When you think about the power grids, internet connections, and data centers that run our world, you're picturing the work of utility contracting companies. These are the specialized builders who construct and maintain the physical infrastructure we all depend on every single day. They’re the expert partners that turn complex engineering plans into the real-world lifelines of a modern society.

The Architects of Connection

Imagine a modern city as a living organism. For it to function, it needs a circulatory system—veins and arteries that deliver power, data, and resources everywhere. Utility contracting companies are the surgeons and engineers of this system. They do far more than just dig trenches or climb poles; they meticulously install the fiber optic cables for our internet, build the towers that give us wireless service, and construct the power infrastructure that keeps the lights on.

Their role is absolutely foundational. Every video call you make, movie you stream, or light switch you flip connects you to a network built and maintained by these specialized firms. They operate right at the intersection of heavy construction, precision engineering, and advanced technology, making abstract plans a tangible reality.

Bridging the Gap Between Design and Reality

Utility contractors are the ones who translate complex blueprints into functioning networks. Their work is a unique mix of rugged fieldwork and delicate precision, demanding a deep understanding of both large-scale civil engineering and the fine details of fiber optics or high-voltage power lines. This requires a skill set that goes well beyond what you'd find in general construction. For a closer look at the sheer scale of these projects, it's worth exploring the world of heavy civil construction.

Their responsibilities are broad and critical, often including:

- Installing new infrastructure, from underground fiber ducts to aerial power lines.

- Upgrading existing systems to handle the ever-growing demand for data and electricity.

- Maintaining and repairing networks to ensure reliability and prevent costly outages.

- Executing specialized projects like data center fit-outs or small-cell wireless deployments.

In essence, a utility contracting company is a force multiplier for telecom carriers, data center operators, and power companies. They provide the specialized labor, equipment, and project management expertise needed to expand and modernize critical infrastructure safely and efficiently.

To better understand their central role, let's break down their primary functions.

Key Roles of a Utility Contracting Company

The table below summarizes the core responsibilities these contractors handle and clarifies their direct impact on the infrastructure that powers our connected lives.

| Function | Description | Impact on Infrastructure |

|---|---|---|

| Fiber & Telecom Construction | Installing, splicing, and testing fiber optic networks, both underground and aerial, to expand high-speed internet and 5G coverage. | Creates the physical pathways for data, enabling everything from remote work to streaming services and IoT devices. |

| Power & Electrical Services | Building and maintaining the electrical grid, including substations, transmission lines, and underground power distribution systems. | Ensures a reliable and resilient power supply for homes, businesses, and critical facilities like hospitals and data centers. |

| Data Center & Facility Fit-Outs | Handling the complex electrical, mechanical, and low-voltage installations inside data centers and other mission-critical facilities. | Provides the core power and cooling infrastructure that keeps servers and network equipment running 24/7. |

| Wireless Infrastructure | Constructing cell towers, small cells, and distributed antenna systems (DAS) to support and expand cellular network capacity. | Improves mobile coverage and data speeds, which are essential for communication, navigation, and emergency services. |

These functions demonstrate how utility contractors are not just builders but essential partners in maintaining and advancing our society's technological and energy frameworks.

The Driving Force Behind Modern Infrastructure

The demand for these services isn't just steady—it's accelerating. As our world becomes more connected and data-hungry, the need for bigger, better, and stronger infrastructure grows exponentially.

This trend is clearly reflected in the market. Valued at over $800 billion recently, the global utility construction market is projected to surge past $1 trillion within the next decade. This incredible growth highlights just how indispensable these companies are in building the backbone of our digital future. This continuous investment ensures that the networks supporting our economy and daily lives remain reliable and ready for whatever comes next.

Core Services for Telecom and Data Center Infrastructure

Utility contracting companies are the boots on the ground, the skilled teams who take network blueprints and turn them into tangible, working infrastructure. Their services are the essential building blocks for modern connectivity, covering everything from the fiber optic cables buried under our streets to the wireless gear perched on towers above us. To really grasp their role, you have to understand the core functions that power our digital world.

Think of it like building a national highway system, but for data. You need crews to survey the land, others to pave the roads and build the bridges, and specialists to install the traffic signals. For utility contractors, the "highways" are fiber networks and power grids, and their specialized services ensure every piece of the puzzle fits perfectly and is built to last.

Preparing the Way with Make-Ready Engineering

Before you can hang even one foot of new fiber on a utility pole, a critical first step has to happen: make-ready engineering. This is far more than a quick look-see. It's a meticulous structural analysis to confirm that existing poles can handle the new weight and tension from the fiber and its hardware. It’s all about protecting public safety and the integrity of the existing grid.

Contractors get hands-on, assessing each pole’s condition, its current load, and all the existing attachments. They then engineer a solution to create space and ensure everything meets strict clearance codes. This isn't just busywork; it's the proactive effort that prevents sagging lines, overloaded poles, and the kind of costly outages that make headlines. It sets the stage for a smooth, safe network deployment.

Building the Network with Fiber Construction

With the path cleared, the real build begins. This is where utility contracting crews put their skills to the test, installing fiber networks both in the air and underground—each with its own set of challenges.

-

Aerial Construction: This is the art of stringing fiber optic cables along utility poles. It’s a job for specialized gear like bucket trucks and crews who understand the precise tensioning needed to keep the cable secure and compliant with all safety standards.

-

Underground Construction: To bury networks, contractors use advanced techniques like directional drilling. This allows them to install conduits and cables under roads, rivers, and other obstacles with minimal disruption to the surface, protecting the vital infrastructure from weather and accidents.

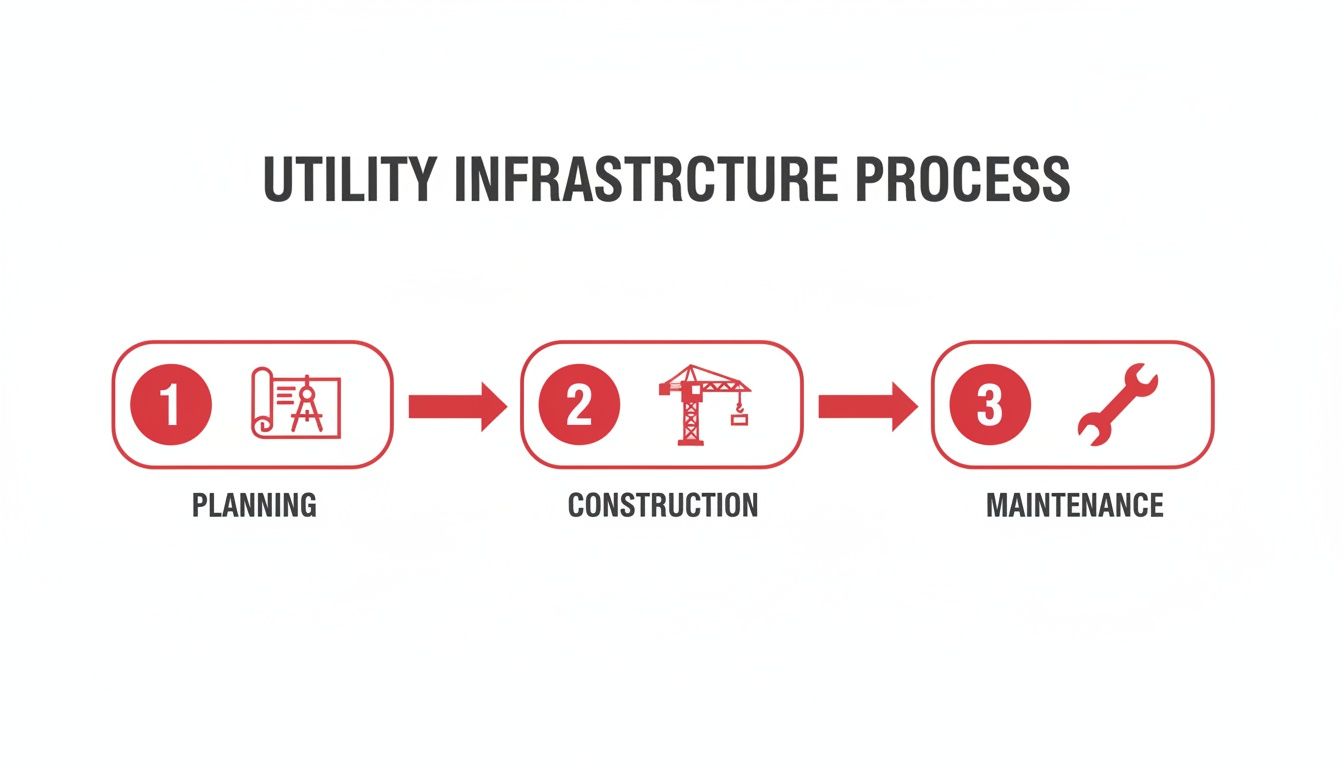

This entire process—from initial design to long-term upkeep—is a carefully managed strategy. Construction is a key phase, but it's just one part of the lifecycle of building and sustaining a reliable network.

Ensuring Data Integrity with Splicing and Testing

Just getting the fiber in the ground or on the pole isn’t the end of the story. It has to be flawlessly connected and verified to carry data without a hitch. This is the precise craft of fiber splicing and testing.

Highly skilled technicians, known as splicers, fuse individual glass fibers—each thinner than a human hair—with microscopic accuracy. The goal is to create a single, unbroken path for light signals to travel.

After the splice is made, the real test begins. Crews use sophisticated equipment like Optical Time-Domain Reflectometers (OTDRs) to check the connection's quality. This tech measures any signal loss and pinpoints imperfections, guaranteeing the network operates at peak performance right out of the gate. Without this level of quality control, even the most well-built network would fail to deliver the speed users need. You can dive deeper into the complete suite of broadband and telecom services that underpin modern connectivity.

Powering Up Critical Infrastructure

All this amazing connectivity hardware is just inert material without a steady supply of power. Utility contractors are also electrical experts, handling the crucial power installations for cell sites, data centers, and network hubs. Their work can involve anything from running conduit and installing beefy electrical panels to connecting a brand-new facility to the local power grid.

For a new data center or a 5G small cell, the power installation is the heartbeat of the entire operation. Contractors must ensure these systems are not only powerful but also resilient, often integrating backup generators and uninterruptible power supply (UPS) systems to guarantee 100% uptime.

This is high-stakes work that requires a deep knowledge of electrical codes, safety protocols, and the unique power demands of sensitive electronics. There’s simply no room for error. From constructing small cells to executing complex data center fit-outs, these services highlight the versatile and absolutely essential role utility contractors play in keeping us all connected.

How to Select the Right Utility Contracting Partner

Choosing a utility contractor is one of the most critical decisions you'll make as a project manager. This isn't just about hiring a crew; it's about forming a partnership that directly impacts your budget, your timeline, public safety, and the long-term integrity of your infrastructure. Looking past the lowest bid isn't just a good idea—it's an essential risk management strategy.

The right partner becomes a genuine extension of your team, bringing field-tested expertise, day-in-day-out reliability, and a proactive mindset to solving problems before they derail the project. A bad choice, on the other hand, almost always leads to a cascade of costly change orders, dangerous safety incidents, and infuriating delays. A systematic and thorough vetting process is simply non-negotiable.

Evaluating Safety and Compliance Records

Before you even glance at a bid or a project portfolio, start with safety. It's the absolute bedrock of utility construction. A contractor’s safety record is the clearest indicator of their operational discipline, professionalism, and overall approach to their work.

First, ask for their Experience Modification Rate (EMR). This number, calculated by the insurance industry, tells a powerful story. An EMR below 1.0 means their safety record is better than the industry average. A score above 1.0 is a warning sign, signaling a history of more frequent incidents and higher risk. It’s a quick, standardized snapshot of their performance.

But the EMR is just the beginning. Dig deeper into their entire safety program. A top-tier partner will have a robust framework that includes:

- OSHA Certifications: Their crews should hold current OSHA 10 and OSHA 30 certifications. This is the baseline for safety awareness on any job site.

- Daily Safety Briefings: How do they start the day? Ask about their "tailgate" or "toolbox" talks, where the team reviews the specific hazards for that day's tasks.

- Dedicated Safety Personnel: The best companies have a full-time safety director or manager who conducts regular, unannounced site audits. This shows they are truly invested, not just checking a box.

- Incident Reporting Protocol: Look for a transparent and well-documented process for reporting everything—including near-misses. This fosters a culture of learning and continuous improvement.

A contractor who hesitates to provide detailed safety documentation or can't articulate their safety protocols should be immediately disqualified. In this high-risk field, a casual attitude toward safety is a massive red flag.

Assessing Technical Capability and Financial Stability

Once you’re confident in their safety culture, it's time to verify they have the technical chops and financial stability to actually deliver. This means looking at what they've done, what they have, and how solid their business is.

A proven track record is your best predictor of future success. Ask for a portfolio of projects similar to yours in both scope and complexity. But don't just look at glossy photos of the finished product. Call their client references. Ask tough questions about their communication, how they handled unexpected problems, and whether they stuck to the schedule and budget. For specialized jobs, understanding the nuances of different cable contractor companies can give you a much clearer picture of their specific skills.

The utility construction world is competitive. You have global giants like Fluor Corporation and AECOM competing with highly specialized regional firms. This competition has pushed many contractors to specialize, with telecom services now making up about 62% of the market. When vetting a partner, make sure their core specialty aligns perfectly with what your project demands. You can discover more insights about the utility construction market and its key players to get a better feel for the landscape.

Finally, take a hard look at their equipment and people. A modern, well-maintained fleet—from bucket trucks to directional drills—shows a company that invests in reliability and getting the job done right. At the same time, ask about the training and certifications of their field crews. You want to know that the people executing the work are true professionals. This is the due diligence that separates a good-enough partner from a great one.

Defining Success With KPIs and Service Level Agreements

Once you've picked your partner, the real work begins. A strong partnership isn't built on handshakes and hope; it's forged with clear, measurable expectations. This is where Key Performance Indicators (KPIs) and Service Level Agreements (SLAs) become your best friends. They turn abstract goals into hard numbers, making sure everyone agrees on what "a job well done" actually looks like.

Trying to manage a complex infrastructure project without them is like flying blind. KPIs and SLAs provide the data-driven clarity you need to keep your contractor accountable, manage performance proactively, and stop small hiccups from turning into big problems. They create a transparent foundation where both you and your contractor can thrive.

Key Performance Indicators That Actually Matter

Let's be honest—not all metrics are useful. For utility contracting, you need to zero in on KPIs that give you a real-time pulse on project health, focusing on safety, quality, and efficiency. Vague metrics are a waste of time; your KPIs need to be specific to the high-stakes work being done in the field.

Think of it as the project's dashboard. Good KPIs let you spot trends, flag potential issues before they derail the timeline, and make smart decisions based on objective data, not just a gut feeling.

Here are a few of the most important ones to track:

- Safety Incident Rate: This is the big one. You should be tracking metrics like the Total Recordable Incident Rate (TRIR) and Lost Time Incident Rate (LTIR). A consistently low rate is a clear sign of a contractor who walks the walk on safety culture.

- Schedule Adherence: This is simple but powerful: what percentage of milestones are hit on time? This KPI tells you a lot about your contractor’s ability to plan, manage resources, and execute.

- Budget Variance: How closely does spending track to the plan? Monitoring this helps you catch scope creep or hidden inefficiencies before they blow up the budget.

- First-Pass Yield (FPY): For any technical work like fiber splicing or equipment testing, this metric is gold. It measures the percentage of tasks that pass inspection on the first try, directly reflecting the skill and quality of the field crews.

A well-designed KPI dashboard shouldn't be a secret. Review it regularly with your contractor. When you make performance management a shared goal instead of a one-sided report card, you build true accountability and partnership.

To get a clearer picture, here’s a breakdown of the KPIs that should be on every project manager’s radar.

Essential KPIs for Utility Contracting Projects

This table outlines some of the most critical performance indicators, categorized by the area they impact most.

| Category | KPI Example | Why It Matters |

|---|---|---|

| Safety & Compliance | Total Recordable Incident Rate (TRIR) | The ultimate measure of a safe worksite. A low TRIR shows a commitment to protecting people and minimizing risk. |

| Project Efficiency | Schedule Adherence (%) | Indicates the contractor's ability to plan, manage crews, and meet deadlines, which is crucial for project ROI. |

| Financial Control | Budget Variance (%) | Keeps projects financially healthy by flagging over- or under-spending early, preventing costly surprises. |

| Quality of Work | First-Pass Yield (FPY) | A direct reflection of technician skill and quality control. High FPY means less rework, lower costs, and faster completion. |

| Customer Impact | Rework Rate (%) | Measures the percentage of work that has to be redone. A low rate means the job was done right the first time, saving time and money. |

Monitoring these metrics provides a clear, data-backed view of your project's health, moving conversations from subjective feelings to objective facts.

Structuring a Powerful Service Level Agreement

If KPIs measure what gets done, the Service Level Agreement (SLA) defines how it gets done. A solid SLA moves beyond boilerplate contract clauses to set firm, enforceable standards for service delivery, response times, and problem-solving. It's your rulebook for the engagement.

A weak SLA is an invitation for ambiguity and conflict. A strong one removes any guesswork, clearly outlining expectations and the consequences for both meeting and missing them.

A truly robust SLA will always include specifics on:

- Issue Response and Resolution Times: Don't just say "respond quickly." Define severity levels—a critical network outage is different from a minor cosmetic issue—and assign hard deadlines. For example, a critical outage might demand a 1-hour response and a 4-hour resolution.

- Maintenance Protocols: Spell out the schedule and exact procedures for any routine maintenance. What documentation is required? Who signs off on it? Put it in the SLA.

- Communication and Reporting: How often will you get progress reports, and what will they look like? What's the meeting cadence? Who is the point of contact for an after-hours emergency?

- Performance Penalties and Incentives: This is where you connect the dots between KPIs and the SLA. Tie performance to real-world consequences. This could mean financial penalties for missing safety targets or a bonus for finishing a crucial phase ahead of schedule.

By getting these details down on paper from the start, your SLA becomes more than just a contract—it's a critical risk management tool. When challenges pop up (and they always do), you'll already have an agreed-upon game plan ready to go, keeping the project moving forward.

Navigating Pricing Models and Project Risks

Getting the financial framework right is just as important as managing the physical construction of a utility project. The pricing model you and your contractor agree on will have a huge impact on your budget, risk exposure, and overall flexibility. At the same time, without a solid plan for managing risk, even the most carefully planned projects can get derailed by unexpected problems, leading to expensive delays and frustrating disputes.

Let's be realistic: things happen. Choosing the right financial model and anticipating what could go wrong are two of the most critical jobs for any project manager. A proactive approach here is non-negotiable. It ensures that when issues pop up—and they always do—your team is ready to tackle them head-on, protecting your timeline and your bottom line.

Understanding Common Pricing Models

No two projects are identical, so it makes sense that pricing structures aren't one-size-fits-all. The right model really depends on the project's scope, how clearly defined the work is, and how likely it is that things will change along the way. Good utility contracting companies know this and are usually ready to work within a few common frameworks.

The key difference between these models is how they allocate risk between you (the client) and the contractor. Getting this right is fundamental to building a fair agreement that works for your specific project.

Here are the three main models you'll run into:

-

Time and Materials (T&M): Think of this as a "pay-as-you-go" approach. You pay for the actual hours crews work and the cost of the materials they use, plus a pre-negotiated markup. T&M is incredibly flexible, which makes it perfect for jobs where the scope isn't fully baked or you know changes are coming. The tradeoff? Most of the budget risk falls on you, since the final cost isn't set in stone.

-

Fixed Price (Lump Sum): This is exactly what it sounds like. The contractor agrees to deliver a well-defined scope of work for a single, fixed price. This gives you budget certainty and shifts the risk of cost overruns to the contractor. It’s the best fit for straightforward projects with crystal-clear specifications. Be warned, though: any scope change will require a formal (and often costly) change order.

-

Unit Price: This model is a great middle-ground. The project is broken down into measurable "units" of work—like feet of conduit installed or number of poles set. Each unit has a fixed price, and the final bill is based on how many units are actually completed. It provides a nice balance of cost predictability and flexibility, making it a popular choice for large-scale builds where the exact quantities aren't known upfront.

The best pricing model is the one that best fits the project's reality. A well-defined, short-term project is perfect for a fixed price, while a complex, long-term network upgrade with many unknowns might be better suited for a T&M or unit price contract.

Proactive Risk and Contingency Planning

Let’s face it, utility construction is full of surprises. You might hit a massive stretch of underground rock nobody knew was there, or a key material could suddenly be back-ordered for weeks. Proactive risk management isn't just a good idea; it's essential for success. The goal isn’t to pretend you can eliminate every risk, but to identify the big ones and have a smart plan ready to go.

This work starts long before the first shovel hits the ground. It’s about getting the right people in a room to brainstorm what could go wrong, figure out how likely those things are to happen, and decide on clear, actionable contingency plans.

This kind of strategic foresight has never been more important. The value of utilities construction in the United States is projected to hit $189.2 billion. At the same time, contractors are dealing with a tough market, including supply chain chaos, high material costs, and labor shortages. As you can learn more about trends in utilities construction, these headwinds make robust risk planning an absolute must.

A solid contingency plan should always include:

- A Risk Register: This is your playbook. It documents every risk you've identified, its probability, its potential impact, and exactly how you plan to respond.

- Budget Reserves: Set aside a dedicated contingency fund—often 5-10% of the total project cost—to handle unexpected expenses without blowing up the entire budget.

- Clear Communication Protocols: When something goes wrong, you need to act fast. Establish a clear chain of command for reporting and addressing issues so that decisions can be made quickly.

By planning for risks before they happen, you empower your team to turn potential crises into manageable bumps in the road.

Common Questions About Working with Utility Contracting Companies

Even with a solid understanding of what utility contractors do, a few practical questions almost always come up before kicking off a project. Getting these details ironed out is key to moving forward with confidence. Here are some straightforward answers to the questions we hear most often.

What's the Real Difference Between a Prime Contractor and a Subcontractor?

Think of the prime contractor as the head coach of your project. They're the one you hire directly, and they hold the main contract. Ultimately, they are responsible for everything—the budget, the timeline, the quality of the work, and, most importantly, safety. They’re your single point of contact and the one accountable for delivering the finished project.

A subcontractor is more like a specialty coach brought in for a specific play. They are experts hired by the prime contractor for a particular task, like complex directional drilling, delicate fiber splicing, or high-voltage electrical work. The prime contractor manages all the subcontractors, making sure their work fits perfectly into the overall game plan and meets all safety and quality standards.

How Do Good Contractors Actually Handle Job Site Safety and Compliance?

For reputable contractors, safety isn't just a binder on a shelf; it's woven into everything they do. It starts with serious, ongoing training like OSHA certifications but becomes real through daily habits. Crews start each day with job site safety analyses (JSAs), often called "tailgate talks," to go over the specific risks of the work ahead.

The best firms have dedicated safety managers who show up unannounced to audit sites, ensuring rules are being followed and catching potential hazards before they become problems. On the compliance side, it's all about diligent paperwork—securing the right permits, following every environmental regulation, and managing traffic control precisely. This isn't just about avoiding fines; it's about making sure the project is executed professionally from start to finish.

What Are the First Steps to Get a Contractor on Board for a Project?

The whole process kicks off when you create a detailed Request for Proposal (RFP). This document is the playbook for your project. It needs to clearly define the scope of work, lay out the technical specifications, set a target timeline, and specify the qualifications you're looking for in a partner.

Once your RFP is ready, you'll send it out to a handful of pre-vetted contractors. After their bids come in, the real evaluation begins. This typically involves:

- Interviewing the top contenders to get a feel for their team and their problem-solving approach.

- Calling their references to hear directly from past clients about their real-world performance.

- Reviewing their safety records and program details.

Only after you’ve done this homework can you confidently select the right contractor and move into final contract negotiations.

How Do Contractors Deal with Surprises, Like Finding Unmarked Utilities?

This is where experience really shows. Any seasoned utility contracting company has a clear, practiced protocol for this exact scenario. The moment an unmarked utility is found, everything stops. The first priority is to halt all work in the immediate area and make it safe.

The crew immediately notifies the project owner and calls the local "One Call" or 811 service to get the utility owner on-site to identify and mark the line. The entire event is documented, usually leading to a change order to account for the new information. From there, a new plan is made to work around the obstacle safely, with constant communication about how the discovery might affect the timeline or budget. A professional response turns a potential disaster into a manageable hiccup.

For over 20 years, Southern Tier Resources has been the go-to partner for telecom carriers, data center operators, and network providers. We deliver complete engineering, construction, and maintenance services, all built on an unwavering commitment to safety, quality, and reliability.

Ready to build infrastructure you can depend on? Contact Southern Tier Resources to discuss your next project.