with far fewer mistakes. For telecom carriers, internet service providers (ISPs), and data center operators, making this change isn't just about being modern—it's about staying in business.

The real challenge has always been wrestling with immense complexity. Think about what it takes to deploy thousands of miles of fiber or construct a hyperscale data center. You're dealing with countless variables, from mapping existing underground utilities to coordinating multiple specialized crews across huge areas. This is exactly where a digital approach moves from a "nice-to-have" to an absolute necessity.

Why Digital Tools Are No Longer Optional

The global construction technology market is on track to hit $26.7 billion by 2027. That's not just a statistic; it’s a clear signal that the industry is done hesitating and is now embracing these tools on a massive scale. For network builders, this means adopting a powerful suite of tools to smash through old roadblocks like tight deadlines, strict budgets, and a shrinking pool of skilled labor.

The benefits aren't just theoretical. They’re immediate and tangible.

- Enhanced Precision: Digital modeling and real-world scanning get rid of the guesswork. Components fit perfectly the first time, and network routes are fully optimized before a single shovel hits the ground.

- Improved Efficiency: Automation and data-driven insights drastically cut down on manual labor, minimize costly rework, and push project timelines forward.

- Greater Safety: Using drones for surveys and remote monitoring tools for site checks keeps workers out of dangerous situations, which directly reduces on-site accidents.

- Cost Reduction: When you can prevent errors before they happen and allocate resources with precision, you’re actively protecting your project's bottom line.

The question for modern infrastructure builders is no longer, “Can we afford this new software?” It’s become, “Can we afford not to make this change?” Sticking with old methods now costs far more in wasted time, materials, and missed opportunities.

A Partner-Driven Approach to Technology

In this guide, we'll explore the essential role technology now plays in construction, breaking down the specific tools that are making the biggest impact. From the foundational 'digital blueprint' of Building Information Modeling (BIM) to the predictive power of Artificial Intelligence (AI), you'll see how these have become core components for success.

We'll show you how a tech-forward partner weaves these solutions into a seamless workflow. Understanding these modern broadband and telecom services is the first step toward building the future of communication—on time, on budget, and with a level of quality that was once impossible.

Laying the Digital Foundation

Before a single shovel hits the dirt on a telecom project, the most important work is already done—digitally. We've moved far beyond the days of rolled-up 2D paper plans. Today, every successful deployment begins with an intelligent, data-rich blueprint that stops costly mistakes before they happen and sets the entire project up for success.

This digital groundwork is built on two core technologies that go hand-in-hand: Building Information Modeling (BIM) and Geographic Information Systems (GIS). BIM creates a smart 3D model of the project itself, while GIS provides the all-important real-world context for where that project will live. Together, they form a powerful planning engine, ensuring what's designed in the office can actually be built in the field.

Building Intelligence with BIM

Don't think of BIM as just a 3D drawing; it’s more like a full-dress rehearsal for your entire project, all done virtually. In a BIM model, every single component—from a tiny fiber optic conduit to a massive server rack—is a smart object loaded with critical data. This can be anything from material specs and manufacturer details to installation steps and future maintenance schedules.

This is where things get really powerful. With that level of detail, teams can run simulations and perform clash detection. This is an automated process that finds conflicts where different systems are trying to occupy the same physical space, like a new fiber route planned to go right through an existing water main.

Identifying a single clash during the digital design phase might cost a few hundred dollars to fix. Finding that same clash after construction has started can easily cost tens of thousands of dollars in rework and add weeks to your timeline.

By catching these problems on a screen instead of in a trench, BIM prevents the expensive delays and do-overs that used to be a common headache in construction. It's a fundamental shift toward proactive problem-solving.

Mapping the Real World with GIS

While BIM handles the "what," GIS provides the crucial "where." A GIS platform is so much more than a map; it’s a dynamic system that stacks layers of different data onto a geographic location. For planning any kind of telecom infrastructure, this is non-negotiable.

Picture planning a new fiber network. Using GIS, you can overlay and analyze everything you need to see:

- Existing Utilities: Map out water, gas, and electrical lines to avoid disastrous strikes.

- Topography: Understand the lay of the land—hills, valleys, and soil types—to plan for trenching or boring.

- Property Lines: Ensure every foot of construction stays within legal rights-of-way and easements.

- Environmental Zones: Pinpoint sensitive areas that need special permits or construction methods.

GIS delivers the big-picture intelligence required to make smart, strategic decisions. It helps find the most efficient route for new fiber or the best spot for a cell tower based on things like population density and signal coverage models. You can see how this data guides our approach to fiber optic construction in our detailed service overview.

Fusing BIM and GIS for a Complete Picture

The real magic happens when you bring BIM and GIS together. A GIS plan can determine the ideal path for a fiber cable, and that path data can be fed directly into the BIM model. From there, engineers can dive into the nitty-gritty, designing the exact placement of handholes, splice closures, and building connections within the detailed 3D environment.

Before we move on, let's quickly summarize these foundational tools.

Core Digital Tools in Telecom Construction

| Technology | Primary Function | Key Benefit for Telecom Projects |

|---|---|---|

| BIM (Building Information Modeling) | Creating an intelligent, data-rich 3D model of all project components. | Prevents costly physical rework by identifying design conflicts ("clashes") virtually. |

| GIS (Geographic Information Systems) | Layering critical real-world data onto a geographic map for planning. | Optimizes site selection and route planning by visualizing existing utilities, terrain, and property lines. |

By fusing these technologies, we create a seamless workflow that scales from high-level regional planning right down to the last bolt. It allows teams to simulate the entire build in a rich, data-driven sandbox, massively de-risking the project before anyone even steps on site. This digital blueprint isn't just a nice-to-have; it's the first and most critical step in delivering complex networks on time and on budget.

Gaining Unmatched Precision with Site Intelligence

Once you have a solid digital blueprint, the real work begins: connecting that plan to the physical job site. This is where modern site intelligence tools make all the difference, bridging the gap between the model and the real world with astonishing accuracy. It’s the step that ensures your carefully laid plans translate perfectly to the field, heading off the kind of costly surprises that can derail a complex telecom project.

Leading this charge are two game-changing technologies: aerial drones and LiDAR scanners. They work in tandem to capture a constant stream of high-fidelity data from the job site, feeding it right back into your BIM and GIS models. This creates a dynamic feedback loop, turning a static plan into a living document that reflects on-the-ground reality.

Drones: The Eyes in The Sky

Think of drones as your project’s rapid-response survey team. These unmanned aerial vehicles (UAVs) can knock out in a few hours what used to take a ground crew days or even weeks to complete. Outfitted with high-resolution cameras and advanced sensors, they give you an invaluable bird's-eye view of every single project phase.

Drones are masters of efficiency, particularly in the early stages of a telecom deployment. They can quickly survey huge areas for route planning, capture detailed imagery of existing utility poles for make-ready engineering, and monitor construction progress without ever getting in the way of the crews below.

The impact is huge. Contractors using aerial mapping drones can survey sites up to 10 times faster than with traditional methods. We’re also seeing reports of drones cutting survey costs by 30-50% while improving accuracy to within centimeters—a critical level of detail for large-scale infrastructure. The safety benefits are just as compelling, with drone use contributing to a 25-40% reduction in on-site accidents by keeping workers out of harm's way on hazardous surveys.

LiDAR: Capturing Reality in 3D

While drones provide the broad visual context, LiDAR (Light Detection and Ranging) delivers breathtaking precision. It works by firing millions of laser pulses at an object and measuring the time it takes for the light to bounce back. The result is a “point cloud”—an incredibly dense, three-dimensional digital twin of the physical environment, accurate down to the millimeter.

This technology is a godsend for complex work like make-ready engineering and retrofits. Imagine adding new 5G equipment to a crowded cell tower or pulling fiber through a packed utility conduit; there is absolutely zero room for error. A LiDAR scan captures the exact dimensions and spatial relationships of all existing infrastructure.

By importing this hyper-accurate point cloud directly into the BIM model, engineers can digitally "test-fit" new components with complete certainty. This process confirms the new equipment will fit perfectly, long before a single piece is fabricated or shipped to the site.

This level of detail makes LiDAR an essential tool, effectively stamping out the risk of physical clashes and ensuring a smooth, first-time-right installation. For more real-world examples of how technology is driving this kind of precision on job sites, you can find great insights on Augmented Reality in Construction.

Creating a Dynamic and Self-Correcting Plan

The real power here comes from integrating these tools. The data from drones and LiDAR isn't just a one-time snapshot; it’s a continuous flow of real-world intelligence that keeps your digital blueprint perfectly synced with the job site.

- Progress Tracking: Weekly drone flights can compare the current state of construction against the BIM schedule, automatically flagging any delays or deviations from the plan.

- As-Built Accuracy: As new fiber is buried or equipment is mounted, LiDAR scans capture its precise final location. This creates a flawless as-built record for future maintenance and operations.

- Safety Audits: Drones can perform routine safety inspections, spotting potential hazards like unsecured trenches or improper equipment staging without putting an inspector in a dangerous situation.

This constant feedback loop transforms the initial plan into a dynamic, self-correcting system. It guarantees that every decision is based on the most current and accurate ground-truth data available, building a foundation of precision that holds strong through the entire project lifecycle.

Bringing It All Together: From Data to Decision-Making

If the digital blueprints and site scans are the skeleton and eyes of a modern construction project, then intelligent systems are the brain. This is the crucial point where all that carefully collected data stops being a simple record of what’s happened and starts telling us what’s going to happen. By creating a living, breathing digital copy of a physical asset and applying smart analytics, we can finally get ahead of problems, fine-tune performance, and make better decisions throughout the project’s entire life.

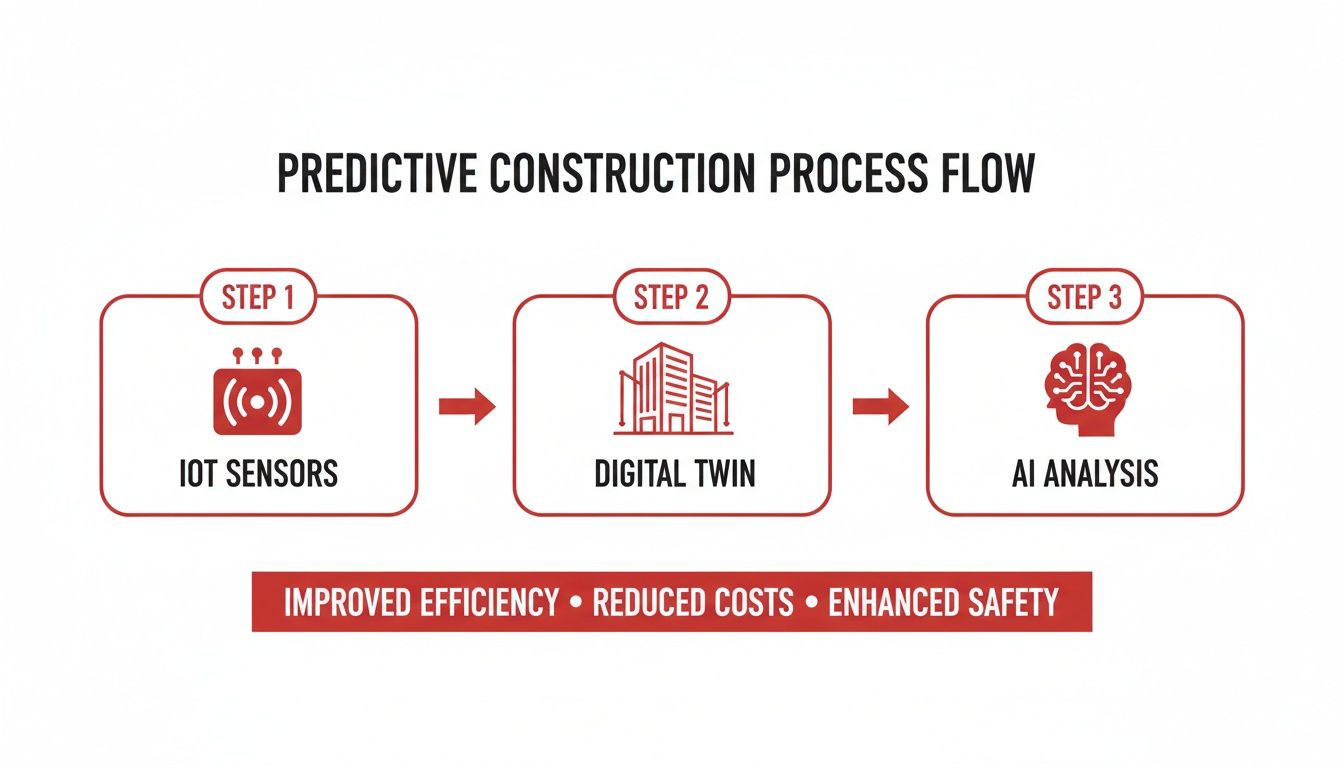

This shift from being reactive to proactive is powered by two technologies working hand-in-hand: Digital Twins and Artificial Intelligence (AI). Together, they create the analytical engine needed to solve the high-stakes challenges that telecom carriers, data center operators, and municipalities grapple with daily.

Digital Twins: The Living Virtual Replica

Picture having a perfect, virtual copy of your data center or your entire fiber network. It's not just a static 3D model but a dynamic replica that mirrors the real-world asset in real time. That's the essence of a Digital Twin. It takes the detailed foundation of a BIM model and connects it to the physical world through a network of Internet of Things (IoT) sensors.

These small sensors, attached to critical equipment, act as the asset's nervous system, constantly feeding operational data back to the virtual model.

- For a data center: IoT sensors might monitor server rack temperatures, power consumption, and humidity, flagging hotspots before they cause a failure.

- For a fiber network: They could track network traffic, signal integrity, and the physical security of crucial splice cases or access points.

- For a cell tower: You might find sensors monitoring equipment performance, the structural strain from high winds, or even ice buildup.

Because of this constant stream of live data, the Digital Twin is always an up-to-the-minute, accurate representation of the physical asset. Operators can then use this virtual environment to run simulations, stress-test changes, and predict outcomes without ever touching the real-world infrastructure. Think about it: before deploying a major network-wide software update, you could test it on the Digital Twin first to iron out any bugs and prevent a massive service outage.

A Digital Twin isn't just a model you look at; it's a model you ask questions. It lets you explore "what if" scenarios to optimize future performance and maintenance, effectively turning historical data into a roadmap for what's next.

AI: The Engine of Prediction

While the Digital Twin provides the virtual sandbox to play in, Artificial Intelligence (AI) is the engine that actually analyzes all the incoming data to find patterns and make predictions. AI algorithms can sift through enormous datasets—from IoT sensor readings to project schedules and daily progress reports—to spot subtle trends a human team would almost certainly miss. This analytical power is a massive leap forward for construction management.

AI is fueling a genuine tech renaissance in construction, with smart software now capable of forecasting project risks and sharpening our decision-making. In hyperscale data centers, AI can analyze sensor data to predict and prevent outages, boosting uptime by an estimated 15-25% while cutting lifecycle costs. For telecom carriers rolling out new wireline and wireless infrastructure, scheduling optimizations driven by AI can slash project delays by 20%—a huge advantage when skilled labor is hard to find.

Across the board, AI adoption is helping the industry keep up with the soaring number of projects. By simulating builds with digital twins, contractors can minimize material waste—with reductions of up to 30% being reported—and ensure ISPs receive perfectly accurate as-builts. You can discover more insights about these construction trends and see what experts are predicting for the near future.

This predictive capability has incredibly practical applications. An AI system might analyze daily progress reports and equipment usage logs to forecast a potential schedule slip weeks in advance, giving a project manager time to reallocate crews or adjust workflows to stay on track. In the same way, AI can analyze safety incident reports from dozens of projects to identify high-risk activities, allowing managers to implement preventative measures before an accident happens. This is how intelligent tech in construction moves us beyond simple monitoring and into the realm of true foresight.

Integrating Technology for a Seamless Project Lifecycle

The real power of tech in construction isn't about using one flashy tool; it’s about weaving them together into a single, cohesive workflow. Standalone technologies can create small pockets of efficiency, sure, but a truly integrated approach builds a powerful engine for project delivery. It's how you break down the silos that have always led to delays and budget overruns.

Think about a major fiber-to-the-home (FTTH) rollout. It all starts with GIS and drone surveys mapping out the most efficient routes and spotting potential headaches before anyone even draws a line on a plan. That crucial, real-world data flows directly into a Building Information Modeling (BIM) environment.

Inside the BIM model, every single component—from the smallest conduit to the largest cabinet—gets a digital placeholder. This lets us run clash detection and generate incredibly precise material takeoffs. The integration of technology, especially BIM, pays dividends across the entire project. To see just how deep the impact goes, you can explore these 10 Building Information Modeling Benefits.

From Digital Plan to Physical Asset

Once the design is locked in, that intelligent model becomes the playbook for the entire construction phase. AI algorithms can then analyze the project scope and resource availability to build an optimized schedule, putting crews where they need to be to minimize downtime.

As work gets underway, IoT sensors attached to equipment and installed at key points start feeding back a constant stream of data.

This process—where on-site IoT sensors feed data into a Digital Twin for AI analysis—is what creates predictive insights.

Essentially, it turns raw site information into actionable intelligence. We’re no longer just reacting to problems; we’re getting ahead of them.

All this real-time information is what fuels the project’s Digital Twin, creating a living, breathing virtual replica of the network as it comes to life. It gives project managers a crystal-clear view of progress against the plan, helping them anticipate bottlenecks and make smart, data-driven calls on the fly.

The Lifecycle Advantage of Integration

The value doesn't stop when the last cable is pulled. That completed Digital Twin becomes an invaluable operational tool for the network owner. It’s a perfectly accurate, as-built record for managing the asset, making future maintenance a breeze and simplifying upgrade planning.

Technology is not an expense on a construction project; it is the fundamental investment required to build and manage the communication networks of tomorrow. It’s the shift from building an asset to managing its entire lifecycle intelligently.

This integrated model is at the very heart of how a modern partner should operate. By managing the whole process—from initial GIS mapping to the long-term stewardship of a Digital Twin—we remove the friction points that stall projects. If you're looking to understand how we bring every piece of this puzzle together, you can learn more about our turnkey network solutions.

Your Questions About Construction Tech, Answered

Taking on new methods can feel like a big step, especially in an industry that relies on time-tested practices. To help clear things up, we've gathered the most common questions we hear from telecom carriers, data center operators, and municipalities about bringing new tech into their construction projects.

What’s the Real ROI on This Technology?

The return you see from investing in construction technology isn't just about one thing; it shows up in several ways. On the financial side, you get immediate returns from things like BIM's clash detection, which drastically cuts down on expensive rework. We also see surveying costs drop by as much as 50% when using drones, and optimized schedules mean fewer costly delays.

Operationally, the ROI comes in the form of safer job sites, higher-quality builds, and projects that are simply far more predictable. For long-life assets like fiber networks, this value just keeps growing. Having an accurate digital twin and precise as-builts makes every future maintenance call or network upgrade faster and cheaper, directly lowering your operational expenses for years to come.

How Does This Technology Help with Labor Shortages?

Technology offers a direct, powerful answer to the industry's persistent labor shortages. Automation is a huge piece of this puzzle. Tools like automated fiber testing equipment handle repetitive jobs, freeing up your skilled technicians for more complex work.

Drones and LiDAR scanners can also tackle survey and inspection tasks that would normally tie up an entire team for days.

This approach lets you shift your best people from routine data gathering to the critical, high-value roles where their expertise makes the biggest impact. Prefabrication also plays a part by moving construction from a crowded job site into a controlled, efficient factory environment.

Can Smaller Municipalities or Regional ISPs Actually Afford This?

Yes, absolutely. The smartest way to approach this is to team up with a partner who has already made the big investment in the hardware, software, and specialized training. This is a central part of the value we bring to the table.

Instead of facing a massive capital outlay for drones, LiDAR scanners, and sophisticated BIM software, you can tap directly into your partner's established tech stack. This model gives you full access to all the benefits of advanced construction technology on a per-project basis. It makes the best tools in the industry both affordable and accessible, ensuring your local infrastructure projects are built with the same precision and efficiency as the largest deployments.

At Southern Tier Resources, we build these advanced technologies into every project to deliver networks that are ready for whatever comes next. Contact us today to see how our tech-forward approach can make your next infrastructure project a success.