Fiber optic splicing is the art of joining two optical fibers together, end to end, creating a connection so seamless that light can pass through with almost no disruption. Imagine trying to weld two human hairs together so perfectly they become one. That’s the level of precision we're talking about, and it's absolutely critical for extending fiber networks or repairing broken cables without losing signal quality.

Understanding The Core Of Fiber Optic Splicing

At its heart, a splice isn't just a temporary connection you can plug and unplug. It's a permanent bond, engineered to last for decades and form the rock-solid backbone of our modern digital world. This is what separates it from a simple connector.

The entire process hinges on one thing: aligning the microscopic glass cores of two separate fibers with near-perfect accuracy. If there’s even the tiniest misalignment, a spec of dust, or an air gap, the light signal gets scattered or reflected. This causes data loss and seriously degrades network performance. A proper splice, on the other hand, lets that signal flow right through as if the junction wasn't even there.

Why Splicing Is Essential For Network Integrity

In any large-scale network, you simply can't build or maintain the infrastructure without splicing. It performs two absolutely vital functions.

- Extending Network Reach: Fiber optic cable comes on spools of a set length, usually a few kilometers. To build long-haul networks that cross cities, states, or even countries, technicians have to splice these individual segments together into one continuous line.

- Repairing Damaged Cables: Let's face it, accidents happen. A construction crew with a backhoe is a fiber network's worst enemy. When a cable gets cut, splicing is the only practical way to fix it, fusing the broken ends back together to restore service.

This constant need for building and repairing fiber infrastructure is a massive driver of investment. The global fiber optic cable market hit $6 billion in 2020 and continues to climb. Every mile of new fiber optic construction requires countless splices, fueling the demand for expert technicians who can execute these delicate procedures perfectly every time. You can read more about this growth trend on opelink.com.

The Two Main Splicing Methodologies

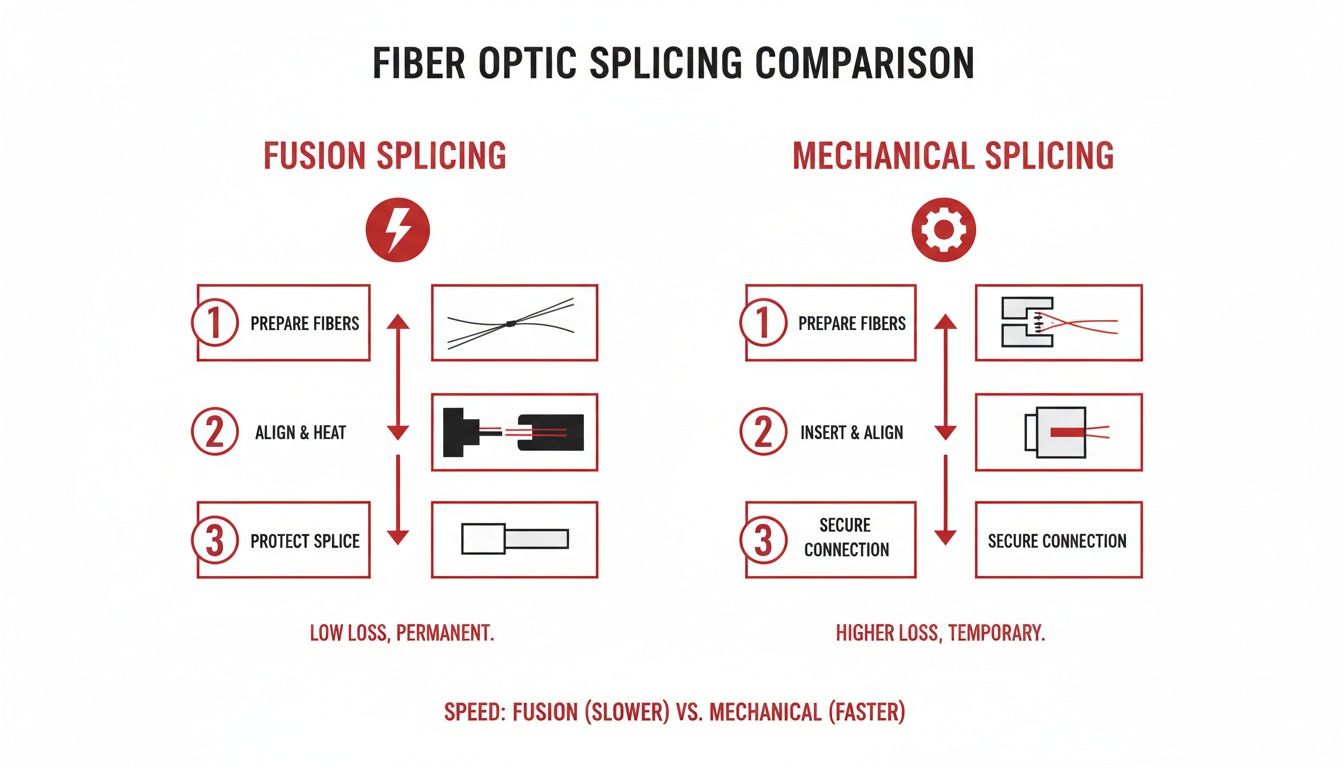

While the objective is always a perfect, permanent join, technicians rely on two main methods to get the job done. Each has its place, and the choice often depends on the project's specific needs for performance, speed, and cost.

Fusion Splicing: This is the industry's gold standard. It uses a high-precision machine to perfectly align the two fiber ends and then zaps them with an electric arc. This melts the glass, permanently fusing them into a single, continuous strand. The result is an incredibly strong connection with the lowest possible signal loss—typically less than 0.1 dB.

Mechanical Splicing: This approach uses a small mechanical housing to align the fibers. A special index-matching gel inside the housing helps bridge the gap between the two ends, minimizing signal reflection. It's much faster than fusion splicing and doesn't require expensive equipment, making it a great option for emergency repairs or in situations where a top-tier connection isn't absolutely critical.

Choosing Your Method: Fusion Splicing Vs. Mechanical Splicing

When you need to join two fiber optic strands, the goal is to create a connection so perfect that light passes through it with almost no disruption. How you achieve that connection is a critical decision. The two leading techniques, fusion and mechanical splicing, each have their own place in a network technician's toolkit, and the right choice often comes down to balancing long-term performance against the need for speed and convenience.

The Precision Of Fusion Splicing

For permanent, high-performance connections, fusion splicing is the undisputed champion. This method uses a sophisticated machine called a fusion splicer to perfectly align the cores of two fibers before melting the glass ends with an electric arc. The result is a seamless weld, creating a single, continuous piece of glass.

Think of it as microscopic surgery. The join is so clean and strong that it often has a lower signal loss—typically less than 0.1 decibels (dB)—than a factory connector. This near-flawless connection is the standard for critical infrastructure like long-haul telecom routes, data center backbones, and carrier networks where preserving every bit of signal strength is paramount.

The magic of fusion splicing lies in its automated precision. While a technician prepares the fiber, the splicer itself does the heavy lifting, using tiny motors for sub-micron alignment before striking the arc.

This approach creates a bond that is virtually identical to an unbroken fiber, delivering the lowest possible signal loss and minimal back reflection. That's why it's essential for high-speed networks and sensitive analog systems, like some video feeds, where reflections can wreak havoc on signal quality. The upfront investment in equipment and training pays for itself in unparalleled reliability.

By creating a single, homogenous glass structure, fusion splicing ensures the splice point will not degrade over time due to temperature changes or vibration. It delivers the ultimate peace of mind for permanent network infrastructure.

The Speed And Simplicity Of Mechanical Splicing

On the other end of the spectrum is mechanical splicing, a faster and more straightforward field solution. Instead of welding the fibers together, a mechanical splice is a small, precision-engineered housing that aligns the two fiber ends and holds them securely in place.

Inside this housing, a special index-matching gel fills the microscopic air gap between the fibers. This gel helps trick the light into making the jump from one strand to the other with less disruption. It’s a clever, effective solution that doesn't require a costly fusion splicer.

This method's speed and simplicity make it perfect for certain situations:

- Emergency Repairs: When a line goes down, a mechanical splice can get the network back up and running in minutes.

- Temporary Connections: It's a great fit for temporary event setups or in final "fiber-to-the-home" (FTTH) drops where a slightly higher-loss connection is acceptable.

- Tough Environments: In places where it’s just not practical to set up a fusion splicer, this method provides a reliable alternative.

The trade-off, of course, is performance. Mechanical splices introduce more signal loss, usually between 0.2 dB and 0.75 dB, and can be more vulnerable to performance issues caused by temperature shifts or vibration over time.

A Side-By-Side Comparison

So, which one is right for your project? The answer depends entirely on your specific needs, budget, and long-term performance goals. This decision is a fundamental part of the overall fiber optic network design process, as it directly impacts both cost and reliability.

To make it clearer, let's break down the key differences.

Fusion Splicing vs Mechanical Splicing At A Glance

| Attribute | Fusion Splicing | Mechanical Splicing |

|---|---|---|

| Performance | Extremely low insertion loss (<0.1 dB), minimal reflection. | Higher insertion loss (0.2 dB – 0.75 dB), moderate reflection. |

| Durability | Permanent and highly stable; stronger than original fiber. | Less durable; susceptible to temperature and vibration changes. |

| Upfront Cost | High (fusion splicer costs thousands of dollars). | Low (requires only basic hand tools and the splice itself). |

| Per-Splice Cost | Very low (only a splice sleeve is needed). | High (each mechanical splice unit is a consumable part). |

| Speed | Slower; requires machine setup and careful preparation. | Very fast; can be completed in just a few minutes. |

| Skill Level | Requires trained technicians to operate equipment. | Can be performed with minimal training. |

| Ideal Use Case | Long-haul networks, data centers, main backbone cables. | Emergency repairs, FTTH drops, temporary installations. |

This choice between a permanent weld and a quick-fix mechanical housing highlights how far the technology has come. Since its commercial beginnings—when companies like Sumitomo Electric Industries launched early models like the TYPE-3 fusion splicer in 1980—the process has transformed from a manual art into a highly automated science.

Today, smart diagnostics and automation have driven 45.6% of technical upgrades in the splicing market, leading to faster and more reliable results. You can read more about this evolution at global-sei.com. This progress is exactly why working with modern, well-maintained equipment is non-negotiable for achieving world-class network performance.

The Anatomy Of A Perfect Fiber Optic Splice

A perfect fiber optic splice isn’t just a matter of hitting a button on a machine. It's a disciplined, multi-step process where meticulous prep work by a skilled technician makes all the difference. While the fusion splicer handles the final weld, the quality of that connection hinges entirely on the stages leading up to it.

Think of it as a delicate dance of stripping, cleaning, and cleaving—each step building on the last to create a flawless pathway for data to travel at the speed of light.

Step 1: Cable And Fiber Preparation

The journey to a perfect splice begins by getting to the fibers themselves. They’re buried deep inside the main cable, protected by an outer jacket, strength members, and buffer tubes. A technician has to carefully score and peel back these protective layers without nicking the fragile glass strands within.

Once the individual fibers are free, the real precision work starts. Each one is covered in a protective acrylate coating that needs to go. Using a specialized tool called fiber strippers, the tech gently removes this coating, finally revealing the bare glass cladding and core. This is a make-or-break moment; any leftover coating will just burn up and contaminate the splice, causing high signal loss or even a complete failure.

Step 2: Meticulous Fiber Cleaning

With the bare glass exposed, the next priority is making it spotless. We're talking microscopically clean. A single speck of dust, a smudge from a fingerprint, or a trace of stripped coating can scatter or reflect light, killing the signal quality.

To get it right, technicians use lint-free wipes and 99% isopropyl alcohol to clean each fiber. The trick is to wipe once, in a single, smooth motion, so you don't accidentally re-contaminate the surface. It sounds simple, but this step is absolutely vital for ensuring the glass is pristine for the most critical phase.

This visual breakdown compares the two primary splicing methods, showing how their processes and results stack up.

As you can see, fusion splicing demands more prep work, but the payoff is a superior, permanent connection—exactly what you need for critical network infrastructure.

Step 3: Precision Cleaving For A Flawless End-Face

If you ask any experienced fiber tech, they’ll tell you this is the single most important part of the whole process. Cleaving isn't cutting; it's the controlled breaking of the fiber to create a perfectly flat end-face, precisely at a 90-degree angle to the fiber’s core.

A high-precision cleaver makes a tiny score on the glass, and then controlled tension is applied. The result is a clean, mirror-like break.

If that cleave is off by even one degree, or if the end-face has the slightest chip, the fibers won't line up correctly. This creates an air gap or core misalignment that directly causes high signal loss and back reflection. A bad cleave guarantees a bad splice, no matter how sophisticated your fusion splicer is.

Step 4: Alignment, Fusing, And Protection

Now, with two perfectly prepared fibers, it's time for the main event. They are carefully placed into the holding blocks of the fusion splicer. The machine takes it from here, using automated cameras and micro-motors to align the fiber cores with sub-micron accuracy. It even performs a tiny "cleaning arc" right before the splice to zap any last-minute dust particles.

Once aligned, the splicer unleashes a powerful electric arc, melting the two glass ends and permanently welding them into one continuous strand. The machine then does a quick tension test to confirm the weld is solid and gives an estimated loss value for the new splice.

The job isn't done yet. That splice point is now exposed and fragile. A technician slides a heat-shrink splice protection sleeve over the area and places it into a small oven built right into the splicer. The sleeve shrinks down, forming a rigid, durable shield that protects the connection from moisture and physical strain for the life of the cable.

The Essential Toolkit For Professional Fiber Splicing

You can't achieve a perfect splice with subpar equipment. It's just that simple. Much like a surgeon needs precision instruments, a fiber technician’s success hinges on a specialized toolkit. Investing in high-quality, well-maintained tools isn’t just a good idea—it’s the only way to build a network that will stand the test of time.

The star of the show is, without a doubt, the fusion splicer. This sophisticated machine is the heart of the entire operation. It handles the microscopic alignment of fiber cores and uses an electric arc to fuse them into one seamless connection. While today's splicers are impressively automated—giving you loss estimates and strength tests in moments—their results are only as good as the prep work that comes before.

Core Preparation Tools

Before that high-tech splicer can do its job, the fiber itself has to be flawlessly prepared. This means getting your hands on a few essential tools to create a perfectly clean and precisely cleaved fiber end. If you mess up this first step, even the best splicer in the world can't save the splice.

These are the non-negotiables for fiber prep:

- Fiber Optic Strippers: Forget standard wire strippers. These are specially designed to carefully remove the outer buffer and inner acrylate coatings without nicking or weakening the fragile glass fiber hidden inside.

- Isopropyl Alcohol Wipes: Only 99% pure isopropyl alcohol and completely lint-free wipes should ever touch the glass. This combination is critical for wiping away any dust, oils, or debris left over from the stripping process.

- High-Precision Fiber Cleaver: This might be the most important hand tool of them all. It’s responsible for scoring and breaking the fiber to create an absolutely flat, 90-degree end-face. A top-notch cleaver is the single biggest contributor to a low-loss splice.

Splicing and Protection Essentials

With the fiber prepped and ready, you need a couple more items to finish the job and protect your work. These consumables are every bit as crucial as the hardware.

The splice protection sleeve is a small but mighty component. It’s a heat-shrink tube with a tiny steel rod for strength and an inner tube that melts when heated. After the splice is made, you slide this sleeve over the connection and place it in the splicer’s built-in oven. The result is a tough, permanent shield that protects the fragile junction from moisture and physical stress for years to come.

The entire process of preparing the cable and using these tools is a discipline in itself. For a deeper look into the broader workflow, our guide on how to install fiber optic cable provides essential context for field operations.

Testing and Validation Equipment

At the end of the day, a splice is only as good as its measured performance. You can't just eyeball it and hope for the best; technicians rely on specialized test gear to prove the connection meets strict industry standards.

- Visual Fault Locator (VFL): This is a simple yet incredibly handy tool. It shines a powerful red laser down the fiber, making any major flaws—like breaks, tight bends, or a botched splice—glow bright red. It's perfect for quick, on-the-spot checks.

- Optical Time Domain Reflectometer (OTDR): For a true professional sign-off, you need an OTDR. This is the definitive validation tool. It sends pulses of light through the fiber and analyzes the signals that bounce back, creating a detailed "map" of the entire cable. It allows a technician to measure the exact signal loss (insertion loss) at each splice and pinpoint its exact location down the line.

How To Validate Splice Quality With Testing

You can’t just eyeball a fiber splice and call it a day. A connection might look perfect, but its true quality is measured in fractions of a decibel. This is where meticulous testing comes in, transforming a physical connection into a certified, high-performance link that you can count on.

The single most important metric we look at is Insertion Loss (IL). Think of it as the tiny bit of signal strength that gets lost as light crosses the splice point. Ideally, you want this number to be as close to zero as possible. For a top-tier fusion splice, industry standards demand an IL of 0.1 decibels (dB) or less. Anything higher than that is a red flag, pointing to a flaw that could cause serious network headaches down the road.

Using An OTDR To See Inside The Fiber

So, how do we measure something so small? We use a specialized piece of equipment called an Optical Time Domain Reflectometer (OTDR). The best way to think of an OTDR is like radar for a fiber optic cable. It shoots a pulse of light down the fiber and meticulously analyzes the reflections that bounce back from every connection, bend, and imperfection along the way.

This data creates a visual map of the entire cable run, called an OTDR trace. For a technician, this trace is an invaluable diagnostic tool. It lets us:

- Pinpoint Splice Locations: Every splice shows up as a specific event on the trace, telling us exactly where it is.

- Measure Insertion Loss: The OTDR calculates the precise drop in signal power at the splice, giving us that critical IL value.

- Identify Other Faults: It's not just for splices. The trace will also reveal problems like sharp bends (macrobends), faulty connectors, or even a complete break in the line.

The Importance Of Optical Return Loss

There’s another key measurement we can’t ignore: Optical Return Loss (ORL). While insertion loss is about the signal that gets lost moving forward, ORL measures the amount of light that gets reflected backward toward the source. Why does this matter? High back reflection can wreak havoc on sensitive laser transmitters, corrupting data and causing major network instability.

A clean, properly executed fusion splice will have almost no back reflection, which is crucial for maintaining signal integrity. This is why testing isn't just a final step; it's a fundamental part of building a network that will perform flawlessly for years, even decades.

Protecting these validated splices is just as critical. That’s why the global market for fiber splice closures—the rugged enclosures that protect these connections—was valued at USD 2.9 billion and is expected to climb to USD 4.8 billion within the next decade. This explosive growth underscores the industry's focus on long-term reliability and the need for expert partners who can handle the entire lifecycle of a network build, not just the splicing itself. You can explore more about these market trends and see what they mean for modern infrastructure projects.

Frequently Asked Questions About Fiber Optic Splicing

Even after getting the basics down, you’ll probably still have a few questions about how fiber optic splicing works in the real world. Let's tackle some of the most common ones that pop up.

What’s The Main Difference Between Splicing And Using A Connector?

Think of it like this: splicing is a permanent weld, while a connector is like a plug you can easily connect and disconnect.

A splice creates a permanent, ultra-low-loss join between two fibers, fusing them into what is essentially a single, continuous strand of glass. This is the go-to method for long-haul networks or permanent repairs where you absolutely cannot compromise on signal quality.

Connectors, on the other hand, are built for flexibility. You'll find them on patch panels or equipment where you need the ability to plug and unplug cables. This convenience comes at a cost, though—connectors always introduce more signal loss than a good splice.

How Long Does A Fusion Splice Last?

A well-executed fusion splice, properly sealed in a heat-shrink sleeve and secured inside a splice closure, is built to last as long as the cable itself. We're talking 25 years or more. In fact, a good splice is often physically stronger than the original fiber, so you can count on it for incredible long-term reliability.

When a fusion splice is completed and protected correctly, it forms a bond that is both physically strong and optically pure. This durability is why it is the standard for carrier-grade network construction.

Can You Splice Different Types Of Fiber Optic Cables Together?

You can physically fuse them, but you really shouldn't. It’s strongly discouraged.

Trying to splice different fiber types—like single-mode to multi-mode—is a recipe for disaster. You'll end up with massive signal loss and terrible performance. The problem is that the fiber cores are different sizes, so the light simply can't transition between them cleanly. For a clean, low-loss link, always splice identical fiber types.

What Is The Most Common Cause Of A Bad Splice?

Nine times out of ten, a bad splice comes down to one thing: a poor cleave. If the end of the fiber isn't cut perfectly flat at a clean 90-degree angle, the two pieces just won't line up properly in the fusion splicer.

That tiny imperfection is all it takes to create a flawed joint that scatters the light signal, causing high insertion loss and back reflection. The runner-up cause is simple contamination—a speck of dust or a fingerprint on the fiber end can ruin the fusion. This is why a technician's skill and meticulous prep work are absolutely non-negotiable.

Executing a perfect splice takes more than just the right equipment; it demands expertise, precision, and a solid grasp of network engineering. For complex projects that need to be done right from the start, from design all the way to final testing, working with an experienced partner is critical. Southern Tier Resources delivers end-to-end fiber optic construction, splicing, and maintenance, ensuring your network is built to the highest standards. Learn how we can support your next infrastructure project.