Think of telecom construction services as the boots-on-the-ground force that builds our digital world. While civil engineers erect bridges and skyscrapers, telecom construction crews build the physical digital infrastructure that keeps us all connected.

Building the Digital Highways That Connect Us

Telecom construction covers all the hands-on work needed to build, upgrade, and maintain the networks carrying our voice, video, and data. This isn't just about digging trenches or climbing poles; it's a highly specialized field that lays the groundwork for everything from your 5G phone service to the massive cloud platforms that power global business. The demand for these skills is exploding, all thanks to our endless appetite for faster, more reliable connections.

Picture a complex highway system. You've got massive interstates for long-haul traffic and local roads that lead right to your driveway. Telecom networks are built on a similar principle. Every project aims to create a flawless, high-speed path for data to travel from point A to point B in the blink of an eye. Getting that right requires a whole host of different skills and disciplines working together seamlessly.

The Foundation of Modern Communication

At its heart, telecom construction is where the blueprints become a real, working network. It’s the critical link between a brilliant network design on paper and a live service that people and businesses can actually rely on. The teams doing this work are responsible for all the physical tasks that make our modern lives possible.

This breaks down into a few key areas of work:

- Installing physical cables like fiber optics, which can mean trenching and boring to lay them underground or stringing them from utility poles.

- Erecting wireless structures, from the huge cell towers that provide wide-area coverage to the small cells needed for dense urban networks.

- Outfitting technical facilities, such as data centers, with the specialized power, cooling, and structured cabling that keep the core network equipment running.

- Maintaining and repairing all this infrastructure to guarantee uptime and prevent service outages that could affect millions of users.

A Growing Industry Fueled by Data Demand

The sheer scale of this work is massive, and it’s only getting bigger. The global telecom network infrastructure market was valued at USD 211.10 billion in 2025 and is expected to jump to USD 355.00 billion by 2035. That growth is being driven by huge investments from carriers and internet providers who are racing to upgrade their networks for 5G, the Internet of Things (IoT), and high-speed broadband. You can dive deeper into these telecom network infrastructure market projections to see the data for yourself.

An end-to-end construction partner takes charge of this entire complex process—from the initial engineering and permitting all the way through final testing and turnover. Having one team manage the whole lifecycle is crucial for hitting deadlines, staying on budget, and delivering a high-quality network that’s built to last.

In the end, every time you stream a movie, hop on a video call, or pull up a map on your phone, you're using a network built by the hands of telecom construction professionals. They are the invisible engine building the physical backbone of our connected world.

To better understand how these different pieces fit together, here's a quick breakdown of the core services and what they accomplish.

Overview of Core Telecom Construction Services

| Service Type | Primary Function | Key Beneficiaries |

|---|---|---|

| Fiber Optic Construction | Installing the physical fiber optic cables that form the backbone of high-speed internet and data networks. | Internet Service Providers, municipalities, large enterprises, and homeowners. |

| Make-Ready Engineering | Preparing existing utility poles and infrastructure to safely and legally accommodate new fiber or wireless attachments. | Telecom carriers, cable companies, and anyone needing to attach to existing poles. |

| Splicing & Testing | Fusing individual glass fibers together to create a continuous light path and verifying the connection's integrity. | Network operators who need to ensure signal quality and minimize data loss. |

| Tower & Small Cell Builds | Erecting the vertical structures needed for cellular and wireless communication, from large macro towers to compact small cells. | Mobile network operators (e.g., AT&T, Verizon, T-Mobile) and private network owners. |

| Data Center Fit-Outs | Equipping data center facilities with structured cabling, power systems, and server racks to house network equipment. | Cloud providers, co-location facilities, and any business with significant IT infrastructure. |

| Ongoing Maintenance | Performing routine inspections, repairs, and emergency restoration to keep the network operational and reliable. | All network owners and their end-users who depend on consistent connectivity. |

Each of these services is a critical specialty in its own right, but they all share the same goal: to build and maintain the robust infrastructure that modern communication depends on.

Understanding the Telecom Project Lifecycle

Think of a telecom construction project less like a simple task and more like a carefully choreographed performance. It starts with a detailed blueprint—the project's "sheet music"—and culminates in a high-performance network humming with data. Every phase has to flow seamlessly into the next, demanding precision, foresight, and a whole lot of coordination to pull off a successful deployment.

This isn't just about digging trenches or putting up towers. It’s a complex journey that weaves through engineering puzzles, a maze of regulations, and the sheer grit of physical construction. Successfully navigating this path is all about smart planning, and some solid construction project management tips can make all the difference in keeping every stage synchronized, on schedule, and on budget.

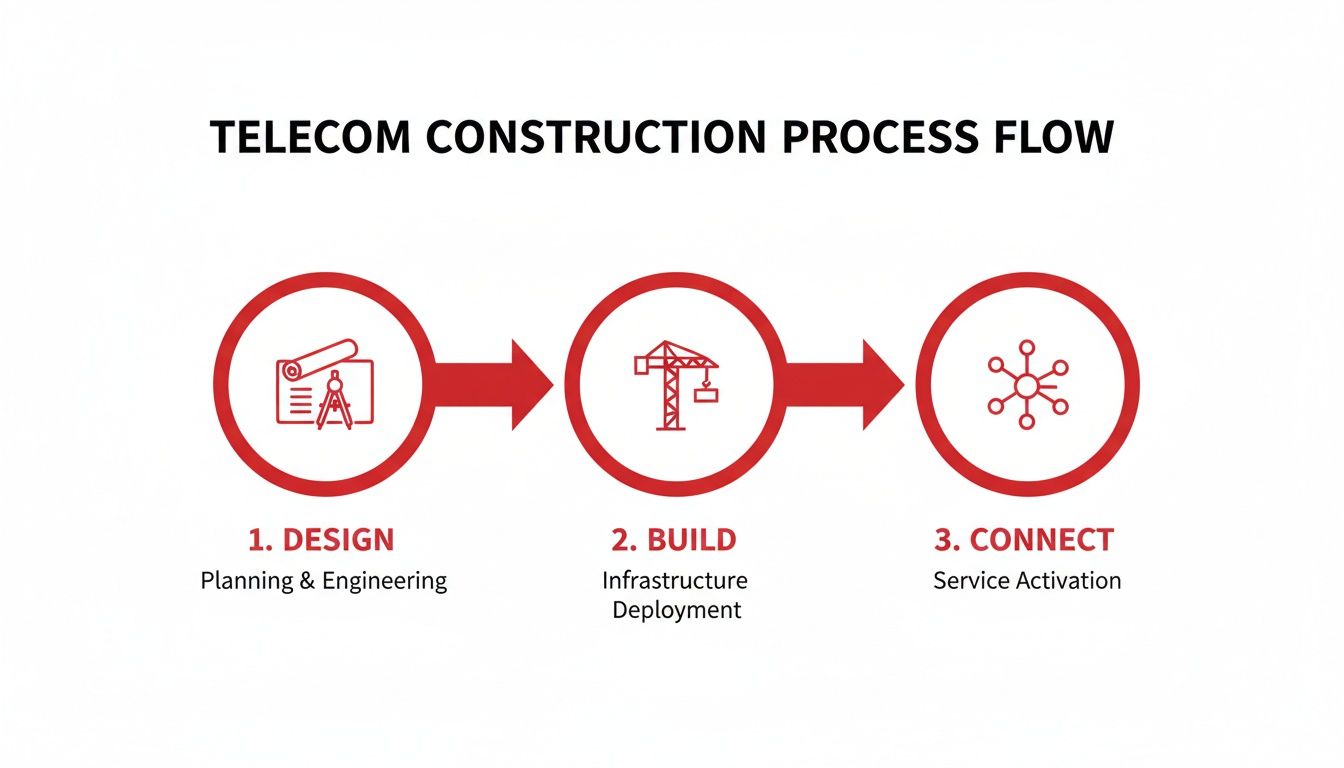

The diagram below gives you a bird's-eye view of how a typical project unfolds, from the initial idea to a fully connected, working network.

This visual breaks the entire process down into three core movements—Design, Build, and Connect—showing the logical march from planning and paperwork to physical work and final activation.

Phase 1: Engineering and Design

Long before the first shovel hits the dirt, an immense amount of work happens behind the scenes. This is the blueprint phase, where the network is meticulously designed on paper and in specialized software. Engineers are essentially drawing the map, figuring out the smartest, most efficient path to deliver connectivity. They're out in the field conducting surveys, poring over geographic data, and creating the detailed construction drawings that will guide every single person on the project.

Key activities in this stage include:

- Route Planning: This is all about finding the best path for fiber optic cables to cut costs, steer clear of obstacles, and reach the most people. It's part science, part art.

- Structural Analysis: For wireless projects, engineers have to vet potential tower sites, ensuring the ground is stable and the location is perfect for signal propagation.

- Material Specification: It’s crucial to select the right kind of cable, conduit, and hardware. The choices made here will directly impact the network's speed, reliability, and how long it lasts.

This upfront planning is what prevents eye-watering mistakes down the line. It's the strategic foundation that everything else rests on.

Phase 2: Permitting and Make-Ready

If there's one phase that tests everyone's patience, it's this one. It’s often the most time-consuming and unpredictable part of any telecom construction services project. Here, we're wading through red tape to get all the necessary legal approvals while simultaneously prepping existing infrastructure for the new gear.

Permitting means getting the green light from a whole host of entities—municipal governments, departments of transportation, environmental agencies, and sometimes, private landowners. One project can easily require dozens of separate permits, and each has its own unique process and waiting period. A delay on a single permit can bring the entire project to a grinding halt.

At the same time, Make-Ready Engineering is all about getting the physical world ready. For an aerial fiber build, that means making sure utility poles can handle the weight of new cables. This often involves the delicate work of moving existing power or communication lines—or even swapping out old poles entirely—to meet safety codes and keep the utility owners happy.

You simply can't afford to be reactive with permitting and make-ready. The best contractors have built strong relationships with local officials and utility companies over years. They know the people, they know the process, and they can anticipate what's needed, navigating the approvals much faster than a team that's new to the area.

Phase 3: Construction and Installation

Once the designs are stamped and the permits are in hand, the real fun begins. This is the most visible phase, where skilled crews start turning drawings into reality. The work itself can look very different depending on the project—it could be underground fiber, aerial cable, or a brand-new cell tower.

Common construction tasks include:

- Civil Work: This covers all the heavy lifting and earth-moving. We’re talking trenching for underground conduit, using directional boring machines to tunnel under roads without disrupting traffic, or pouring massive concrete foundations for tower sites.

- Cable Placement: Crews will either pull or "blow" fiber optic cable through the new conduit. For aerial jobs, they're carefully stringing it between utility poles.

- Splicing and Termination: This is where the real magic happens. Highly skilled technicians perform fiber splicing—the delicate art of fusing two glass fibers thinner than a human hair to create a perfect, continuous path for light. It requires microscopic precision, as the slightest mistake can cripple the signal.

- Equipment Installation: Finally, crews install the active electronics and hardware—the brains of the operation—in data centers, at the base of towers, or in street-side network cabinets.

Every single one of these steps is governed by strict safety protocols and unwavering quality standards. The goal isn't just to build a network, but to build one that will last for decades.

A Look at the Different Fields of Telecom Construction

Not all network projects are cut from the same cloth. The world of telecom construction services is incredibly varied, and each type of build requires a unique blend of skills, specialized equipment, and careful strategic planning. Getting a handle on these differences is the first step to understanding the expertise it takes to build our connected world.

Think of it this way: building a rural highway across miles of open country is a completely different challenge than engineering a multi-level interchange in a crowded city. They're both roads, sure, but the methods, materials, and headaches are worlds apart. The same holds true for the digital highways we rely on every day.

Wireline Construction: The Backbone of Broadband

Wireline construction is the heavy lifting of telecom—the actual work of laying the physical cables that form the core of our internet and communications infrastructure. Today, this work is almost entirely focused on fiber optic construction, the undisputed champion for high-speed data. These are often massive, meticulous projects demanding incredible precision and a long-term vision.

It’s like weaving a nationwide tapestry of light. Long-haul fiber projects do just that, linking cities and entire regions with huge data capacity. This work breaks down into two main approaches:

- Underground Construction: Here, crews use sophisticated methods like horizontal directional drilling (HDD) to install conduit and cable beneath roads, rivers, and environmentally sensitive areas, all with minimal surface disruption.

- Aerial Construction: This involves carefully stringing fiber optic cables along existing utility poles. It’s a job that requires tight coordination with power companies and unwavering adherence to strict safety codes.

These are the projects that make Fiber-to-the-Home (FTTH) initiatives possible, bringing blazing-fast gigabit speeds directly into our neighborhoods. A successful fiber build hinges on a deep knowledge of civil engineering, right-of-way negotiations, and the delicate craft of splicing glass strands thinner than a human hair.

The demand for this work is exploding. The market for telecom infrastructure equipment is projected to jump from USD 84.06 billion in 2025 to USD 104.35 billion by 2029, according to the latest telecommunications infrastructure report. That growth is driven by 5G rollouts and the ever-expanding Internet of Things (IoT), all of which need a rock-solid physical network to stand on.

Wireless Construction: Connecting Us on the Go

If wireline is the backbone, wireless construction provides the crucial last link that gets connectivity to our phones and other mobile devices. This field is all about verticality and strategic placement to ensure we have a strong, reliable signal wherever we are.

Wireless construction generally falls into two categories:

- Macro Towers: These are the big, traditional cell towers you see on hilltops or along the highway. Putting one up is a major construction project. It involves acquiring the site, pouring massive concrete foundations, and erecting steel lattice or monopole structures that can tower hundreds of feet in the air.

- Small Cells: As 5G networks demand more density, small cells have become vital. These are low-powered antennas, often mounted discreetly on streetlights, utility poles, or the sides of buildings. Deploying them is a more surgical operation, focused on pinpoint placement to boost capacity in high-traffic spots like stadiums, downtown areas, and busy transit corridors.

This work is a fascinating mix of heavy civil engineering and sophisticated radio frequency (RF) expertise, because the physical location and height of every antenna directly impact the network's performance.

Data Center Infrastructure: The Brain of the Network

So, if wireline networks are the highways and wireless towers are the on-ramps, data centers are the massive, bustling city hubs where all that digital traffic gets processed, stored, and directed. Building out data center infrastructure is a highly specialized discipline where precision isn’t just a goal—it’s the only acceptable standard.

This goes far beyond just running a few cables. It’s about creating a mission-critical environment to house the thousands of servers, routers, and switches that power the cloud.

Key tasks in a data center fit-out include:

- Structured Cabling: Meticulously routing and organizing thousands of fiber and copper cables into ladder racks and under raised floors. This isn't just for neatness; it's essential for proper airflow and future maintenance.

- Power and Cooling: Installing redundant power distribution units (PDUs), massive uninterruptible power supplies (UPS), and complex HVAC systems to keep the equipment running within a narrow temperature range, 24/7.

- Rack and Stack: The physical job of installing server racks and deploying network gear according to the exact, detailed specifications provided by hyperscalers and enterprise clients.

In a data center, one poorly seated cable or a mistake in the power setup can trigger catastrophic downtime for millions of users. Contractors in this space must work with surgical precision and provide flawless documentation for every single connection. Each of these fields—wireline, wireless, and data center—is a distinct specialty, but they all work together as interconnected parts of our global communications ecosystem.

Navigating Project Costs, Timelines, and Risks

Every telecom construction project is a puzzle with its own unique set of pieces, but the forces that shape its cost, schedule, and safety are remarkably consistent. Getting these three elements right from the start is what separates a successful build from a frustrating one. A good partner will walk you through these variables upfront, ensuring there are no hidden surprises later on.

Think of it like planning a cross-country road trip. You wouldn't just jump in the car; you'd map the route, estimate fuel costs, and check the weather. The same discipline applies here. Proactively managing the budget, schedule, and potential roadblocks is the hallmark of a professional telecom contractor.

Key Drivers of Project Costs

When you look at the price tag for a network build, the costs come from a few key areas. While the obvious expenses are labor and materials, some of the less-visible items—like permits and geography—can have a massive impact on the final number.

Here's where the money typically goes:

- Labor and Equipment: This is almost always the biggest line item. You're not just paying for people; you're paying for highly skilled labor—certified fiber splicers, experienced tower climbers, and seasoned equipment operators. The specialized machinery itself, from directional drills to bucket trucks, also represents a major cost.

- Materials: The price of fiber optic cable, conduit, connectors, and wireless gear is in constant flux, heavily influenced by global supply and demand. A project calling for miles of armored, direct-bury fiber will have a dramatically different material budget than one using standard aerial cable.

- Permitting and Right-of-Way (ROW): Getting the official green light to build can be surprisingly time-consuming and expensive. Municipal fees can vary wildly from one town to the next, and negotiating easements with private landowners adds another layer of financial and administrative complexity.

- Terrain and Geography: The ground itself dictates the difficulty. Building in a dense city, where underground utilities are a tangled mess, is a world apart from a straightforward rural deployment. Likewise, drilling through solid rock or navigating mountainous terrain requires specialized techniques and equipment, which always drives up the cost.

Establishing Realistic Timelines

"So, how long is this going to take?" It’s the million-dollar question, and the honest answer is: it depends entirely on the project's scale and complexity. A single small cell installation might be done in a few weeks. A 100-mile rural fiber-to-the-home build, on the other hand, can easily stretch out for more than a year.

The single biggest wildcard in most project timelines isn't the physical construction; it's the paperwork. The permitting and make-ready engineering phase can easily eat up 30-50% of the total project duration. It’s not unusual for this administrative work to last for months before a single shovel hits the ground.

This is precisely why seasoned contractors bake buffer time into their schedules. They know the process and maintain solid relationships with local authorities to keep things moving as smoothly as possible.

Identifying and Mitigating Common Risks

Every construction site comes with its share of risk. A truly professional partner doesn't just wait for problems to happen—they see them coming and have a plan in place. This foresight is about protecting the crew, the public, and the long-term integrity of the network.

Here are some of the most common risks we plan for:

- Regulatory Delays: Permitting backlogs or unexpected rejections can stop a project in its tracks. We mitigate this by submitting meticulously prepared applications early and keeping the lines of communication wide open with all permitting agencies.

- Supply Chain Disruptions: Shortages of critical components like fiber cable or antennas can cause massive delays. The solution is to order long-lead-time materials far in advance and have pre-qualified alternative suppliers ready as a backup.

- Safety Hazards: From accidental utility strikes during excavation to falls from height, the dangers are real. We tackle this head-on with a deeply ingrained safety culture, daily job site safety analyses (JSAs), and rigorous, ongoing training based on OSHA standards.

- Unforeseen Site Conditions: You never truly know what’s underground until you start digging. Discovering unmarked utilities or hitting a patch of unstable soil is a frequent challenge. Experienced crews counter this by using advanced utility locating services and having contingency construction methods ready to deploy on the fly.

How to Choose the Right Construction Partner

Picking a partner for your telecom construction services is one of the most critical decisions you’ll make for your network. This goes way beyond just comparing bids on a spreadsheet. It's a major investment in a relationship that will directly impact your project’s success, budget, and long-term performance.

A low bid from the wrong team can quickly balloon into a nightmare of delays, surprise change orders, and shoddy work. The right partner, on the other hand, acts like an extension of your own team. They bring technical expertise, proactive problem-solving, and clear communication to the job site every single day. They get that they aren't just burying cable or hanging equipment; they're building a vital asset for your business.

Verifiable Safety Record and Culture

Before you look at a single line item on a proposal, scrutinize the contractor's safety record. A strong safety culture isn't just about checking a box—it's the single best indicator of discipline, quality, and professionalism. A team that cuts corners on safety will absolutely cut corners on construction.

Start by demanding to see their Experience Modification Rate (EMR). This is a number insurance companies use to gauge risk based on past performance, and anything below 1.0 is what you want to see. Also, ask for their Total Recordable Incident Rate (TRIR) and find out about their safety training programs and daily job site analysis (JSA) protocols.

A truly safety-conscious partner doesn't just talk about safety—they live it. Their commitment will be evident in their immaculate job sites, well-maintained equipment, and the confident, methodical way their crews operate. This proactive approach is non-negotiable.

It's also crucial to have a firm grasp of General Contractor Insurance Requirements to confirm your potential partner is fully covered. Proper insurance protects their crew, your project, and your organization from any unforeseen financial risk.

In-House Capabilities and Project Management

Life gets a lot simpler when you work with a partner who has deep in-house capabilities. When one company handles the engineering, permitting, construction, and splicing, you sidestep the communication breakdowns and scheduling conflicts that plague projects relying on a web of subcontractors. To see how this works in the real world, it’s worth exploring the benefits of turnkey network solutions.

Dig into their project management process. How do they track progress, allocate resources, and keep you in the loop? Look for a partner with a proven system and a dedicated project manager who will be your single point of contact. That direct line of communication is essential for keeping the project aligned and resolving issues before they become problems.

Comprehensive Evaluation Checklist

To help you systematically vet potential partners, we've put together a checklist. This tool is designed to move your evaluation beyond vague promises and focus on the tangible evidence of a contractor's competence and reliability.

Telecom Construction Partner Evaluation Checklist

This checklist will help you ask the right questions and compare vendors on the criteria that truly matter for a successful project.

| Evaluation Category | Key Questions to Ask | Look For (Green Flags) |

|---|---|---|

| Experience & Expertise | Can you provide case studies of similar projects? Who on your team will be dedicated to our project? | Verifiable track record with projects of similar scale and complexity. Experienced, long-tenured project managers and crew leads. |

| Quality Control | What is your process for quality assurance? How do you handle final testing and documentation? | A formal, documented QA/QC process. Meticulous as-built drawings and comprehensive test results provided at project closeout. |

| Post-Project Support | What kind of warranties do you offer? How do you handle emergency restoration and ongoing maintenance? | Clear warranty terms on workmanship and materials. A dedicated team available for 24/7 emergency response. |

| Financial Stability | Can you provide financial statements or a bank letter of credit? Do you have adequate bonding capacity? | A strong balance sheet and the ability to secure performance and payment bonds appropriate for the project size. |

Using a structured approach like this ensures you’re not just hiring a contractor, but investing in a long-term partner who is equipped to bring your vision to life safely, efficiently, and to the highest standard of quality.

Your Partner in Building Future-Proof Networks

Choosing a provider for telecom construction services is a lot more than just a procurement decision. It’s a strategic investment in your network's future—its reliability, its ability to scale, and its performance over the long haul. The right partnership can take a messy, complex series of construction tasks and turn it into a single, seamless project, delivering a high-value asset built to last for decades.

Throughout this guide, we've walked through the intricate lifecycle of a network build. We've covered everything from initial design and navigating the bureaucratic maze of permitting, to the raw physical challenges of construction and the precision of final testing. A truly experienced partner doesn’t just manage these steps; they master them. They have the foresight to spot risks before they become expensive delays and the discipline to keep everything on schedule and on budget.

This level of execution is more critical now than ever. With North America holding a massive share of the global telecom infrastructure market, we're at the epicenter of advanced network construction. This boom is fueled by aggressive upgrades for 5G, IoT, and cloud services, which makes picking a truly capable partner an absolute necessity. You can get a deeper look into the trends shaping the telecom infrastructure market to see just why that expertise is so vital.

The Differentiators That Define Excellence

Once you get past the bids and proposals, the qualities that define an elite construction partner become crystal clear. These are the non-negotiable pillars that support a successful project and ensure operational excellence long after the crews have packed up.

Look for a partner who embodies:

- A Deep-Rooted Safety Culture: Safety isn't a slogan; it's a direct reflection of a company's discipline and professionalism. A verifiable safety record with a low EMR is the best indicator you have of a team that operates with precision and care, no matter the task.

- Decades of Proven Experience: There is simply no substitute for hands-on experience. Navigating different terrains, complex city codes, and the inevitable surprises that pop up on a project—that kind of problem-solving skill only comes from seasoned leadership and crews who have seen it all before.

- Meticulous Documentation: A project isn't truly done until the as-built documentation is flawless. These detailed records are absolutely essential for future maintenance, troubleshooting, and network upgrades. They're what protect your investment for its entire lifecycle.

Choosing a partner is ultimately an investment in certainty. It’s the confidence that comes from knowing your network is being built by a team that combines technical skill with a commitment to quality and an unwavering focus on safety.

Building for Tomorrow Starts Today

In an industry where technology moves at a breakneck pace, the physical infrastructure has to be built to standards that can handle what's coming next. Integrating advanced methods is key, and understanding how technology is transforming construction gives you a window into how forward-thinking partners deliver superior results. A future-proof network isn't just about the quality of the fiber or the height of the tower; it’s about the quality of the partnership that brought it to life.

Common Questions About Telecom Construction

Even the most well-thought-out network build comes with its share of questions. Let's tackle some of the most common ones we hear from clients to give you a clearer picture as you plan your project.

What's the Single Biggest Hurdle in a Fiber Build?

Hands down, the most significant and frequently underestimated challenge is securing permits and rights-of-way. It’s not the digging or the technology; it’s the paperwork and approvals.

Every project has to navigate a dense maze of requirements from municipalities, state agencies, and private landowners. If you don't get ahead of this from the very beginning, you're looking at major delays. This is where a partner with a dedicated permitting team is worth their weight in gold—their local knowledge and existing relationships can cut through red tape and keep a project moving.

How Can Make-Ready Engineering Derail a Project Timeline?

Make-ready is exactly what it sounds like: getting existing infrastructure, like utility poles, ready for new fiber. This isn't just a simple matter of attaching a new cable. It can mean shifting existing lines or even replacing entire poles to meet safety codes and weight limits, all of which requires painstaking coordination with the utility companies that own them.

Make-ready is what we call a critical-path activity. Any delay here directly pushes back the entire construction schedule. Proactive planning and solid relationships with utility owners are non-negotiable if you want to prevent this stage from becoming a major bottleneck.

What's the Difference Between Splicing and Testing?

While they happen close together, these are two distinct, critical steps that guarantee the quality of your network.

-

Splicing: This is the highly precise, physical work of joining two fiber optic cables. A skilled technician uses specialized equipment to perfectly fuse the microscopic glass strands, creating a seamless path for light to travel.

-

Testing: This is the quality control that verifies the splice was done right. Using advanced tools like an OTDR (Optical Time-Domain Reflectometer), crews measure the signal strength and look for any loss, ensuring the connection is solid before the network goes live.

A good analogy is a plumber welding two pipes together (splicing) and then running a pressure test to make sure the seam is perfect (testing). You can't have a reliable network without both.

Ready to build a network that’s reliable from day one? The expert teams at Southern Tier Resources manage every detail of the telecom construction lifecycle, from permitting and engineering to final testing. Get in touch with us today to discuss your next project.